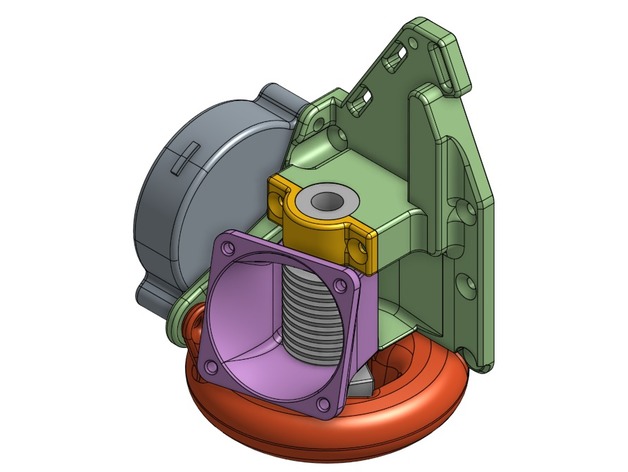

Kodama Trinus E3D v6 mod v2

thingiverse

This is version 2 of the mod. Version 1 can be found here http://www.thingiverse.com/thing:2186559. Differences between V2 and V1: V2 supports also the new bigger heat block of the E3D v6 and not only the small (old) one (v6 lite is also supported). V2 has improved "air management" (less air is directed to the heat block and baseplate, important when printed in PLA), up to about 220 °C there is no temperature drop when using the fan close to the bed. V2 has a stiffer baseplate, helps with higher temps if printed in PLA. V2 the fan duct has a nice snap fit, which fixes the fan duct (it still can be rotated in maintenance position). V2 moves the nozzle about 3 mm up in z-direction. ...and there are some minor changes. UPDATE 28.04.2017: I have added two fan ducts: "fan_duct_v3" is my last iteration step. It provides a better view to the 1st layer, is smaller (prints quicker) and doesn't have the problem all circular fan ducts have. The problem that when the nozzle is close to the bed (or above a horizontal surface), the air is pushed to the nozzle from all directions, but cannot get there because it blocks itself. Compared to the circular versions, it is also much less sensitive to overheating. "fan_duct_PLA_v3", same as "fan_duct_v3" but only the air jets/nozzles are cut back, because when testing, I found out, that when printed in PLA, they deform at higher temperatures. At least PETG, BDP, ABS, ASA or filaments with high heat resistance are much better. 0.1 - 0.2 mm layer height. If you use PLA increase number of outer lines to 4/5 and solid top/bottom layers to e.g. 5* 0.2 mm. Infill about >= 15%, according to number of top layers and material. "E3D_bracket" Use filament with at least same heat resistance as above. 0.1 - 0.2 mm layer height. It is the only part which could be printed using supports, I don't use supports, this gives some unwanted bridges on the horizontal overhang, which can be removed easily afterward, so no supports needed. fan duct Use a filament with the highest possible heat resistance, PLA works for about 210 °C and 50-60°C HTB fine, but higher temperatures will deform it. I use extrudr BDP which survives about 115 °C without problems and can be easily printed at low temperatures, without heated bed and enclosure. The V2 fan duct blocks the air upwards to the heater block by itself better than V1, so this has improved. the fan duct design was optimized for evenness of airflow from all directions, design verified with CFD simulation, the target was not to maximize air flow, because this also can disturb the print, it should direct the cold air exactly where it is needed, therefore much less airflow is needed compared to not circular fan ducts The ducts beside has massive overhangs. They won't print perfect, but that doesn't matter. The duct uses the coanda effect to direct the air to the nozzle. so if the overhangs are rough, it doesn't matter at all and nobody sees it.... trinus 40mm cold end fan The E3D should come with a 30 mm cold end fan, which is fine, but the 40 mm trinus fan will provide even better cooling (sharper transition from cold to hot), if you want to use the trinus fan print the part "trinus_40mm_cold_end_fan_mount_E3D". Another advantage of the 40mm trinus fan is, that the electric connectors will fit. insulation/heat block (not 3Dprinted), if you notice that the fan duct doesn't survive because the lower part "melts/deforms" (especially PLA might melt where the heat block screw is), just put a cardboard or insulation cotton between the fan duct and the heat block Outlook and improvement potential: Optimize air management further. Improve sight to 1st layer --> modify fan duct further, try different (smaller) ducts. Maybe reduce weight further by exchanging the extruder block with 3D printed parts. If some wants add a casing If one needs some small mods of the mod, I could probably change it. Print Settings: No supports. Resolution: 0.1 - 0.2 mm. Infill: 15 % (or above).

With this file you will be able to print Kodama Trinus E3D v6 mod v2 with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Kodama Trinus E3D v6 mod v2.