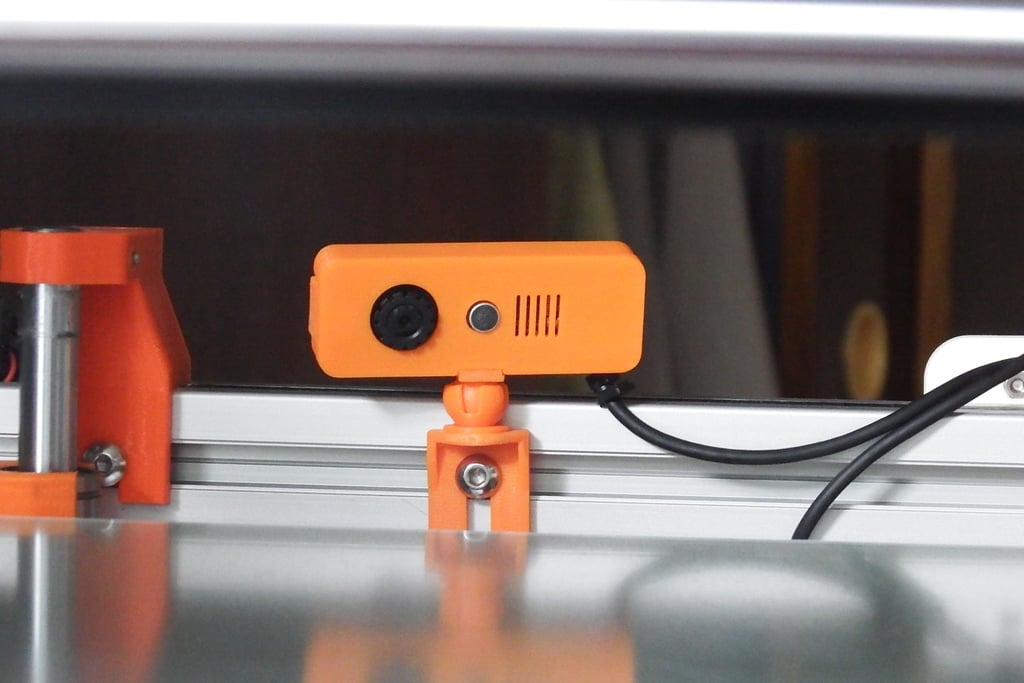

HyperCube Evolution: Logitech c270 webcam mount

thingiverse

To control the printing process running Octoprint, I use a Logitech c270 webcam. I saw a beautiful small-sized case developed by Pomaser ("Logitech C270 Webcam Cover Replacement (with GoPro Mount)", https://www.thingiverse.com/thing:3748407) and decided to use it instead of the original one. <p></p> <p></p> <h1>Design idea</h1> The GoPro mount for installing the camera on the printer did not suit me, I had to develop my own. My ball joint is universal, and you can print it separately and use it in any of your designs.. The bracket is designed for fastening with an M5 screw on a machine profile 30x30. The platform is intentionally made longer than 30mm, so that it is possible to install it higher. And if this is not necessary, shortening is easier than lengthening. The development is done in SolidWorks, the files are attached - you can make your own modification (by increasing or decreasing the diameter of the joint sphere). <p></p> <p></p> <h1>Remixed parts</h1> The case is modified in the NetFabb editor - the mount for GoPro is cut off. The front panel is left original, please take the "C270CameraCover.STL" file from the project https://www.thingiverse.com/thing:3748407 by Pomaser. I can note the excellent compatibility of the parts he developed after printing. The case was printed from PLA, 0.2mm thick. On narrow plates (housing latches and USB cable clamp), the layer thickness was reduced to 0.1mm and the speed was reduced to 30mm/s. <p></p> <p></p> <h1>Production and Printing</h1> All the parts I designed are printed out of PLA plastic and glued with cyacrine. <p></p> <p></p> I advise printing the ball joint parts (especially its spherical elements) in layers no thicker than 0.2mm (better - 0.16mm or even 0.1mm) and with sufficient cooling - then support is not required. If the joint turns out to be too tight, you can gently smooth the layers on the surface of the ball with a flat file. <p></p> <p></p> <h1>Using multiple brackets for a single camera</h1> You can print several brackets with the outer part of the joint, and install them in different places on the printer frame. Depending on the purpose of shooting (technical control of printing, time-lapse feature film, etc.), you can easily rearrange the camera from one bracket to another and change the shooting point.

With this file you will be able to print HyperCube Evolution: Logitech c270 webcam mount with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on HyperCube Evolution: Logitech c270 webcam mount.