Kodama Trinus E3D v6 mod v1

thingiverse

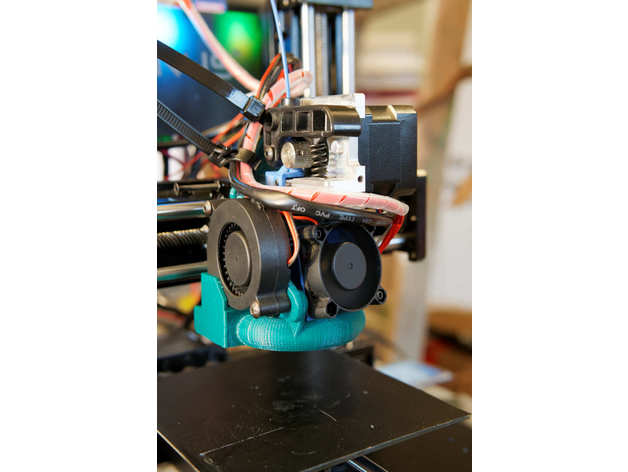

There is no need to discuss the E3D v6, as it's a state-of-the-art reference hot end that you won't surpass. The question remains, what's the purpose of this mod and how does it differ from the Trinus hot end? Even the E3D v6 comes with a PTFE inliner, making it a full-metal hot end, limited only by the Trinus firmware's maximum temperature restrictions. No PTFE degradation or changing extrusion problems over time are issues with this mod. Unstable extrusion and retraction problems are also eliminated, as printing speed is now restricted by Trinus resonance issues rather than the hot or cold end's extrusion capacity. I print PETG infill at 230 °C with a 0.2mm layer height and 80-100 mm/s without any problems. Prior to this mod, I struggled to achieve 20 mm/s without issues, but now I can reach speeds of 80-100 mm/s for certain prints on my small build volume. While this may not be suitable for all prints, it makes a significant difference in printing at average speeds of 60-80 mm/s compared to the Trinus hot end. To access the nozzle and heater block for maintenance, the fan duct can be easily rotated by 180 °, giving free access to these areas. This is seen in the last picture above. 3D Printed Parts: All parts can be printed without supports, using three outlines and 15% infill. They work with both 0.4mm and 0.5mm nozzles and various filaments. The "filament guide for extruder alu-block" is a great option to keep the filament in place. Trinus 40mm Cold End Fan: The E3D comes with a 30mm cold end fan, which is fine, but the 40mm Trinus fan provides even better cooling if you want to use it. Another advantage of the Trinus fan is that its electric connectors will fit perfectly. To attach this fan, print the part "trinus_40mm_cold_end_fan_mount_E3D". Hot Air Shield (Not 3D Printed): Optional, depending on your needs. If you notice temperature drops when close to the bed or too high cold end temperatures, block the air moving upwards with a hot air shield made of insulation cotton, recycled cardboard, or metal. Simply place a piece of cardboard between the E3D heat block and the E3D cold on cooling block. Used with lower temp fan duct to prevent air from getting towards the heater block/cold end. Pictures: 1. Mod in real life with 40mm cold end fan mounted 2. Overview, 40mm fan, extruder/alu block and filament guide not shown 3. Mounting plate for E3D, 5015 hot end fan and fan duct and extruder alu-block 4. Fan duct for higher temperature filaments (> 200-220 °C) 5. Fan duct for lower temperature filaments 6. Mounting bracket for E3D 7. Filament guide for extruder alu-block 8. Trinus 40mm cold end fan mount, instead of standard 30mm E3D fan 9. Overview, 40mm fan, extruder/alu block and filament guide not shown, fan rotated to maintenance position Outlook and Improvement Potential: Optimize hot air management further. Improve sight to the first layer by modifying the fan duct further. Move the nozzle a few mm up, which will require changing the fan design. Reduce weight further by exchanging the extruder block with 3D printed parts. If someone wants, add a casing. Print Settings: Rafts: No Supports: No Resolution: 0.1 - 0.2mm Infill: 15%

With this file you will be able to print Kodama Trinus E3D v6 mod v1 with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Kodama Trinus E3D v6 mod v1.