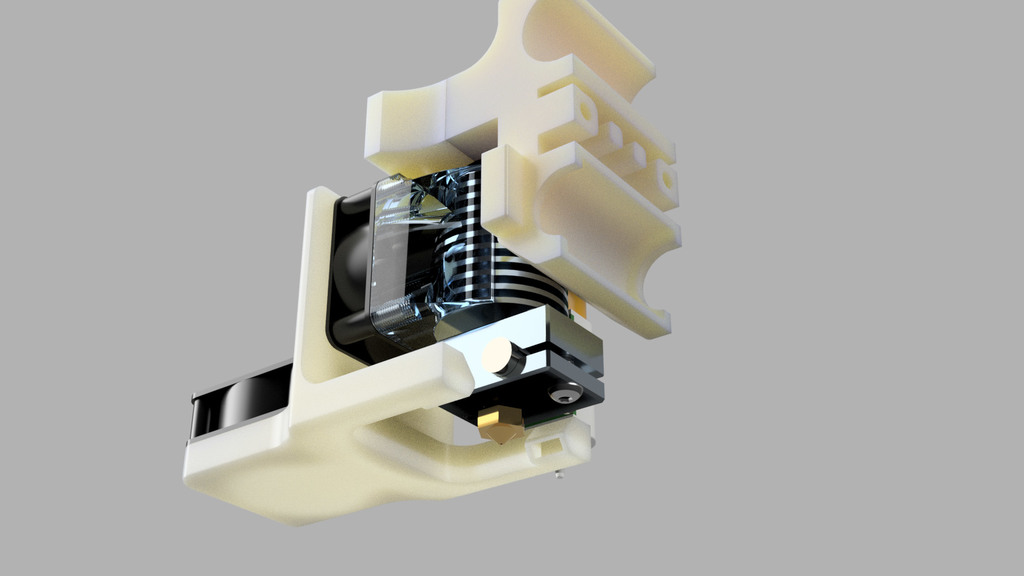

JGAurora A5 E3D V6 conversion – 30 mm fans

thingiverse

*Revision 3.1 update* Added Klipper config file if you are going to use it instead of Marlin (and I will!). Original MKS Gen L v1.0 8 bit board on JGAurora A5 is too slow for features like Linear/Pressure advance, Klipper works great. Adjust your settings as required (ie. use different thermistor than I have preset – Trianglelabs T-D500) if using stock thermistor *Revision 3.0 update* Added configuration files for Marlin 2.0.7.2. These configs are set for BLTouch, K-D500 thermistor from Trianglelabs (you have to make your own PID tuning!) and have all prerequisities for bed size, margins for bed leveling etc. Please modify configuration if you are going to use another type of thermistor. Bed leveling type: Bilinear (ABL), 7x7 grid – change this too to lower value if it seems slow to you. Also set DEFAULT_AXIS_STEPS_PER_UNIT, mine is set for BMG type extruder (dual drive gear) so value of 419.68 is very high for regular extruder (stock is about 133) Linear Advance 1.5 is activated too, so tune it for your filament and enjoy much better quality, less blobbing and stringing too! *Revision 2.0 update* I have added file ***05. Heatsink fan adapter*** to change airflow of main (always on) fan to vertical. I have discovered (or maybe it's a placebo) that two fans at 90 ° angle fights (or so I presume) for airflow and thus, layer cooling fan doesn't provide too much airflow to cool layer sufficiently and quickly. If you experience such problem, please print this file and attach it to the top of the main fan duct (render #4) #This is an E3D V6 hotend mount for JGAurora A5. From the others it's quite different. It uses original (or better, new, silent) 30 mm/24 V fans instead of big 40 mm 12 V fans. It has few advantages: 1.) Most notably, it's a lot smaller mount and less heavy 2.) You don't need any voltage changers 3.) Quality 30 mm fans provide much better cooling than 40 mm Noctuas typically used (and I like Noctua fans!) **What you need** 1. E3D hotend or a clone (duh!). Trianglelabs makes nice ones, even great bi-metal heatbreak 2. M3 screws, flat head – 20 mm long, 14 mm long, 12 mm long 3. M3 thread inserts, 4 mm long (L4) – I suggest this type. https://www.aliexpress.com/item/4000909684199.html?spm=a2g0s.9042311.0.0.27424c4dOWz6jJ Also 2 M3 nuts (to join X carriage with original front X carriage part together) 4. M2.5 thread inserts (for X stop switch) 5. Ideally, replace original 24 V fans with brushless, two ball, much more powerful and SILENT ones from here: https://www.aliexpress.com/item/4000256787938.html?spm=a2g0s.9042311.0.0.27424c4dOWz6jJ (Choose type 0.06A3010B24V2P2.54) – you will need to re-solder the connector. **Note** Some images shows older version of BLTouch mount. That has been updated and moved 4.5 mm closer toward the display (front) as original version was hitting frame and thus, bed size in X axis would be smaller. **Printing, material etc.** For a X carriage and fan duct I contacted professional printing service and asked them to print it from Ultem 1010 (or PEI). This is a high grade, high temperature engineering material that can sustain temps up to 217 °C (Tg) – popular in medical and aeronautics industries. Maybe it's an overkill, but I wanted to have peace of mind when it's nearby the heat block. You can use ABS (I printed BLTouch mount and E3D Clamps from Z-Ultrat, which is basically ABS). **Last but not least** I suggest to upgrade to Marlin 2.0, especially if you are going to use original BLTouch 3.1. While you are at it and going to use all metal (or titanium or bi-metal) heatbreak, upgrade max temps up to 300 °C or even change thermistor for new K-D500 thermistor or PT-100 and you can go even higher (but use copper heat block, as alluminium can withstand only 300 °C max). DO NOT forget to change retractions to smaller values in your slicer (max 2 mm should be enough, I'm using 1.5 mm for PLA and it works fine, retract. speed 45 – 60 mm/s or 35 mm/s for BMG type). Higher retractions only for PETG, PLA will otherwise clog (don't ask me how I know). **BED SIZE – IMPORTANT!!!** X – 295 mm Y – 285 mm (so you will lose about 15 - 20 mm as nozzle is furher from front) **Z probe offsets in Marlin** (approx.) X: 27 mm Y: 2.5 mm Z: -1.9 mm (set this via M851 command as this highly depends on your manual bed leveling)

With this file you will be able to print JGAurora A5 E3D V6 conversion – 30 mm fans with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on JGAurora A5 E3D V6 conversion – 30 mm fans.