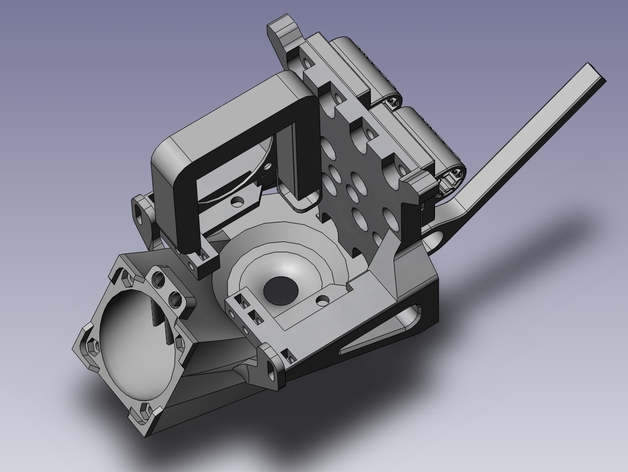

Geeetech i3 X - X carriage set with circular fan duct

thingiverse

An alternative X-carriage is made for Geeetech Prusa i3 X, designed with some minor advantages over stock Geeetech carriage sets: easier removal of extruder, smoother rod separation at 45mm instead of the default 70mm. The backplate features cable gaps and M3 screw holders, allowing cables to be fixed at the back side. A fan shroud cools the hot-end a bit, with three sets of frontal mounting holes for easy assembly. The circular fan duct provides uniform cooling flow, keeping a distance of 3mm from the print bed to avoid damaging binder clips. The design reduces weight compared to solid acrylic and hides screw heads within the backplate. Limitations include using low-profile SC8UU bushings with provided belt fixation, potentially needing shorter screws, and limiting X distance due to the back cable holder. The circular fan duct requires careful placement near the heater block to avoid melting. Print settings: versions are available with and without manual support for the backplate and fan duct. The circular fan duct has internal supports and bridges; select proper orientation for printing. Post-printing instructions include inserting M3 nuts into slots, gluing them in place, and attaching a heat-isolating cardboard ring to the fan. Adjust the fan's height carefully to maintain 1mm distance from the heater block.

With this file you will be able to print Geeetech i3 X - X carriage set with circular fan duct with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Geeetech i3 X - X carriage set with circular fan duct.