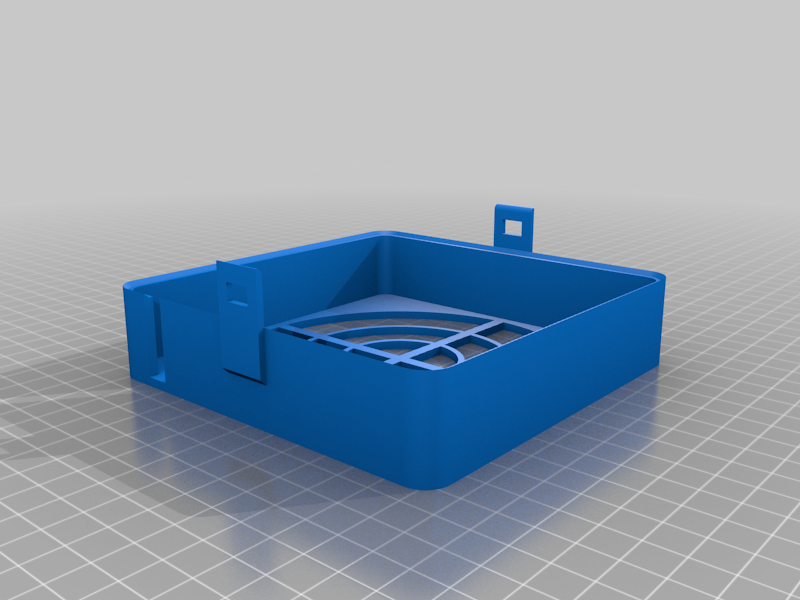

HEPA & Carbon Filter 120mm Fan Bi-Directional Air Scrubber (mounting optional)

thingiverse

Needed a simple air scrubber for inside an enclosure, wasn't requiring an extractive style venting system due to the materials being printed but wanted something that would filter the air trapped inside. An air scrubber fit the bill and allowed temperatures to be maintained within the enclosure. Model can be mounted as shown in the picture or sit on the base of your enclosure, air flow is bi directional, just switch the fan direction depending on what you prefer. In the example case air is being pulled into the filter assembly from the top and sucked out the bottom. My preference is non filtered air contacting the HEPA filter first then the carbon filter. This in NO WAY replaces a true venting system, wouldn't recommend using this style of filter if you're printing with materials that release harsher components (ASA, resins, etc…). Currently printing with PLA, PETG and TPU so felt safe using a scrubber rather than a venting system. No air quality testing has been performed but the smell has been noticeably reduced after opening the enclosure door, the fan runs for a good 20 minutes after printing before opening the enclosure door, this also allows time for parts to cool before being removed from the printer bed. Parts Required 120mm fan (used a cheap fan off Amazon) HEPA and Carbon Filters (purchased a large filter set and cut to fit the Filter Holder, Filter Holder is the same size as the 120mm fan) Printed Parts Optional Parts 4 x Screws (made the holes for #8 screws, my flows are off so the holes ended up fitting M3 screws, either way you could add washers or drill a larger hole if mounting on the top of the enclosure Buck converter to regulate fan speed (used a 12V source to match the fan requirements, dropped voltage to the fan to reduce drafts) Additional wiring to power the fan Print/Slicer Settings 0.2mm Layer Height 4 Walls (decreases print time) Infill was set to 20% but you could get away with lower Supports required (holes for the clips, mounting brackets and air flow holes needed support) Brim was used to prevent lifting but isn't necessary Used PETG in case enclosure temperatures increased past 60°C but PLA should work if your enclosure doesn't reach high temps Suggestions Print the two Calibration prints first to ensure the fan you're using fits correctly, fan should be flush with the flat portion of the Fan Holder wall, the second Calibration print is to ensure the clips will function correctly and the fan will sit properly. Increase the number of walls to reduce printing time (print time was reduced by a couple hours between 2 and 4 walls on standard settings for a 0.4mm nozzle) Blowback was noticeable at full fan speed when pushing air through the filters, be cautious if cold air is being pulled into your enclosure Initially this was designed for 1 x HEPA filter and 4 x carbon filters, currently running with only 2 x carbon filters to increase air flow through the filters

With this file you will be able to print HEPA & Carbon Filter 120mm Fan Bi-Directional Air Scrubber (mounting optional) with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on HEPA & Carbon Filter 120mm Fan Bi-Directional Air Scrubber (mounting optional).