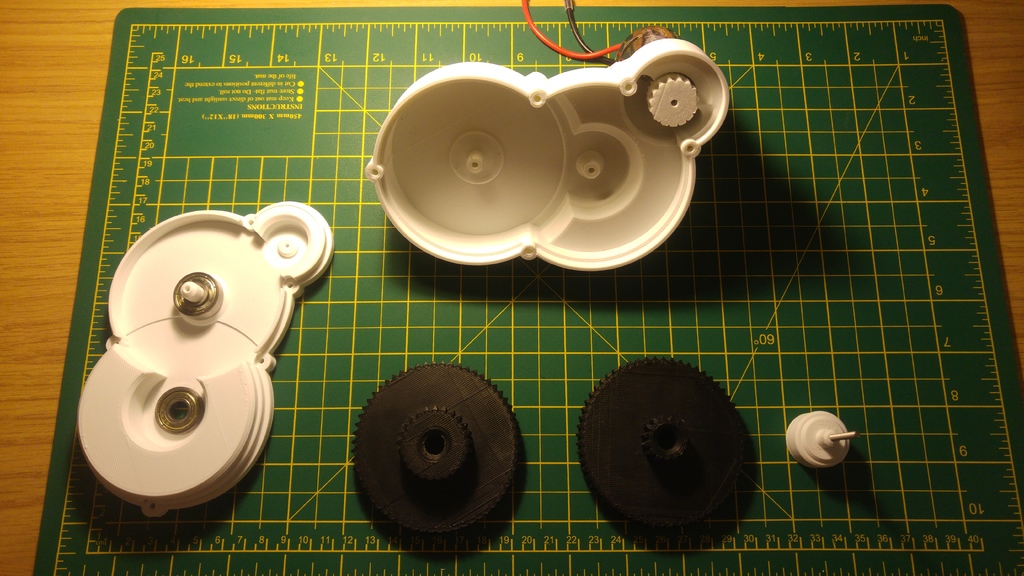

Gearbox 9.6:1

thingiverse

I finally have got my service up and running, please visit https://www.blueboxgoblin.co.uk/ for some other interesting projects. Gearbox I've just changed Gearbox status to completed. I'm not planning to make any modifications in near future as I'd like to focus on other stuff. - Please use link to access other tank's bits and pieces: https://www.thingiverse.com/thing:2633865 Update 20.11.17: - https://youtu.be/bXt7yj8lu30 lub grease test Update 15.11.17: -I'll upload Gearbox test (lubrication grease) shortly. It seems to run less noisy. Update 13.11.17: - Gearbox test (lubrication oil) https://youtu.be/R7k5w_c8Ybk https://youtu.be/z1PMqtSG_rE Update 12.11.17: - Flexi motor frame. Please use link below for all frame files: https://www.thingiverse.com/thing:2641429 Update: 08.11.17: - Following comments I've made upgraded gears, so they have prime number of teeth. I've tested it and it seems to work fine as first version. After upgrade ratio's 12:1 Please use link below for upgraded gears: https://www.thingiverse.com/thing:2633942 Update: 07.11.17: - New version of cap. File name: Cap 15 inner teeth v2.stl This one is a bit longer and has got triangle shape for better grip. I'm currently working on RC tank/crawler for my son. The biggest challenge so far has been a gear box. Current version has got 9.6:1 ratio, and in future I wish to change it to 36/38:1, but at the moment have to focus on vehicle itself. Gear box seems to be quite massive 160x100x35mm. Idea was it could fit 1:10 or 1:16 tank. All parts have been made of ABS. PLA would be good too, but it works better for me with ABS. As this is still work in progress I'll be updating as often as possible. Parts list: -Base; stl file with additional 0.2 height brim; -Lid; with 2 lubrication points; stl file with additional 0.2 brim; -Drive pinion 15 teeth 1.25mm module; this's real troublemaker. In first parts were printed in PLA, but due to lack of heat resistance pinion was melting around motor's shaft. I needed to go around, so I made gear with crown which fits 15 teeth 0.6mm module metal drive pinion. No temperature related problems so far; I've attached two different files so they should fit different pinion shapes. -Gear one double 60 and 25 teeth 1.25mm module -Gear two double 60 and 15 teeth 1.25mm module -Cap 15 inner teeth You'll need: - 2x M3x10mm screws to fit motor - 7x M3x40mm screws - 6x M3 nuts - 3x 608zz ball bearings (OD 22mm, ID 8mm, Thickness 7mm) - 15 teeth 0.6mm module drive pinion I use 65t crawler motor by RC4WD Any suggestion please leave a comment and I'll answer asap. Hopefully will get back soon with frame/stand - I was thinking about flexi material so it may reduce vibration and noise.

With this file you will be able to print Gearbox 9.6:1 with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Gearbox 9.6:1.