Geared 1.75mm Bowden Feeder for 3D Printer (suitable for Flexible filament)

thingiverse

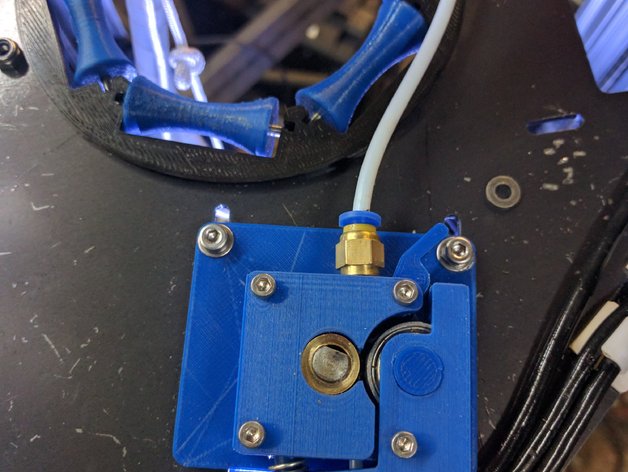

I've built (and designed) my own Delta Printer, wanting something better than the current crop within my price range. Initially I bought a cheap aluminium feeder - which turned out to be less than ideal! It's main issue was that the filament path was not straight and not guided as it passed through the body. If too much pushing force is applied, the filament buckles and the print is ruined! On my original (Ultimaker) I printed an iRoberti feeder, which is excellent! However, there didn't seem to be a 1.75 version which used the push-fit connectors for bowden tube. I figured, if I had to modify it, I might as well start from scratch! Originally I used this with a regular NEMA17 motor - which worked fine. The parts pictured were printed using it (in PolyMax filament). I want to push the speed of my printer and a standard NEMA17 just doesn't seem to develop the torque I require. Instead, I'm using a NEMA17 with a 5:1 reduction gearbox - so about 5x the torque. However, this will work just as well geared or not. In addition to the motor, you need: 4 x M3 x 25mm screws 4 x M3 Nyloc Nuts (Plain nuts will just loosen within minutes!) 1 x 22mm OD, 8mm ID, 7mm Thick bearing (608-ZZ type (ZZ just means metal shields as they run more freely than 2RS type, rubber shields) 1 x Drive Gear suitable for your motor (*See Below) 1 x 4mm, M6 Push Fit connector for Bowden tube. 1 x 9mm OD 20-25mm long spring (from an eBay spring assortment) 1 x M4 x 16 Screw (for tension adjustment) 1 x M4 Plain Nut (for tension adjustment) (Optional) Short length of 3mm OD Bowden tube to guide the filament in. And, of course a 3D Printer to print the bits! The Drive Gear must be no more than 12.5mm OD. Most of the Mk7 & Mk8 types are suitable. Most motors have a 5mm or 6mm shaft (you'll have to measure) whereas my geared motor has an 8mm shaft. My 8mm bore gear has not arrived yet which is why it's missing in the photos! Part 'Stepper Mount Temp.STL' is designed to mount on to my printer - but you should be able to adapt this to yours, if it's needed at all. The four inner holes are correct for the geared NEMA17. The four outer ones for an ordinary NEMA17 motor. The filament is guided all the way through, apart from about 1mm either side of the drive gear. I've found it works well with PolyFlex and NinjaFlex - so probably most of the others too. I heated up the tip of an M6 bolt (with a lighter) and screwed that in first to melt a thread - but if you're careful you can just screw it in letting it cut it's own thread as it goes. The design incorporates a release 'switch' which pushes the bearing away from the filament and holds it released. Handy for manually loading filament. I just used a random spring I found in an assortment bought from eBay years ago. It needs to be no more than 9mm OD and greater than 6mm bore. It doesn't need to be particularly strong. Mine is stronger than it needs to be. I hope this proves useful! Feel free to share, distribute, hack! Print Settings Printer: Simon's Delta Rafts: No Supports: No Resolution: 0.1mm Infill: 40% Notes: I would either print this solid or with a fair bit of in-fill as there is a fair amount of stress on the components.

With this file you will be able to print Geared 1.75mm Bowden Feeder for 3D Printer (suitable for Flexible filament) with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Geared 1.75mm Bowden Feeder for 3D Printer (suitable for Flexible filament).