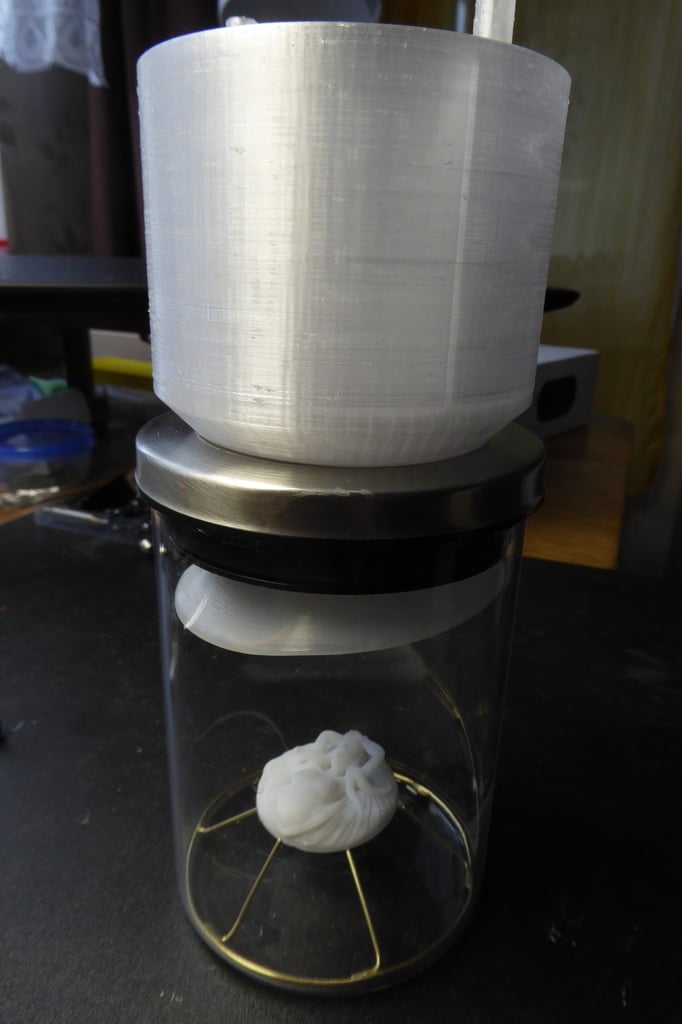

Setup for HIPS smoothing in hot vapours

thingiverse

WARNING: This process can be dangerous if you are a moron. Don't drink xylene. You will die if you drink enough. Don't heat solvents by an open flame. The vapours will ignite. This is a setup to process printed parts is hot vapours, specifically to smooth HIPS part in the xylene vapour. Two solvents can be used to dissolve (and smooth) HIPS - xylene and D-limonene. If we compare them to commonly used for ABS smoothing acetone, then we see a much higher boiling point (acetone - 56C, xylenes - 138-144C, limonene - 176C), which means lower vapour concentration. Acetone at room temperature has partial vapour pressure 200mmHg, xylenes - 5-6mmHg, limonene - unknown. At 100C xylene has pressure 200mmHg, giving probably the same speed of smoothing for HIPS as acetone for ABS at 20C. Xylene is a more significant occupational and environmental hazard, comparing to acetone, so I decided to create this setup, which returns xylene vapour to the vessel by condensation. I do not have limonene handy, so I didn't test it. The deflector and condenser are printed from PETG, and it seems only suitable filament for this task. Chemical resistance datasheets promise that PET is resistant to room temperature acetone and xylene, the additives for printability can be more soluble. The construction is oriented to use a glass jar or beaker with 90mm ID and cap with 2.5mm thickness. There are 2 mutually compatible versions of both condenser and deflector. The second version seems much less challenging for the printer, and I didn't print the first version (but the test cutout was printed decently). The stand for a part I brazed from 1.25mm brass rod using L-Ag20 alloy (colour matched with brass), but you can bend it from any wire or repurpose some kitchen utensil. I used this setup to wash some parts in boiling acetone. While this process the dripping rate was ~0.5 drops per second and I smelled the acetone from <20cm distance. After 2 processes the deflector (not necessary part in this process although) started to warp. Then I used it for the original purpose. The amount of xylene (2ml) I calculated as 5x excess relative to the mass of 600ml of vapour at 100C. 20 minutes were enough for decent smoothing. After closing, there was no xylene smell, even when I stick nose to the vent. There was no additional warping or other destruction of the condenser and deflector after this process. Additional materials: air-tight glass jar (90mm ID, 2.5 cap thickness, not screwed, but with a soft rubber seal with a small hole; do not use a can with a screw cap, it will be dangerous) hot water cold water 2-3 ice cubes 2ml xylene 1.25mm brass rod (optional) L-Ag20 brazing alloy (optional)

With this file you will be able to print Setup for HIPS smoothing in hot vapours with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Setup for HIPS smoothing in hot vapours.