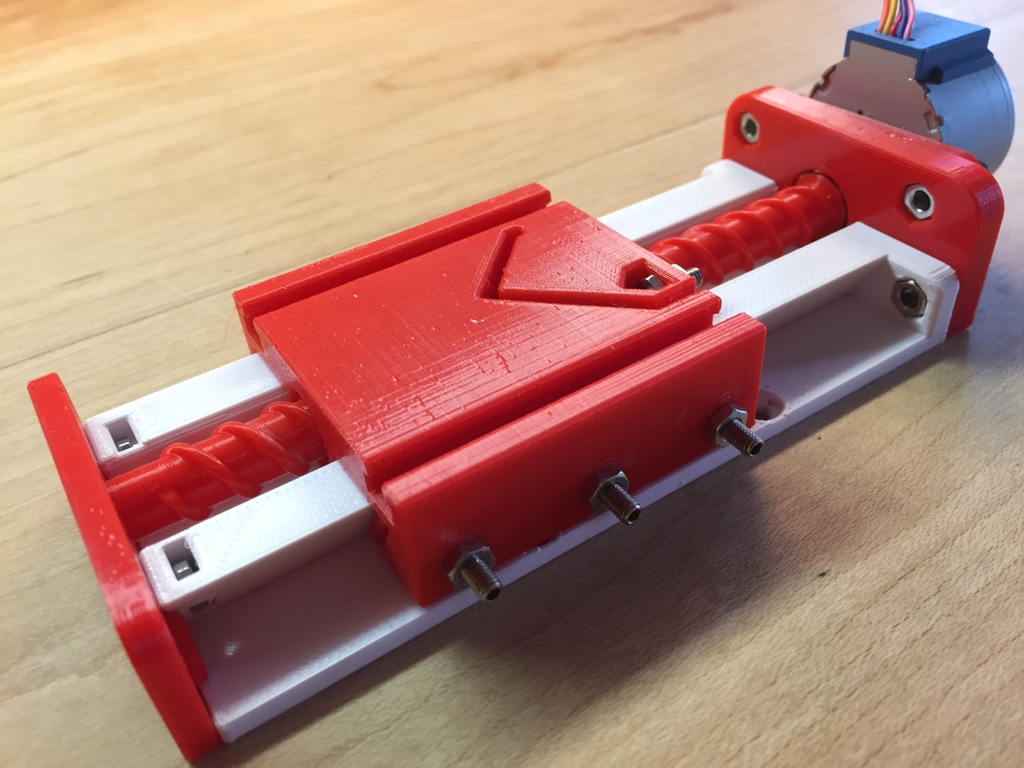

High Accuracy Dovetail Stepper Slide

thingiverse

##28BYJ-48 Mechanical Actuator #3 I thought it would be cool to see what kind of Mechanical Actuators we could make using the 28BYJ-48 stepper motor and mostly 3D printed parts. The 28BYJ-48 is a popular choice for Arduino kits, featuring a 5v dc motor with a max rpm of 15 and capable of around 4 oz force/in of torque. You can get these motors with the driver for around $2 each. ##Dovetail Stepper Slide This version builds upon the previous slide with two key changes: it's no longer directly driven, instead utilizing an integral bearing made from standard .177 (4.5mm) caliber steel BB's to handle thrust loads. This resolves issues of inaccuracy and play in internal gearing found in the original design. I've also added an anti-backlash feature to the threads on the carriage, allowing for adjustment to reduce backlash between the nut and drive screw. Tighten the anti-backlash set screw until it removes backlash but still rotates freely. If backlash isn't an issue, consider using the original slide requiring fewer parts. ==================================================================== Dovetail slides excel at accuracy, especially with a gib added to the dovetail way, allowing for adjustment of clearances between ways and carriage to reduce backlash. However, they're not ideal for long travels or fast speeds. This direct drive slide features a drive screw clamped directly to the shaft of the stepper motor, resulting in significant slop due to axial loads. The max RPM of the motor is 15, with a pitch of .5" on the drive screw, limiting max speed to 7.5" per minute. The motor can move roughly 7 lbs of weight on the carriage, but using grease on both the drive screw and way greatly increases load capacity and life cycle. The video showcases repeatability, demonstrating only .01" off location after running for a few hours. ==================================================================== ##Required Components - M3 Nut (14x) - M3 SHCS x 10mm lg. (4x) - M3 FHCS x 10mm lg. (2x) - M3 SHSS x 16mm lg. (3x) - M3 SHSS x 25mm lg. (1x) - .177 BB's (8x) - 28BYJ-48 Stepper Motor You can purchase a set of five stepper motors and drivers on Amazon through my affiliate link: https://amzn.to/2KJI6yz ##Assembly First, install the screw in the carriage and set the anti-backlash screw to the desired fit. Then remove the screw from the carriage and place it in the way with the gib key, using set screws to adjust for proper fit. Once fits are correct, build the screw into the bearing flange. ##Update 3/12/18 - I initially uploaded files with a triple lead screw instead of a double. The new file "DT-V3-SCREW-1_2-DBL.STL" features a double lead to match that on the carriage. Check out the video tutorials here: https://youtu.be/Yq39Y9Z1tzk and https://youtu.be/WCNtUWE9mQ0

With this file you will be able to print High Accuracy Dovetail Stepper Slide with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on High Accuracy Dovetail Stepper Slide .