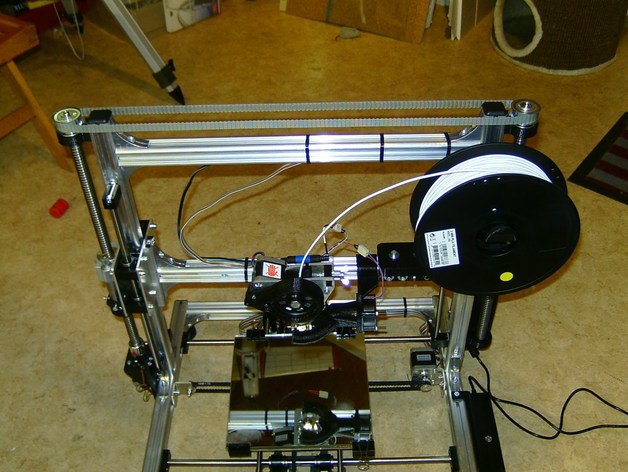

K8200 / 3Drag double z-axis spindle TR16x4

thingiverse

This is a double z-axis modification for the K8200 or 3Drag printer to eliminate the wobbling once for all. It's based on two TR16x4 trapezoid spindles - which make it very solid but also stable and precise. Instructions Parts you'll need to make this (see references for my sources of supply): 2x right-handed TR16x4 trapezoid spindles 400mm length, ready to build-in [1] 2x right-handed spindle nuts for TR16x4 [2] 3x ball bearings 6200 (10x30x9) [3] 1x flexible shaft coupling 5mm to 10 mm [4] 1x tooth belt T5 10mm x 1215mm [5] 2 pulleys T5, 20 teeth [6] 1x snap-ring 10mm [7] some screws (you can recycle some of the old z-axis screws) Instructions: The pulleys are sold undrilled. You will need to do this yourself. Use a drill press or lathe for this. Drill diameter: 10mm in the lower half; 8mm in the upper half. You should also add a set screw to fix the pulleys. To be absolutely sure the pulleys won't slip off, you can drill a 3.3 mm hole in the top of the spindle, cut a thread for 4mm screws and fix the pulley with a screw as shown in the images. The right spindle is secured by a snap-ring at its bottom (wear eye-protection when you mount the snap-ring!) Since the spindle will be a little bit more away from the printer frame, you will need a new z-motor holder (Z-motor_mount.stl and Z-motor_panel.stl). I'm using a micrometer device to adjust the z-height. If you want this too, you need to print the parts micrometer_mount.stl and Z-switch_mount.stl The original spool holder cannot be used anymore. I've made an alternative spool holder which can be used instead (spool_holder.stl) The new z-resolution must be configured in Repetier Host: 3200 / 4 = 800 steps per mm (see screen shot). Notes: The right ball bearing holder needs to be printed twice. It's ok if the tooth belt is not very tautly. If you however think it is too floppy, you can stretch it with washers on the right ball bearing holders. This modification reduces the z-resolution by the factor 4. However this is still good enough (800 steps per 1 mm height => 0.00125 mm per step) and furthermore all typical layer heights (0.1, 0.15, 0.20, etc.) are possible without any rounding errors. The design files are included and can be opened with DesignSpark Mechanical - feel free to modify this thing at will... References: [1] http://www.dold-mechatronik.de/Trapezgewindespindel-TR-16X4-rechts-einbaufertig-Nennlaenge-400mm- [2] http://www.dold-mechatronik.de/Trapezgewindemutter-16x4-R-Rotguss-mit-Aluminiumgehaeuse [3] http://www.dold-mechatronik.de/Rillenkugellager-6200-2RS-10x30x9mm- [4] http://www.dold-mechatronik.de/Wellenkupplung-XB-flexibel-D25L30-500/1000mm- [5] https://www.maedler.de/Article/16266200 [6] https://www.maedler.de/Article/16222000 [7] https://www.maedler.de/Article/61741000

With this file you will be able to print K8200 / 3Drag double z-axis spindle TR16x4 with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on K8200 / 3Drag double z-axis spindle TR16x4.