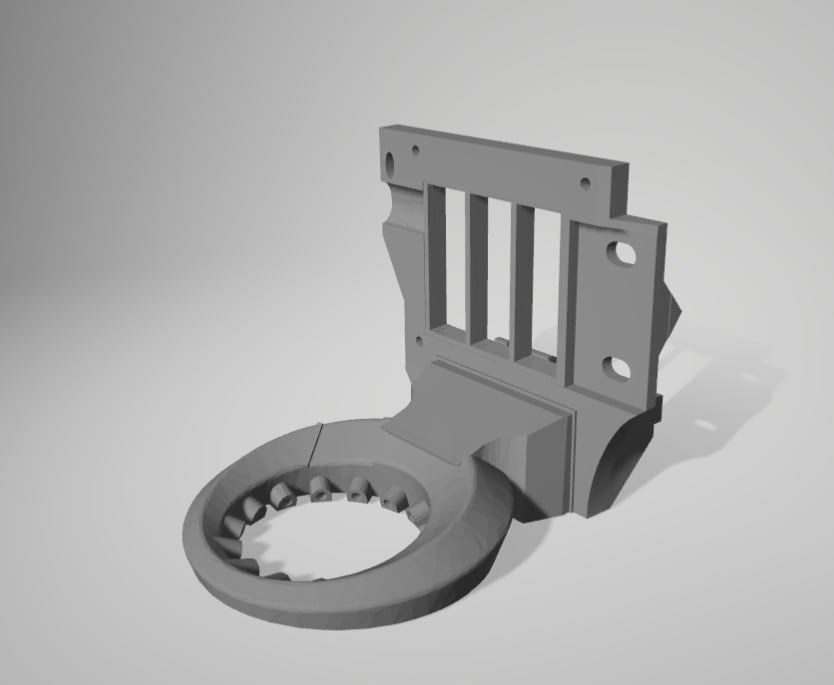

Kobra NEO fan duct upgrade V9.3

thingiverse

Jun 12. See new version V9. I uploaded the wrong file last week (it will still work but isn't as tuned). Made a few changes based on feedback. Note, although the body comes close to the heat-end I have had no melting issue and that is with PLA+, I still haven't printed one in PETG yet, or used a printhead heat temp above 225. Have now printed approx. 200 hrs with no droop or melt with PLA+. Have removed/installed 4 times for nozzle changes, do not overtighten. May 23. See new version V7, as I finally got around to making some upgrades, that include: 1 - Elongated mounting holes as some rubber heat covers are larger and need to shift to one side; 2 - Moved air ring inwards 1.5mm to better center and avoid rubber cover; 3 - Tilted air ring 1.5 degrees to keep air ring above nozzle tip; 4 - Increased inside cavity to permit increased air movement; 5 - Thickened lower wall, this decreases distance to bed but limits droop; and 6 - Removed fan holes, as some fans are different dimensions, make your own holes slightly smaller than the screw, do not overtighten. Note: When I changed nozzles I noticed that the newer nozzle isn't as long and therefore the clearance is lessened. Be advised that nozzle size (total height dimension) will make a difference. Also you may notice some droop in upper bridge, if your printer doesn't bridge well, not an issue as it does not effect outside dimension.DO NOT USE SUPPORTS, will clog interior air pathway. Use at own risk, if using PLA, drooping can occur. Original posting: This is a remix of combination of Vap3Lif3_MCMXCV fan duct that was designed using https://www.printables.com/model/378928-anycubic-kobra-neo-fan-duct by Martin. The circular fan duct was found on the internet (no idea where I got it, can't seem to find it again) and has a 30 degree outlet which directs air flow directly in line with the bottom of the nozzle. V1 - remix of the three .stl files, did not include the fan screw holes to permit use of different fans V2 - added diagonals walls in the the "chute" to better direct air flow Note: it is best to print in PTG or ASA due to proximity to the nozzle. Have successfully used the PLA printed duct for many prints but found it may "droop" slightly on 6+ hour prints. Users have used heat to bend outer edge up. V3 is in the works to allow more distance between bottom of unit and bed (printed item) and thicken the lower wall.

With this file you will be able to print Kobra NEO fan duct upgrade V9.3 with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Kobra NEO fan duct upgrade V9.3.