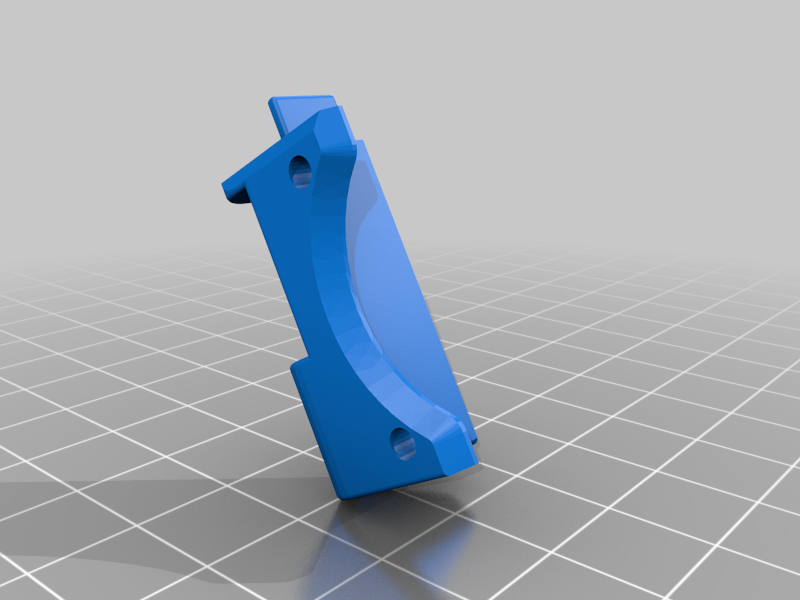

Kyosho Ultima RT5 Chassis Service Pack "REV7"

thingiverse

READ THIS! Important information: RESPECT THE LICENCE! You cannot make money with this! Its my countless hours of hard work poured into this project, all so i could offer this free for you to use in your personal use. If i see anyone trying to make money with this, like somebody tried in ebay with my previous designs, legal actions will be taken against those licence violations. I designed this custom chassis/conversion set (kind of Service Pack) for those who still have Kyosho Ultima RT5 (or would like to convert their SC/SC6 to that, or just build a car like that), but would like to use it in midmotor or laydown configuration (+ rear motor ofc). I´ve also added support for sideways battery, for those who might need that option as well. Currently the main chassis offers 8mm adjustement window for sideways shorty battery option. I know it isn´t much, but thats what the current chassis offers right now. I call this "REV7". REV7 in explained, is my latest and greatest V7 version of my "enhanced Ultima project". Its a driveable and also "bashable" 3D-printed upgrade chassis for old discontinued Kyosho Ultima series cars. The biggest part of the set is obviously the main chassis. It barely fits to Prusa i3 MK3 print bed, but if you rotate it just right and print it without brim, it fits. I've now printed 4 chassis plates myself with my i3 MK3S (havent broken any, i just like to have different setups). My custom chassis plate supports all original Kyosho gearbox styles. 3 gear rear motor, 3 and 4 gear rear and midmotor, and also a laydown gearbox. Easy access diff transmission cases are also in development, no ETA though. Just keep checking out the upgrades I list in here frequently. This set includes: - Main chassis plate - Rear chassis plate - Reinforced rear chassis plate with integrated skid plate (i strongly recommend using this). - Midmotor rear bumper - 3D printable laydown motor mount plate with integrated spur gear protector (drill additional screw holes yourself if you need those). Just mirror this in your slicer if you need to swap it around depending if you use 3 or 4 gear laydown gearbox configuration - Chassis support cradle for rear motor configuration - Chassis support cradle shim (always use this with rear motor support cradle) - Custom rear motor bulkhead - Custom midmotor bulkhead - Custom rear shock tower (same part is compatible with rear motor and midmotor configurations as well as with laydown). - Midmotor waterfall brace - Custom front upper chassis plate - Custom front bulkhead (reinforced) - Custom front steering bellcrank arms (these are just slightly shorter than SC6/RB6 arms, use 5x8x2,5mm ball bearings in these) - Custom front steering bellcrank link/ackerman plate (you need 3x7x3mm ball bearings for these) - Steering bellcrank bearing height shims (you need to use these or your own shims to have bind free bearings). - Custom front bumper - Custom front lower chassis plate (reinforced) - Front shock tower (for stock RT5 front lower arms) - Gull Wing front shock tower (for Associated T6.2 front lower arms) - Front hinge pin plate (38mm wide) - Front hinge pin plate (40mm wide) - Front hinge pin plate shim (0,5mm thickness) - Front hinge pin plate shim (1,0mm thickness) - Rear motor inline battery tiedown plate - Body holders for rear motor configuration (body hole locations are the same as in RT5, so no need to drill additional holes). - 12mm wheel hexes, original offset (these might be a little tight for original pins, but install these to wheel first and then press them to place with tightening the wheel nut). Im using these as my original ones were so sloppy). Chassis details: - Stock length (if you want to use this with RB5, you need to slice it 23mm:s shorter to have stock RB5 length.) - Support for midmotor standup (3 or 4 gear) - Support for midmotor laydown (3 or 4 gear) - Support for rear motor (3 or 4 gear) - Support for long brushless motors in all gearbox configurations (Like Team Orion dDrive with integrated ESC). - Support for "normal" length brushed and brushless motors. - Support for midmotor 30mm fan (no matter if the car is in 3 or 4 gear gearbox configuration, just mirror the fan mount in your slicer before printing if needed). - Support for inline 3S in rear motor configuration. - Support for inline 2S shorty packs for midmotor configuration (if you want inline 3S with LD, you need to use low profile steering servo). - Support for sideways 2S shorty packs in all gearbox configurations (if you have Low shorty packs, just use different length chassis body posts/aluminum spacers to get the correct height for the battery holders). - Support for stock RT5 front suspension arms. - Support for stock SC6 front suspension arms. - Support for Team Associated T6.2 gull wing front suspension arms. - Support for Team Associated T6.2 flat front suspension arms (in development). - Supports stock RT5/RB5/SC gen1 front end parts, except for the front upper plate. If these parts are used, the steering servo position needs to moved from the front to the back. Newer generation parts are not compatible due the difference in chassis material (it´s virtually impossible to design durable FDM 3D printed parts to replace the aluminum main chassis plate that the newer car has because of the space limitations). The custom front upper plate for RB5 style front end is in development, no ETA. - Chassis flex is adjustable with multiple different ways. Supporting parts infill, material, adjustable flex plate system, using different body posts and battery tie down options. - Design is pretty much optimized for 3D printing (except parts that marked as prototype), so the parts are also durable and usable. (Im using all the parts in this set in my own cars). What extra parts are needed? You need various length of 5mm OD M3 aluminum chassis body posts from ebay: https://www.ebay.com/itm/224390616069?hash=item343eb91405:g:~b0AAOSwCy1gUsri This comes from my memory, but you need: - 2 pcs of 15mm posts for steering arms. (stock aluminum posts are not compatible, i didnt have those, so design is missing compatibility for that hex end of the stock posts). You can also use these same posts in gearbox as an idler axle. As these are hollow, they are even more lightweight than the original steel or aluminum idler axles. - 2 pcs of 25mm posts for front upper plate middle points. - 2 pcs of 20mm posts for front upper plate rear points. - 2 pcs of 30mm posts for midmotor waterfall brace. - 4 pcs of 20mm posts for rear motor configuration rear battery tie down plate (or 2 if you want more flex). I would advice for just ordering enough of anything, so you can fiddle around with different battery heights etc. These are cheap. You also need heat pressed M3 brass inserts: https://www.ebay.com/itm/203608961927?_trkparms=ispr%3D1&hash=item2f680a3387:g:VbAAAOSwCs1hRFt0&amdata=enc%3AAQAGAAACsPYe5NmHp%252B2JMhMi7yxGiTJkPrKr5t53CooMSQt2orsSjVt3vLKCbov98Z19qhuwYx1SHgZvoQX%252FMp4X20rdzrhaBOvNx9euEsu11jyWRazgwqGKX1IsYB7DPyBlnRyOm%252B%252BfcA%252FBkjjLPItnnoAQwmnBHpOhUaorIG3iXipptn251OoVmZfiLr8uudHo3aM4PrlAl%252BuEjPR4zDR6m9Imk7SWBqCPCa72EzLIFWdMkuz2IxQs4J1H%252FqWen1nz1PsDlktjZ2HXyY4vUyOt2v8RvOqVgofBqgaVYiWgBkJlEklnf6yTTlyJBm8d2wtEuH2jhaOLQ0HbtIYk1JZq%252BiJ2%252BMTH5PduKQC0W1rn%252BNZ82sGGROpAkjTIsZcr%252FC8KDDZ7diQuseU9wSeF6I3tcQxW5lgM%252B5rNjYZAa8PhbBhUfZMbFOsM1H5W9xiT5XzI8MFUU9xDsxsCpRbUF8HAhjvljCU51y1PcRyC5ZDCuVlUnzJfuHK74uR372tOZkRM1XihdzFXQ7TcsDwOhaamQBF9DyzPVD8ifdKbcTzXoCBzW5h1M7oPDUHvwhuIQjnmCy9dnVbhVX6S3alhxmD0Xjzl8XGobi5IC5WRQ0Uz0k0GX70k5iJPxzY9rF4JkjRg5b%252Bo0Hl%252FsMieJPHH8OfjsJyAl4WuoPhI8aMiM%252FKN5xD8PRIeRwD%252FELV9Ndfzftx%252FWf%252BQLJ2xXvJdgpN8TWgmiZkVKokhXA5S0KoPK7Qi7MXBSe4Smm%252B2r%252BuFiBqzjubOSrwF2Sx16JGHKg0b%252F2kyIpBz3laYC5CvB1oHWIS77K58xMXwloKTyM6eSSYovGVVWdhj3M8PHKTsOP6u%252BJ%252FHpXn40Hfd8Laa6Pgnkf55p4PMIbbAjPUIXkdT6kkbUjj8eXux5dynZXIt95x5r7Re1ZBO9%252FA%253D%7Cclp%3A2334524%7Ctkp%3ABFBM6pO-qaxf - You need 2 pcs of those inserts to rear chassis (3mm height, M3 thread, slightly over 5mm of OD.) - And, you need 2 pcs of those same inserts to front bulkhead. The screw which bolts through the upper plate to the front bulkhead needs these, as otherwise the forces will tear the screws off from the printed material. ^ These inserts are critical for durability! As for the servo arm, only the arm from this set is compatible because of the space limitations: https://kyosho.fi/spare-parts/2906-servo-saver-zx5-fs2-sp-rb5-sp2-wc.html I think you need to find an replacement for those servo arms, as those Kyosho arms are getting more and more difficult to find. "JConcepts 2850 25T ALUMINUM SERVO HORN - B6, T6, SC6" seems like it would be a great replacement, but do your own research. I would have ordered this arm, but it it isn´t in stock in anywhere in our local RC-shops, so i have to wait until it re-stocks. - You also need these bearings for the steering arms: 4pcs of 5mm id, 8mm od, 2,5mm height. - And also 2 pcs of 3x7x3 mm bearings for ackerman link (i designed a ball bearing ackerman link, because the stock design has too much slack. My design doesnt have any slack if printed using filament i recommend). If using laydown, you need laydown gearbox compatible rear suspension hinge pin front holder (stock Kyosho holder that comes with Laydown gearbox set), or then you need to shave the original rear motor front hinge pin holder, so it clears the laydown gearbox, i just use the modded "RF2" holder. I can only guarantee the dimensional accuracy of the holes and designed chassis flex if you print this with Formfutura CarbonFil Black PETG/CF. You can probably get away with some parts printed from different material, but thats up to you to test. Nylon CF is also okay, but its hard to print and it flexes more than CarbonFil Black so i dont see a point of printing these parts from Nylon. I have an prototype chassis plate thats printed from PLA and it seems stiff enough to be driveable as well. The filament im using and what i strongly recommend: https://www.3djake.fi/formfutura/carbonfiltm-black You also need to have some SC/SC6 or RT5 parts for this conversion: - Front lower suspension arms (or Associated T6.2 gull wing front arms). - Rear lower suspension arms (DB/SC/SC6 or RT5/RT6 rear arms). - Front C-hubs (RB6/SC6 or RT6) - Camber links (turnbuckles) - Steering links (turnbuckles) - Ball bearings - Ball studs (Sakura makes cheap 4.8mm aluminum ball studs, check ebay). - Complete shocks (RT5/RT6/SC6 length). - Complete gearbox/motor assembly - Servo posts - Stadium truck body - Front body holder. You can either use RT5 holder, or Ultima ST holder, which works great for older bodies). - Screws, hinge pins, axles and other small misc. parts. The design is missing: - Battery tie down plate for inline battery (as im designing an adjustable option for it). - Front body holder - Adjustable chassis flex plate system is still work in progress. Chassis already has a support for these plates, but the plates need some work. - Steering ackerman link doesnt have capability to swap it around to adjust ackerman. Its impossible to do that option with 3D print. So option is that you use stock RT6/RB6/SC6 ackerman link, or wait for me to design 2 different links to adjust ackerman with ackerman link swapping. You can currently do a minor adjustments with shimming the ball joints. - Optional receiver mounts in front and rear. Now i just mounted my receiver on top of the steering servo. But yea, its already driveable and also interesting enough, bashable. The main chassis design isn´t changing from this, so you can print the chassis and trust that i will only update the supporting parts if theres a need for it. If the parts in your slicer look to be in a strange angle, flip it 28 degrees (thats the front bulkhead kickup angle) in x axle and then after that either 90 or 180 degrees for your preferred printing orientation for the part. Some parts need supports, some wont. Design and build thread: https://www.rc10talk.com/viewtopic.php?f=30&t=46687&p=529096#p529096 And other thread: https://www.rctech.net/forum/electric-off-road/1092568-ultima-rt5-3d-printed-custom-upgrade-chassis.html Edit: 28.11. Added front wheel bearing/steering hubs for the package, because you need SC6,RT6 or RB6 style hubs for steering geometry to be correct. You cannot use RT5 stock hubs. C-hubs should be fine from RT5, but if you want to have more adjustability, use RT6/SC6/RB6 hubs. Edit: 17.12. The front shock tower is a known weak point when doing jumps (with bad landings) with this chassis. The 3D-printed front shock tower will snap half just over the 4 screws where it attaches to the front upper plate, if the shock will bottom out during hard landing. I will fix this with reinforced design when i have some time. If you want a quick fix, use stock Ultima RT5 front shock tower. Edit: 19.12. Added new shock tower design to the package. "REV7 Front Shock Tower Reinforced". Use this instead of the old design. This should fix the cracking problem with hard landings where the shock bottoms out. Edit: 18.4. Added rear motor body holders to the set. No need to drill additional holes to the body, stock RT5 body will work with these holders. Edit: 9.5. - Added reinforced rear chassis plate. It has an integrated 3mm skid plate, which should beef the critical area of the plate nicely. In my own tests, the original design cracked too easily in roll-over situations. The original designs weak point is where the rear motor gearbox front screws bolt on. This new design should fix that problem, but keep in mind its experimental and now the part needs supports when printing it. I tested the original design with CarbonFill Black and Nylon CF, both cracked from the same area. - Added 12mm wheel hexes. - Added front hinge pin plate 38mm. - Added front hinge pin plate 40mm. - Added front hinge pin plate shim 0,5mm. - Added front hinge pin plate shim 1,0mm. - Added midmotor rear bumper. I havent tested this myself as i dont use rear bumper in my midmotor version of this car, so this is just Fusion 360 design. Report if you have problems. On my recent tests, i also confirmed that the front wheel hubs (where the wheel bearings will be installed) is more than okay to be 3D printed. I have bashed the car like crazy and i havent had a single failure. The original front lower suspension arms are breaking instead of the front wheel hub, so i think it confirms those 3D printed parts are usable. Edit: 15.5. - Added reinforced front lower plate (REV7 front lower plate reinforced.stl) and compatible front bulkhead (REV7 front bulkhead reinforced.stl). This version beefs up a critical area of the front lower chassis plate and i strongly recommend using this instead of the original design (old files deleted). This new version is not compatible with the previous bulkhead design, so if you print this, use the updated front bulkhead (REV7 front bulkhead reinforced.stl). - Added sideways battery holder flaps (print 2 of these). Edit: 16.5. - Fixed the ackerman steering link clearance problem. Removed the old file and uploaded the new one (REV7 steering link clearance fixed.stl). - New slightly modified rear chassis plate added. No need to switch from previous design. This newest version just adds a little bit more space to the rear control arm pin holder area. Edit: 17.5. - Slightly modified midmotor rear bulkhead design. The design change allows the swaybar to be mounted using only 2 M3 screws, instead of using separate plastic inserts with screws. I also added second swaybar position, which could be used if the upper swaybar location causes swaybar to hit the rear camber links. Edit: 15.6. - Studied possiblity to use Team Associated RC10 T6.2 Front lower suspension arms in REV7. Straight arms are direct swap with some extra shimms used and with T6.2 hinge pins (which are just slightly longer than RT5). Longer shock absorber lower ball joint (the plastic part) is also needed. Front arms are same length as RT5 (And as usual, RT5 arms are pure pain to find nowadays. Ultima SC6 front arms are shorter than RT5 arms, so those cant be used). Also T6.2 gull wing arms are compatible. I ordered a set and tested it myself. Im going to design a new front shock tower for gull wing arm geometry. With these arms, you can fine tune corner entry/mid-corner/corner exit behaviour even more than usually. Stay tuned for updates! Edit: 20.6. - Added experimental shock tower (REV7 Gull Wing front shock tower.stl), thats compatible with Associated T6.2 gull wing front arms. Theres still some tweaking to be done with this shock tower, but i will update it later once i test it more myself. You can still print it and drive with it, and theres no fitment issues. Edit: 22.6. - Added 30mm fan mount. The released mount is designed around "ValueRC 30mm aluminum fan" ( https://hobbyfactory.fi/p60977/valuerc-alumiininen-tuuletin-30mm ) and its for the 4 gear laydown. If you are using 3-gear laydown, mirror it in your slicer and then print it. Use 30mm aluminum body post/spacer with this mount. Design isn´t fully optimized for 3D-printing, so the current version needs supports (everywhere).

With this file you will be able to print Kyosho Ultima RT5 Chassis Service Pack "REV7" with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Kyosho Ultima RT5 Chassis Service Pack "REV7".