FormLabs Form 1 Leveling Jig

thingiverse

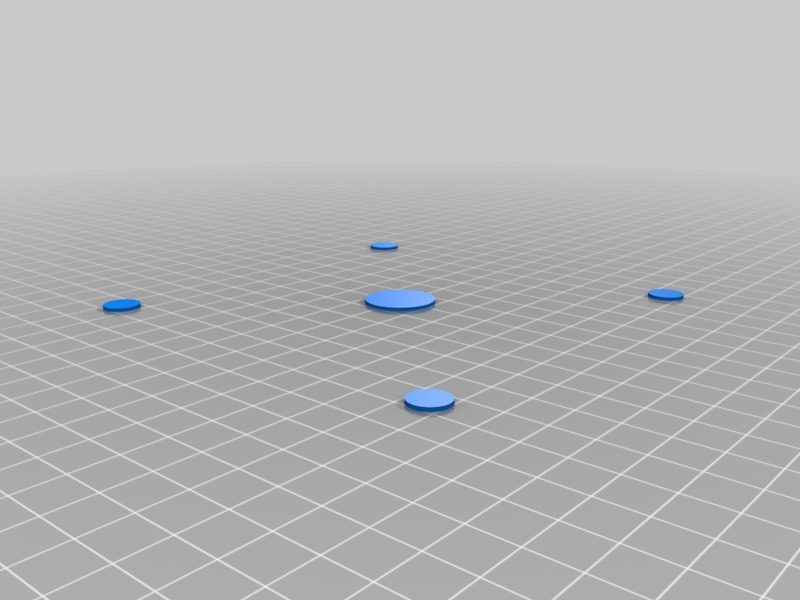

If you re-pour your PDMS layer, make your own vats, or use 3rd party vats with your Form 1, chances are your build platform can use a good leveling. This calibration jig places four 10mm x 1mm disks in the corners, and one 20mm x 1mm disk in the middle of your build platform. Calibration means that the build platform is parallel to the surface of the PDMS layer of your vat, and at the nominal distance. This procedure is not difficult, but does require patience, steady hands, and attention to detail. Calibration in Summary 1. Print the calibration jig. 2. Remove disks one at a time, and measure the thickness using a caliper. 3. Use a 7mm wrench to adjust the leveling nuts in each corner. 4. Print the calibration jig again. 5. Measure disk thickness again. 6. Adjust leveling again if needed. A few words on leveling with the 7mm wrench. Leveling is adjusted by tightening or loosening the four Nylock nuts located in the four corners of the tilt platform, under the vat. A full turn of the nut is equal to 0.7mm. Since the nut has six sides, it is useful to exploit the fact that 1/6th of a turn will adjust the level by 0.116mm. It is possible to turn these leveling nuts with the case fully assembled, but it does bring you into close proximity of the main mirror, so I recommend taking the covers off to preform the leveling step. Some day soon, I will make a video of the process.

With this file you will be able to print FormLabs Form 1 Leveling Jig with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on FormLabs Form 1 Leveling Jig.