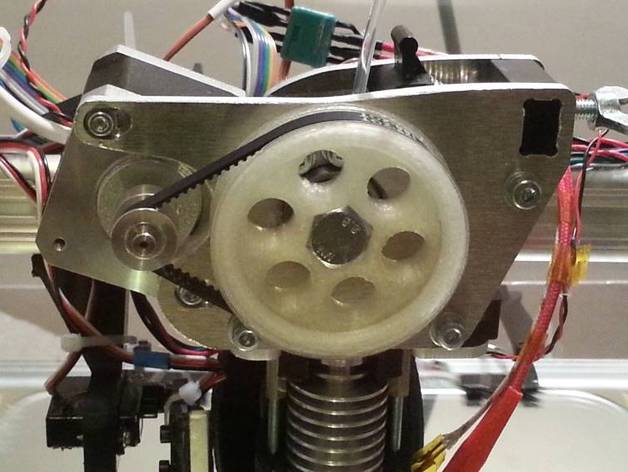

K8200 / 3drag GT2 belt extruder

thingiverse

A simple way to change to belt extrusion for less noise and reduced wear. Includes a printable 80 tooth GT2 pulley. openSCAD parametric cad file included. Can be used to change number of teeth. Based on this very nice pulleys library:http://www.thingiverse.com/thing:16627 UPDATE: There was a version posted with no holes and a thin back wall. It didn't work well since it flexed too much. It has now been removed. Thanks to turbotommi for testing. UPDATE 14/01: RobotDigg changed the GT2 belt pack. See instructions for details Print Settings Printer: K8200 very modified Rafts: No Supports: No Resolution: 0.3mm layers Infill: 25% Notes: PLA or ABS. Nylon is too flexible. Invert to print without support Print outer perimeters slowly for best tooth resolution (~40mm/s). Infill as fast as you like. Instructions The 80 tooth pulley included puts the motor at maximum adjustment. You may wish to print an 82tooth version or use a 20tooth pulley on the motor side. My preference is for more torque to prevent the extruder stalling. openSCAD compilation, STL generation and slicing is quite slow due to the high definition teeth and cutout details. WARNING: The belt changes the direction of the extrude motor compared to gears. You will need to rebuild and reprogram for this to work. See this code line in configuration.h: https://github.com/MarlinFirmware/Marlin/blob/Release/Marlin/Configuration.h#L323 The line number changes as the codebase changes. You may need to search for E0_DIR to find it. The K8200 code has it set true. It should be set to false as follows: "#define INVERT E0_DIR false" The ratio is 16:80 instead of 10:44 so you need to change steps/mm from 600 to 682. This is set in the eeprom settings through repetier. The default values are set in configuration.h here as defined value DEFAULT_AXIS_STEPS_PER_UNIT. Extrude step ratio is the last value in the set:https://github.com/MarlinFirmware/Marlin/blob/Release/Marlin/Configuration.h#L482 This value is overidden by the EEPROM contents. If you change the default you may not get any real change. Modify using repetier eeprom settings. Using these parts from robotdigg allows the belt to be tight enough at the end of the motor adjustment range: 16tooth 5mm bore GT2 pulleyhttp://www.robotdigg.com/product/59/Rostock-16-Teeth-5mm-Bore-GT2-Pulley 188mm GT2 belt : UPDATED 14/01http://www.robotdigg.com/product/280/180mm,-186mm-or-188mm,-6mm-width,-Closed-loop,-GT2-belt If this belt is not in stock, turbotommi found GT2 belt at aliexpress:http://de.aliexpress.com/item/10pcs-lot-188-2GT-6-GT2-timing-belts-94-teeth-Length-188mm-width-6mm-in-closed/1837021682.html

With this file you will be able to print K8200 / 3drag GT2 belt extruder with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on K8200 / 3drag GT2 belt extruder.