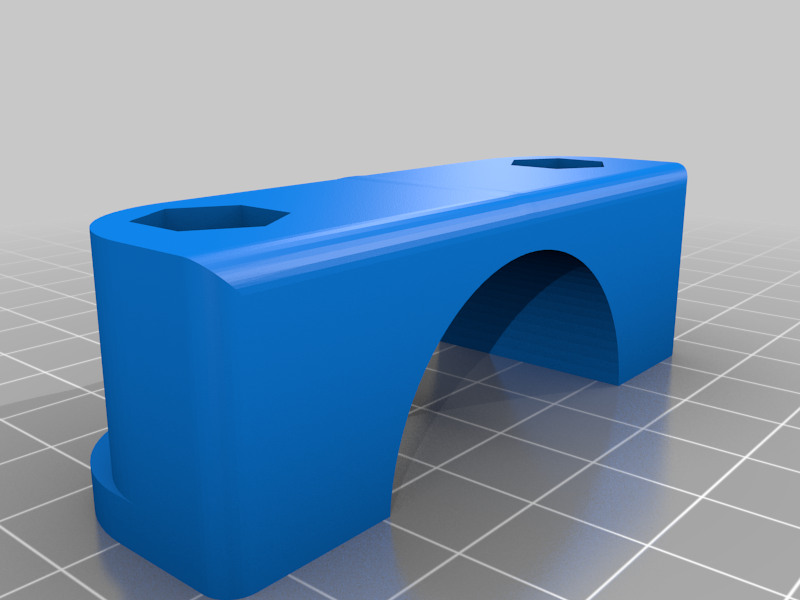

Jaspers clamp

thingiverse

Print settings: For PLA, use AT LEAST 0.10mm layer height, 80% or more infill. That said, PLA is really too stiff for this application. PLA @60%+0.15mm layer height does not "grab" well enough to be stable for almost any reasonable load. The shelf in the photos is only using 1 clamp, but even with two, I was still able to move the shelf after tightening it down. PETG or ABS would be better. OEM clamps are glass fiber reinforced ABS. Less than 80% infill may result in nuts rounding out the inside of the fitted holes and making things VERY difficult to disassemble. Do NOT use nylon lock nuts! They will put FAR too much strain on the fitted holes even with 80% infill. You have been warned! Print with the "flattest" side down. This will let the printer do it's best curve along the inside diameter where it clamps to the tube. This will provide the most uniform surface area and reduce the potential for gouging into the aluminum when tightened. Earlier revisions had a symmetrical design but removing the support material was a pain and when you have to print at least 4... I'm sure the design could be optimized further, but I figured this is good enough to get it out there. Hardware suggestions: M6-1.0 x 50mm bolts will protrude about 10.3mm on the threaded side. (I used these https://www.amazon.com/gp/product/B07D9Q24FH/) I don't have shorter bolts to test with but I assume 40mm bolts would protrude about 0.3mm and 35mm bolts would be able to fully thread and not protrude at all. Again, I HIGHLY suggest using normal, non-locking nuts. I combined these with some sawn boards to hold additional gear. *_Keep in mind that these will very likely void your 5 year warranty from Jaspers._* > The warranty does not cover defects which are caused by the use of accessories, components or replacement parts which are not original components. It's your decision to trust these to hold your expensive equipment. :) Potential future modifications, if I ever get around to it (or suggestions for others) - Integrated zip tie slot - Extended bolt carriers to allow mounting things with non-M6 sized bolts - Additional bolt holes for extruded aluminum sliding nut fittings - Camera or Microphone insert - Instrument holder (Akai EWI USB is on my list) - Eurorack cheeks Comment with more suggestions and maybe I'll get around to hacking it out.

With this file you will be able to print Jaspers clamp with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Jaspers clamp.