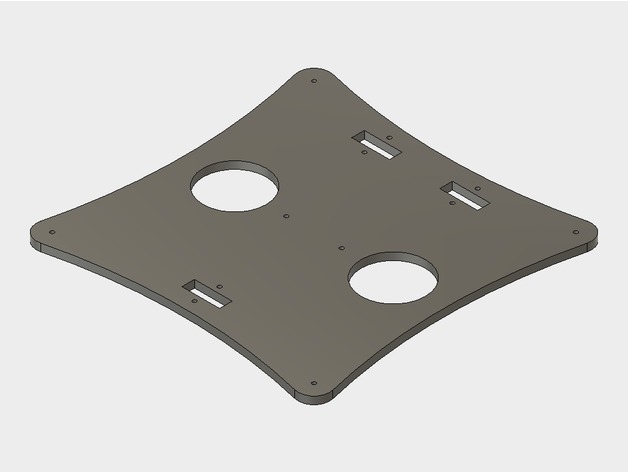

Improved Prusa / Cartesian Printer Heated Bed Support - Redesigned for Wood

thingiverse

IMPROVED TEMPLATE for Prusa i3 / Cartesian Heated Bed Support Plate. The Y-Axis bed is the most overlooked yet one of the most crucial parts of your Cartesian 3d printer, and being the first part constructed, often gets little attention later. The existing plate was obviously designed to be laser cut, where most hobbyists cut them using hand tools or whatever power tools they have to hand, and cut from aluminium or acrylic, the former an excellent heatsink material that wicks away the heat from your heated bed increasing bed heating times (not ideal!) and the latter stiffer than most materials meaning the thin arms, worse than those of a T-Rex, spring around like a mad jack-in-a-box if not damped. If it is good thermal properties and strength you're after, then you can usually opt for a low-cost nano-material with excellent low thermal conductivity, high strength to weight ratios due to a compact and pseudo-random carbon nano-structure, one readily available nearly everywhere... namely this material called 'wood'. The sharply cut corners of the traditional frame also direct stress to those vulnerable sharp corners, with a tiny saving in weight. Drilling those corners to automatically fillet them could easily have been incorporated into the design for hand-tool or drill stand users. Added to this, users might like to choose between stronger but more fiddly to get right, 4 linear bearings or the more traditionally and actually more triangularly stable, 3 linear bearing supports on the bed frame. Wood, usually plywood, using the existing template ends up being springy where you don't want it to be springy and insufficiently rigid due to the thin arms. Additionally, most folks today DON'T use manual bed-leveling either, which is another issue. This template was designed to be cut from wood, using only a 3mm drill for all the holes and for starting ANY of the cutouts, as a corner fillet, namely requiring minimal tooling and marks out the centres of those holes for drilling. A recent issue regarding SAFETY of electrically heated aluminium plate beds where metal screws and springs can cut into the heated bed and cause ELECTRICAL SHORTS and potential safety issues can be addressed by using NYLON M3 BOLTS, WASHERS, NUTS and FIXED STANDOFFS in lieu of springs to hold the heated bed to this plate. My heated bed is a MK3 BLACK aluminium plate type. FIXING the bed height using standoffs rather than springs will also take out the oscillation of the bed on its manual adjustment springs (causing them to cut into the heated bed material perhaps leading to a short!) when the bed accelerates or decelerates in the Y axis. These are not strictly necessary anyhow if you have auto-bed-leveling via an inductive sensor. If you're getting layer alignment problems at the ends of any y axis acceleration, these springs are likely the cause. I intend to use nylon fittings, as described, to secure the heated bed to this plate, but you should choose what option is best for you. The template is PARAMETRIC and all the major measurements can be changed as per your custom-setup, although the default measurements are the defaults as measured directly from my home-made clone. NOTE. You do NOT need to cut out ALL SIX (6) linear bearing slots and holes. Cut those you need. Included are TWO Body options (images shown above) in the Fusion360 file, namely, one for THREE (3) linear bearings (RJ-4JP-01-08 or LM8UU bearings) and one for FOUR (4) such bearings, as per your pleasure. The plate is symmetrical, easing manufacture. NOTE. The only non-standard measurement seems to be the bolt hole separation on the 3d printed Belt Gripping Block in the centre of the plate, as I have seen three different separations. If yours is NOT 44mm then you'll have to modify this but the design will automatically adjust, as per Fusion360... or you can just put your holes in the right places along the SAME centre line. I hope this template is of use to you and the hardware requirements are listed in the Fusion360 file, on the 'Modify' -> 'Change Parameters' page. It has a nice organic shape and 'should be' a drop in replacement for your existing heated bed support. Please let me know if it isn't. This is my first project on Thingiverse. Feel free to comment. I'm somewhat new to this... Post-Printing File rough edges smooth as approprate. If hand cut using hand tools then sand and/or file as appropriate. How I Designed This Designed using Fusion 360 as a One Hour Design. Took time from designing a new drone to measure my existing bed and draw the template of the improvements I have had in mind for ages.... but due to laziness haven't gotten round to. Custom Section Materials Required 1 x Sheet of Wood - Minimum 235mm x 235mm x 6mm Optional... 4 x M3 NYLON Bolt L20mm 4 x M3 NYLON Nut 8 x M3 NYLON Washer 4 x M3 NYLON StandOff L10mm As safety replacements for attaching your heated bed to this support plate. I used two pieces of 3mm HARDBOARD, sanded the SHINY SURFACE, cuz that's the way I roll, and glued them together using TWO PART EPOXY, sanded-shiny surfaces glued together, to give a matt rough appearance.Clamped tightly and left to cure overnight. Print out the template at 100% and glue stick it onto the wood on the side that will be the underside, then grab hand-tools and liberally apply yourself all over the wood OR, if you're one of those people with a workshop, cut using expensive tools. Hardboard rescued from an old door; Cost zero. Two-Part Epoxy; Cost £1 from a 'pound shop', included ONE decent clamp and spreader, used the packaging the epoxy came in to mix the two parts together. Additional tools required; Hands, Drill + 3mm drill, Saw, Sandpaper. Mine weighs approx 300g, is roughly 6mm thick and is as rigid as stainless steel. Hope this helps.

With this file you will be able to print Improved Prusa / Cartesian Printer Heated Bed Support - Redesigned for Wood with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Improved Prusa / Cartesian Printer Heated Bed Support - Redesigned for Wood.