Gear Ratio

myminifactory

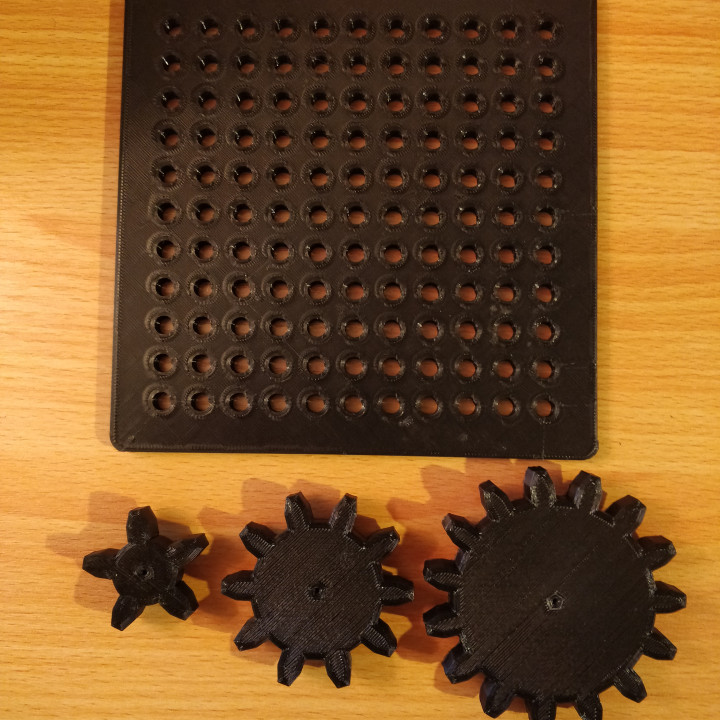

This design of a pegboard and gears is to teach how the use of different size gear are apple to produce different amounts of speed and torque depending on the gear ratio. This is supposed to help teach that by using a 5 toothed gear and a 15 toothed gear that are messed together that there would be a 3:1 gear ratio. Meaning that the 5 toothed gear would need to rotate 3 time before the 15-toothed gear would rotate one time. This allows for a greater torque to be outputted from the gear system than what would be able to be produced by just the 5 toothed gear. A simple equation can be used to calculate different gear ratios depending on the number of teeth that are on each gear. Gear ratio= where is the number of teeth on the output gear and is the number of teeth on the input gear. So, if 15 teeth are on the output gear and 5 teeth are on the input gear you will get a gear ratio of 3. Additional information and equation involving gear ratios can be found here https://en.wikipedia.org/wiki/Gear_train. The 3D printing of the Peg board and gear took approximately 10 hours at a fill density of 10% to reduce the amount of material that is used. The total cost in material for printing the peg board and three gears comes out to 140 grams of material which costs about $2.40. With similar products being priced at $28.00 https://www.lakeshorelearning.com/products/ca/p/PP845/?utm_source=google&utm_medium=ppc&utm_campaign=PLA&CATARGETID=520011010000097124&CADevice=c&gclid=Cj0KCQjwtsv7BRCmARIsANu-CQdLh4wptZlS 6v1xyefSt9UZM_t59IPZQ4zftzg9P1DOGZVRrl61ZEaAnCWEALw_wcB, so this comes out to a cost saving of $25.60.

With this file you will be able to print Gear Ratio with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Gear Ratio.