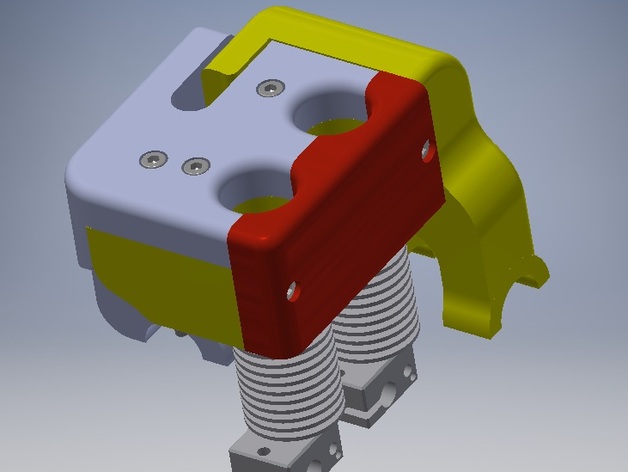

HOTEND MOUNT for Airwolf HD2x... Convert to E3D v6 NO Volcano - THIS IS FOR THE NON VOLCANO VERSION

thingiverse

This is a modification to Josh's original which may be found here with complete instructions on assembly.http://www.thingiverse.com/thing:956219 The short and sweet of it: if you want to take your Airwolf HD2x and print out something greater than 315C - then you need a different head assembly. If you want to go FAST get the E3DS V6 Volcano and use Josh's great STL files found on the link above, along with complete instructions. These files in this post are if you want to print in Hi Fidelity and at High Temperature, and also if you want to print with carbon containing material, Then get the E3DS V6 from the good folks at Filastruder :http://www.filastruder.com/products/all-metal-e3d-v6-hotend Be Sure that you read all of the instructions on Josh's post and note that my Bill of Materials is similar to his, but with the addition of one additional M3x45 socket head and M3 Hex nut. I wanted to put a leveling post on my version of this, like the original.. We may not need it, but why not put it in there? YOU WILL NEED: (2x) M3x20 Socket Head Cap Screw (3x) M3x45 Socket Head Cap Screw (5x) M3 Hex Nut (4x) Small zip ties (2x) E3D v6 + Hotness Like Josh said, proceed with caution as you will need to modify your software on this deal!http://wiki.e3d-online.com/wiki/E3D-v6_on_Airwolf_HDx_/_HD2x http://www.soliforum.com/topic/12034/upgrading-your-airwolf-hdx-hd2x-hotend-to-e3d-v6-volcano/ On8/20/16: If there are problems with your hot ends wiggling a bit with the original design and you don't want to shim it, i have uploaded a modified front piece which has taken the flats down by 0.5mm. Fixed the problem. Print Settings Printer Brand: Airwolf 3D Printer: AW3D HD Rafts: No Supports: Yes Resolution: .1 Infill: 80% Notes: I printed with PC-ABS with GREAT results. If you haven't printed with PC-ABS, then trust me, all your current frustrations will be gone once you make the leap from PLA and ABS. 80% infill may be overkill, but we are going for maximum strength here. I also did: .5mm nozzle 1.5mm walls and top and bottom speed of 65 Nozzle Temp: 300C Bed Temp: 140C For the support, find a setting that will support the insert hollow on the "back" part but does NOT support the inside of the holes that the zip ties go through. On Cura, that was 85 degrees for my printer, Grid at 20%, EVERYWHERE... If I went to 75 degrees it will fill the holes that the zip tie goes through... USE AIRWOLF's WOLFBITE MEGA for PC or PC/ABS. THIS STUFF IS AWESOME and prevents all the other issues with 3d printing. Magic stuff.

With this file you will be able to print HOTEND MOUNT for Airwolf HD2x... Convert to E3D v6 NO Volcano - THIS IS FOR THE NON VOLCANO VERSION with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on HOTEND MOUNT for Airwolf HD2x... Convert to E3D v6 NO Volcano - THIS IS FOR THE NON VOLCANO VERSION.