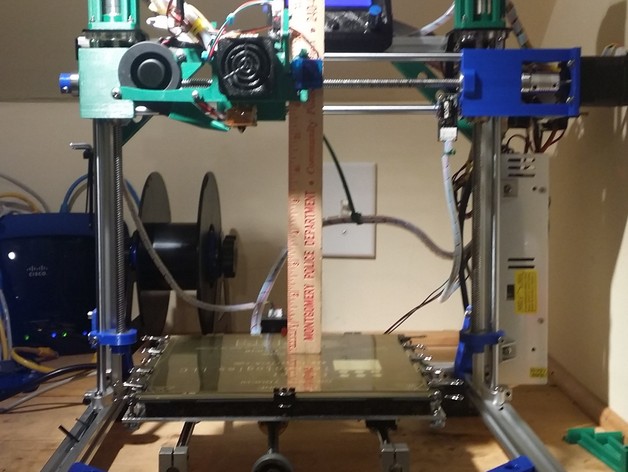

Folger Technologies i3 2020 Full Lead Screw Upgrade on all axis

thingiverse

It appears that you've compiled a comprehensive list of parts and components required to build a 3D printer, specifically a Prusa i3 rework. Here's a summarized version: **Essential Components:** 1. **Lead Screw Nut**: 1x (for anti-backlash on Y-axis) 2. **Bearings for Y Axis**: 2 pieces 3. **Stepper Motor Couplings**: 4x 4. **Z Axis Motor Risers**: 5. **Corner Braces**: 4x 6. **Fan Bracket & Servo Arm for Z probe**: 7. **Blower Duct**: 8. **Dual Bearing mount for Y table**: **Stepper Motors:** 1. **Replacement Stepper Motors**: (replacing all existing motors) **Thrust Washers and Collars:** 1. **4x Thrust Washers**: 2. **1x Set of 4 Thrust Washers**: **Igus Bearings:** 1. **12 Igus Bearings**: **Skate Bearings:** 1. **6x 8MM ID Skate Bearings**: **Optional Components:** 1. **Anti-Backlash Nut & Spring**: 3x (if used) 2. **Z Leadscrew Anti-Backlash Rev2**: (requires mirroring for left and right sides) **Miscellaneous:** 1. **3mm / 4mm Screws and T-nuts**: several 2. **Power Supply and Ramps**: moved to outside 2020 frame Please note that some of these components might be optional or have alternatives, and it's essential to review the assembly and make a checklist before starting the build. Also, there are links provided for various parts and components on Amazon, Folgertech, and Thingiverse.

With this file you will be able to print Folger Technologies i3 2020 Full Lead Screw Upgrade on all axis with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Folger Technologies i3 2020 Full Lead Screw Upgrade on all axis.