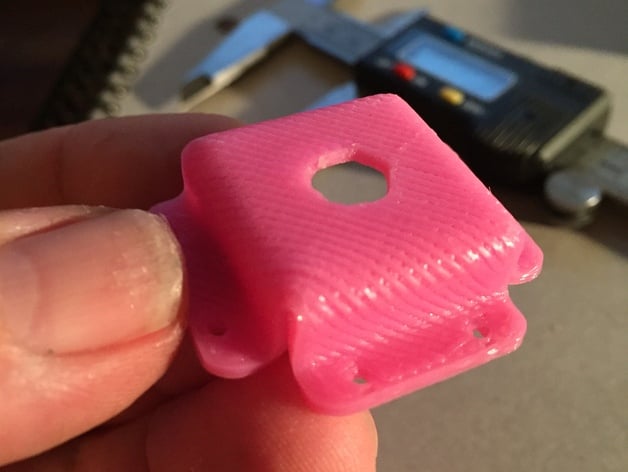

Formed 3D printed bracket

thingiverse

I wanted to conduct a test of various processes to enhance the strength and speed of 3D printed parts. Several ideas emerged from this experiment, which I'm excited to share with others. My goal is to introduce efficiency and quality improvements that can be applied to metalworking in 3D printing, potentially propelling this technology forward. By combining processes such as forming and stamping on flat blanks, we may achieve stability for weaker prints. For instance, the bracket featured here took only 10 minutes to print in a flat pattern and just 30 seconds to form into its current shape after creating the necessary tool (2 hours). If I were printing this formed part, it would take over an hour and be extremely weak. Printing at a 45-degree angle significantly increased the strength of the legs and minimized deformation when forming it. This bracket is remarkably strong. By using nylon and the boiling method, we can further strengthen the print. Although I didn't have time to perform a thorough strength test against standard printed versions, I can confirm that this part supports an impressive 60 pounds of weight. Incorporating formed gusset darts in the bends would easily boost its strength by 50%. Thinking outside the box and applying processes like these will drive innovation and enable easier high-volume production if needed. Keep an eye out for future posts showcasing more examples. Printer Settings: * Printer Brand: SeeMeCNC * Printer Model: Rostock MAX * Rafts: Doesn't Matter * Supports: No * Resolution: 0.2mm * Infill: 100% Post-Printing Instructions: 1. Load the flat blank into the die section of the tool. 2. The pic shows the part after forming. 3. Secure the part between the punch and die with a clamp, just snugly. 4. Dip the clamp end and part into boiling water for about 10-30 seconds while slowly clamping them together. 5. Once the punch and die are fully seated, remove from the water and run under cold water for 10-20 seconds. 6. Take apart the tool and retrieve the part!

With this file you will be able to print Formed 3D printed bracket with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Formed 3D printed bracket.