JD Groove Mount Plate

thingiverse

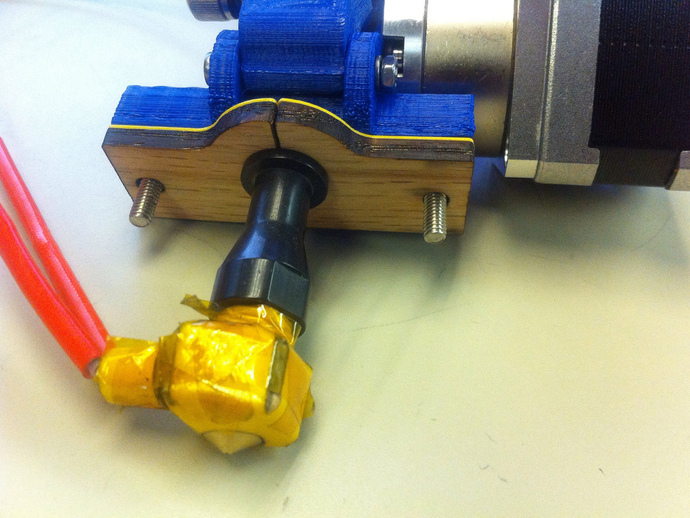

I couldn't find a groove mount plate that supported the barrel groove all the way around the groove, top and bottom so I designed one that does much better at that. If the plate thickness is tailored to the groove correctly, it securely holds the barrel in slight compression. The groove might vary between hot ends, so that's why I have cut a pair of shim pieces too, shown in yellow in the pictures. New for V2 - interlocking shim stock plates. I made the "core" structure with the parts on the right, the parts on the left were made from plastic shim stock to precisely tighten around the groove without damaging the barrel or the mount plate. Instructions I think this fits most common open source RepRap extruder designs, but it is up to the user to determine the fitness of this part design for their project. All files should be the same geometry in different file formats, drawn 1 unit = 1mm. This drawing is kerf-compensated for approximately 0.125mm kerf. Ideally, this would be cut from material that matches or very slightly exceeds the height of the groove on your barrel, but you may need to find more than one piece. For the wood piece, I cut from a small plank of solid red oak. The yellow piece is plastic shim tock. I think the mount plates should hold themselves in, at least a little bit. once the extruder is bolted down, this should be a very secure mount, more secure than groove mounts that are a slot, which about 40% of the barrel isn't supported. Users of extruders that use 3mm bolt holes may want to change the hole size to 3mm for some extruders, the extruder I chose to make this time used 4mm bolts.

With this file you will be able to print JD Groove Mount Plate with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on JD Groove Mount Plate.