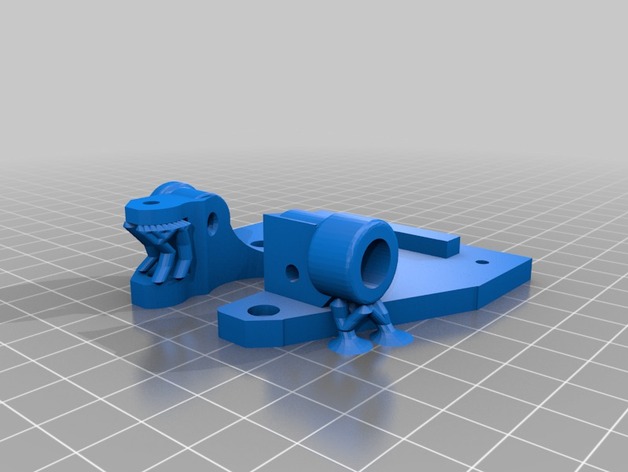

Kossel Bowden Extruder

thingiverse

I tried a number of different bowden extruders before i finally sat down and picked all the features I liked from the better ones and amalgamated them in this one that I use on my two Kossels. This extruder mounts on a 2020 open beam on the Z tower of the Kossel (Delta) and extends to the right side of the printer when viewed from the front. It's a very strong driving extruder and if there's clicking or skipping, it's probably a problem elsewhere. Printed .3 layer height, 50% infill, PLA. Print Settings Printer: Kossel Rafts: No Supports: Yes Resolution: 0.3mm Infill: 50% Notes: For the main body of the extruder you shouldn't have to add any supports, there are some in there from Meshmixer and it's all I found was needed. For the extruder ARM, supports are needed where the bearing will go. I use the default settings in Slic3r for support when printing it. Takes a matter of minutes to chip out the supports. Post-Printing Steps and Parts I drill out the filament entry and exit holes in the main extruder body with a 2mm bit. Gives you a little wiggle room to work with. The filament connector is a 1/8" 27 NPT type since it's far easier to get the bowden tube in and out of in place of those 5mm ones. Plus it makes threading the filament a lot easier (for whatever reason). I use a tap set to pre-thread for the connector. Bearing is a 625ZZ and held in with a M5 x 20 bolt and nut. Don't over tighten the bolt, the bearing should turn freely without binding. The knob design is a press fit, but the STL file also has the insert for the ARM. The insert fits inside the arm as a pivot then the arm mounts to the stepper with an M3 x 25. The other stepper mounts use the standard M3 x 6. Tension is provided by a compression spring. Use a M3 x 25 with washer to retain the spring. The compression spring is 20 x 5 ID, 7.5 OD. eBay labels them as "20mm x 7.5mm x 5mm Alloy Coil Stamping Compression". These springs are fairly stiff so I compress them about 5mm tops. The hobbed gear is a typical MK8 one. Extend the flat spot on the stepper motor shaft to give the gear something to seat into. Last is the "guide". I mount the guide 30mm or so above the extruder, it helps keep the somewhat floppy Bowden tube in a better position during printing.

With this file you will be able to print Kossel Bowden Extruder with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Kossel Bowden Extruder.