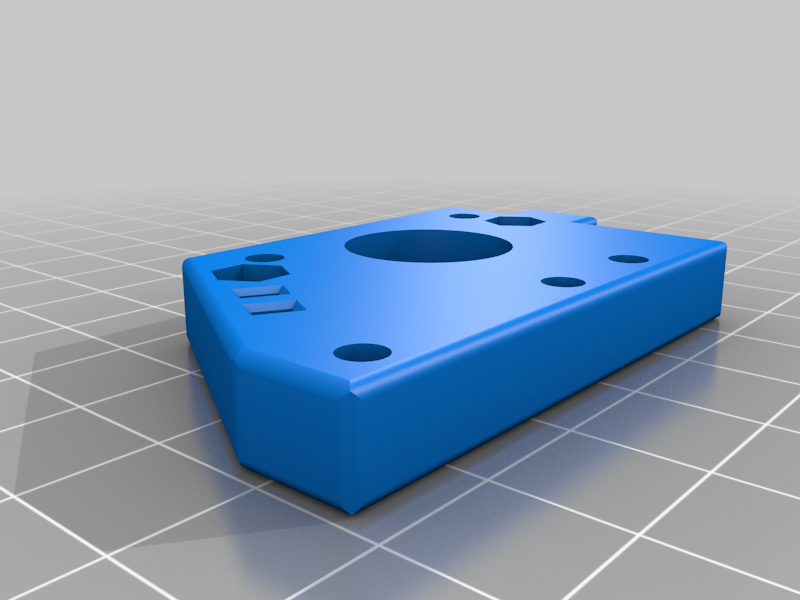

hydra duct orbiter extruder mount for ender 3/pro

thingiverse

***ALL OF THESE MODELS ARE DESIGNED WITH THE CREALITY STYLE HOTEND IN MIND (MICROSWISS, RED LIZARD V1, DRAGONFLY BMS, CREALITY ENDER/CR-10 STYLE ALL WORK). IT MAY WORK IN A V6 STYLE HOTEND, BUT THE BOWDEN TUBE MAY NOT LINE UP, IM NOT SURE AND I HAVE NOT TESTED IT*** if you have a v6 look at fredrikln 's "Hydra fan duct V6 edition Orbiter v1.5 adapter" [here](https://www.thingiverse.com/thing:4825929) Edit 8/19/2021: i have made 3 models for the ***orbiter v1.5*** **(if you have a v1 or v1 cr-10 Edit 3: 6/03/21)** - **FOR ALL VERSIONS OF THE ORBITER:** use all files of the original hydra except for the "head", here you will only need to replace the head (top plate). So select the proper fan size and left and right fan duct, and the proper side and rear duct base for your desired configuration). You will not need to select a "head" option from the hydra, and instead use one of the following, and be sure to ***print with hexagons facing up, 4 perimeters, 40%+ infill and no supports*** : - "right motor 6 degree- orbiter head for orbiter v1.5" - this is the model i recommend most users use. the reason for the 6 degree angle is to keep the bowden tube lined up with the hotend, and to avoid the existing mounting holes for the orbiter head, and to avoid colision with the 2040 z axis extrusion of the gantry (See edit 2 1/31/21 for details). *unless you have something mounted on the right of the x axis 2020 extrusion(such as a camera), if you have something on the right of the x axis 2020 extrusion use one of the following 2 options.* - "front motor 8 degree- orbiter head for orbiter v1.5" - this is not an optimal design since the majority of the weight of the motor, albeit a pretty light weight motor, will be further from the x axis 2020 causing more potential for ringing and a cantilevered design. however it will work if you have something on the right of the x axis 2020 extrusion. the reason for an 8 degree angle is to keep the bowden tube lined up with the hotend, and to avoid the existing mounting holes for the orbiter head. - "rear motor- orbiter head for orbiter v1.5" - this will likely not work for anyone, but @ awholenotherthing asked for me to model it regardless. the reason this should not work is because the motor sticks too far back and will collide with the 2040 z axis extrusions on the gantry. ________________ Edit 3: 6/03/21: sorry for all the iterations, but here is a breakdown: - **FOR ALL VERSIONS OF THE ORBITER:** use all files of the original hydra except for the "head", here you will only need to replace the head (top plate). So select the proper fan size and left and right fan duct, and the proper side and rear duct base for your desired configuration). You will not need to select a "head" option from the hydra, and instead use one of the following, and be sure to ***print with hexagons facing up, 4 perimeters, 40%+ infill and no supports*** : - for orbiter v1.0 cr-10 specific version use "orbiter head v4.5" (note: motor will be facing the rear of the printer) - for orbiter v1.0 (non-cr-10 aka the original) use "orbiter_head_v4.7_for_orbiter_v1.0_non_cr10_1.5mm_thicker.stl" (note: motor will be facing the right of the printer, slightly angled towards the front by 11.8°, this is done for clearance. See edit 2 1/31/21 for details) - for orbiter v1.5 @fredrikln made a remix. it says it's for the v6, but it might work, if it doesn't please let me know and I'll make one up link: https://www.thingiverse.com/thing:4825929 ______________________ **EVERYTHING BELOW IS IRRELEVENT INFORMATION** it is kept for a change log only ______________ edit 2: 1/31/21: apparently the 1mm closer on the non cr10 version was not enough. so, i turned this a total of 101.8 degrees (or 11.8 after the 90 degree rotation) this should keep the bowden tube near perfectly straight and allowed for the original screws to be mounted. i extended the head out further by about 10mm to accommodate the additional screw. i feel that this looks better and provides more structural support than having an arm reach out like i did on the right side of the original design. edit 1/31/21: the orbiter head v4.5 was messed up, but i fixed it and re-uploaded it under the same name. there was a compatibility issue with the non cr10 version. i have made a new file that is 1.5mm thicker but moves the mount for the orbiter 1mm forward. this is the "orbiter head v4.6 for orbiter v1.0 non_cr10_1.5mm_thicker.stl" edit 1/30/21: I believe there was an issue with my cad file alignment with the hotend since even for me and the cr10 version of the orbiter my Bowden tube is at a slight angle http://imgur.com/a/RJhIrBO i have thus moved the orbiter extruder 1mm to the left to make this more straight. i have not printed this for myself, but there should be no issues. this file is the orbiter head v4.5 i have also created a file for the original non-cr-10 version of the orbiter. this should align with a stock cr-10/ender3 style hotend. EDIT:1-1-21 after i posted this and i realized the limitations of compatibility, i realized i could design a different head mount that would be compatible with all versions of the hydra (since all hydra variations use the same head mounting holes.) this increases the thickness of the head by 1mm and allows for 4mm thick m3 nylock nuts. i would say that my older version allows for better stability, but im sure this will be practically just as good. the file will be "orbiter head v4". NO SUPPORTS NEEDED FOR THIS PART IF YOU PRINT WITH THE HEX HOLES FACING UP. i have a sacrificial layer designed to not need supports for this part _________________ original post: this will only work with the cr10 variant of the orbiter https://www.thingiverse.com/thing:4609940 i edited the left and right sides of the duct in tinkercad to allow for the 2 screws needed for the oribiter extruder. and redesigned the head to be compatiable with the new holes and offer more stability for the extruder. this design is for the ender 3 and ender 3 pro. due to the design you may not be able to use this on other creality machines, but i cant confirm. printed with 4 perimeters and petg 40% infil, supports as needed.

With this file you will be able to print hydra duct orbiter extruder mount for ender 3/pro with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on hydra duct orbiter extruder mount for ender 3/pro.