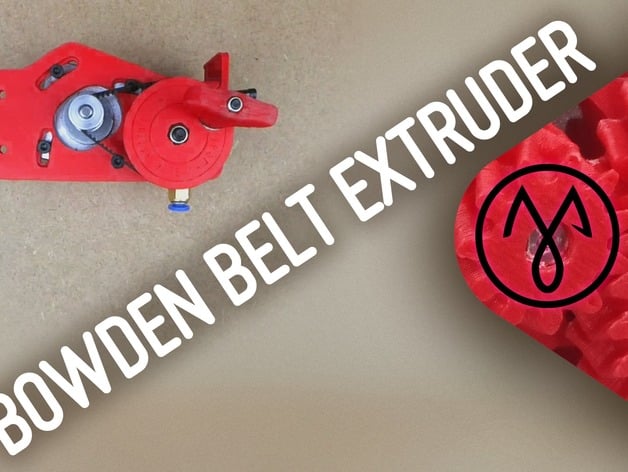

J-Max_Bowden Belt Extruder (feeder) V1.0

thingiverse

French version : http://www.j-max.fr/?p=632 English : Fade up about plastic gears noise, let me introduce you to my Bowden Belt Extruder v1.0. It's quiet and effective with a 4:1 reduction ratio. This is a compact feeder compared to RichRap's. The belt tensioning is assumed by a radial insert of the motor. The unibody feeder is very stiff for enhanced extrusion precision. We added a crank to the secondary pulley to allow to feed/unfeed the filament quick and easy. The lock inspired from the lulzbot Taz5 one allows a quick release in no time to access to the hobbed gear easily for maintenance, through, because the tight fit of the filament guidance you don't realy need to open the idler to insert a new filament. See video for further presentation : https://youtu.be/mSWpEaICI2o Or for assembly instructions : https://youtu.be/LU_pFnTfH9M The extrudeur was in beta mode during 6 months and had 4 beta testers (thanks to my friends at the KB group ;) ) Several versions of the parts leaded to that V1.0 extruder that we don't have actualy nothing to complain about. Actualy, I don't think it's necessary to develop any 3mm extruder, as it will soon RIP (here in europe, the shops are doing sales on that diameter). Add-ons There is different body versions. Big thanks to Rexipus for his version of the body part to be mounted on horizontal rails OpenBuilds 2020 profiles (please note a little file job may be required, and this version does not fit for 2020 module 6 or 5mm, use original mounting holes instead.). You can print the body part reversed, as Rexipus did, for more comfort or to mount two extruders side by side. Huge Thanks to Denis (digiTALker) who have worked on an 200mm belt body version. Big thanks To Phil (sysimgrp) who designed interesting parts : a longer crank extension for more comfort if you have enough space and a great clamp head which uses no springs. Many thanks to the maker's community to help making this small idea at the start of a bowden belt extruder to become a much versatile extruder with extra parts options to fit a large field of uses. You guys are awesome ! BOM : Hardware : 1x Nema17 motor (any kind at last 34mm long) 1x GT2 2mm 80 tooth closed loop belt 1x GT2 2mm 16 tooth regular pulley 4x DIN912 M3x8mm screws (for motor mount) 1x DIN912 M3x20mm Screw (for idler's bearing mount) 1x DIN912 M3x25mm Screw (for idler mount) 1x DIN912 M3x30mm Screw (for crank mount) 2x DIN912 M3x40mm Screws (for the lock system) AND add a M3x30mm if you choose Phil's springless lock. 1x DIN912 M5x40mm Screw (for the hobbed gear/secondary pulley axis) /!\ File a flat side for the MK7 Screw OR M5x50mm if you choose Phil's Extanded Crank. 5x DIN985 M3 Nylstop nuts (for M3 screws except obviously 8mm ones) 1x DIN985 M5 Nylstop nut (for the secondary pulley fixing) 1x M3 washer (any kind will fit, even if we use Nylon ones - used for the crank) 2x DIN127 M5 grover washer (for the hobbed gear/secondary pulley axis) 1x M5 washer (any kind will fit - used for the secondary pulley alignment) 1x 623 bearing (for idler bearing) 2x MF105 bearing (for the hobbed gear/secondary pulley axis) 2x 4x20mm springs (actualy we use recycled pencil ones - used for the lock system) 1x 3/8" 4mm push in fitting (for bowden 4mm teflon tube) 1x MK7 Hobbed gear (better than the MK8 IMHO) /!\ Pay attention to buy a proper MK7 hobbed gear for 1.75mm filaments. The universal MK7 for both 1.75 and 3mm filament may not suit perfectly. The perfect dimensions are : 5mm bore ; 11mm tall ; 12mm (or 1/2") in diameter ; a 3mm wide hobbed groove centered at 3mm from the top, with an inner diameter of the grove of 11mm (10.5mm is still acceptable). Some cheap MK7 measures 12mm in height but you still can file or grind it a few to make it suit. Pastic printed parts : 1x Feeder body 1x GT2 64 tooth secondary pulley 1x Crank for secondary pulley 1x Idler 1x Lock Necessary tools : 1.4mm Allen Hex key (for hobbed gear and GT2 16T pulley) 2.5mm Allen Hex key (for M3 screws) 4mm Allen Hex key (for M5 screw) 5.5mm wrench for M3 nuts 8mm wrench for M5 nuts 9.5mm wrench for pneufit thin plyers (for deburing) utility knife (for deburing) 3mm bit (for deburing) 5mm bit (for deburing) a gas lighter (for deburing stringing) See video for deburing and mounting details. Note it could be useful to make a small nocht with a file on the M5x40 shaft. This will help the MK7 screw to hold in place. I wrote the story of that extruder on : https://www.instructables.com/id/Bowden-Belt-Extruder/ /!\ the part named "J-Max_BowdenBeltExtruder_Body2020OpenBuildsByRexipus.stl" is mirrored. If you chose this model, you must print both the idler and clamp par mirored to match this body part. Print Settings Printer Brand: RepRap Printer: Prusa I3, CoreXY Rafts: No Supports: Yes Resolution: at last 0.3mm 2mm layers Infill: at last 50% Notes: Please set "supports everywhere", and prefer strong filaments : ABS, PETG, Carbon fibre reinforced PETG, POM, PC. Note, this is a compact feeder, a high infill level in relationship with your filament type is necessary to prevent any twist during operation. Post-Printing What to do, just out of the build plate. Deburring operation :

With this file you will be able to print J-Max_Bowden Belt Extruder (feeder) V1.0 with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on J-Max_Bowden Belt Extruder (feeder) V1.0.