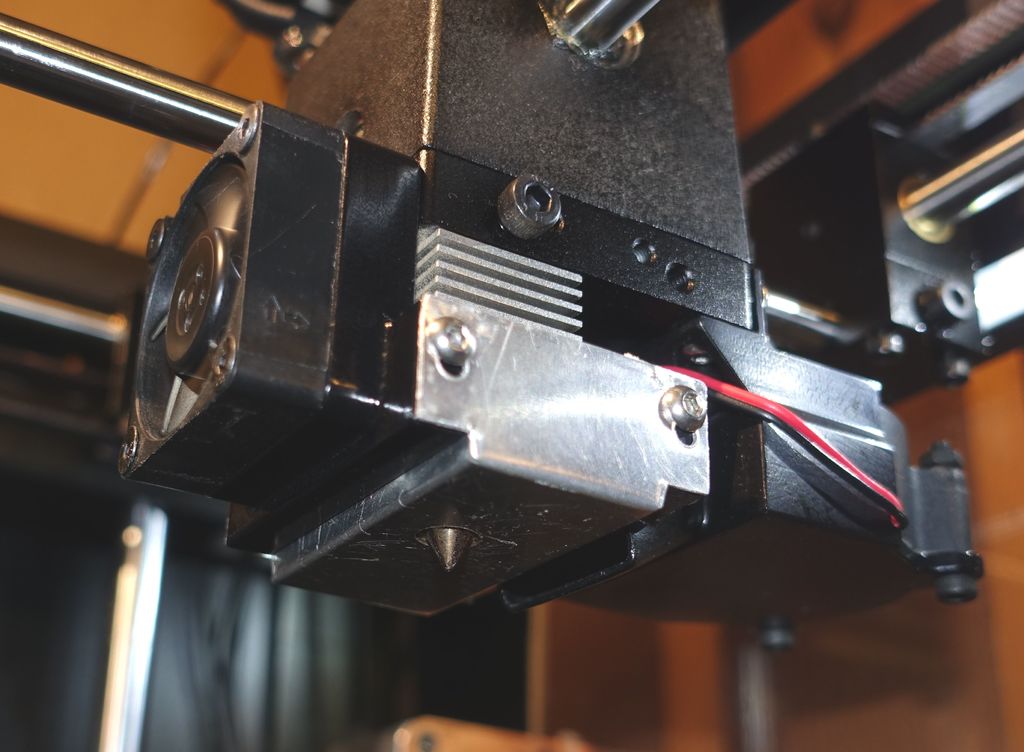

Hot-end insulation for Raise3D single extruder printers N1/N2/N2+.

thingiverse

This modification insulates the hot-end very effectively (3 x 1 mm ceramic fiber insulation on all sides of hot-end) and reduces the radiative heat transfer from the hot-end to the printed model. The power needed to heat the hot-end is significantly reduced and the fans ability to cool the cold side of the hot-end is much better, thereby reducing the risk of soft filament clogging in the PTFE pipe. The stronger model blower is very useful for printing PLA. The modification requires some metal sheet work. The 0.5 mm aluminium can be cut with a pair of scissors. You also need to cut many small pieces of Ceramic Fiber Insulation to size. The modification includes the following parts: - Duct for a 40 mm radial blower that gives a strong air flow around the nozzle tip. - Optimized duct for the standard 35 mm fan for the hot-end thermal barrier. - Heat-shield made from 0.5 mm aluminum, that also keeps thermal insulation material in place. Further materials needed: - 6 pcs. Heat-set M3 threaded brass inserts for Ø4 mm holes. - 7 pcs. M3 x 6 mm pan-head screws - 2 pcs. M3 x 20 mm cap-head or pan-head screws - 1 pcs. Renren3D Ball Bearing 12V Brushless Motor Blower 40x40x20 - Ceramic Fiber Insulation 1 mm thick - 0.5 mm Aluminum plate, semi hard The blower duct is not easy to print. Support must be used both from the build plate and internally in the model. As the duct has thin walls, I recommend using the dynamic extrusion width feature of Simplify3D rev. 4, although not strictly necessary. As the plastic is very close to the hot-end, the material must be ABS or PC. PLA will not stand the heat. After the modification, PID parameters and regulator open loop settings need to be changed in Marlin configuration.h file. If you don't know how to compile new Marlin firmware, then don't make this modification. Here are the new settings needed: - DEFAULT_Kp 14.0 - DEFAULT_Ki 0.2 - DEFAULT_Kd 200.0 - BANG_MAX 128 - PID_MAX 255 - PID_FUNCTIONAL_RANGE 30 These settings will result in almost no temperature overshoot when raising the temperature from e.g. 25 °C to 210 °C. With these settings, the regulator is almost insensible to starting and stopping filament extrusion and turning on and off the model cooling blower. The attached plot of the temperature settling curve includes starting and stopping filament extrusion and turning on and off the model cooling blower, after the temperature settled to 210 °C, but this is barely visible in the plot. In the second plot the temperature is raised to 260 °C and further to 300 °C. The settling times are very short.

With this file you will be able to print Hot-end insulation for Raise3D single extruder printers N1/N2/N2+. with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Hot-end insulation for Raise3D single extruder printers N1/N2/N2+..