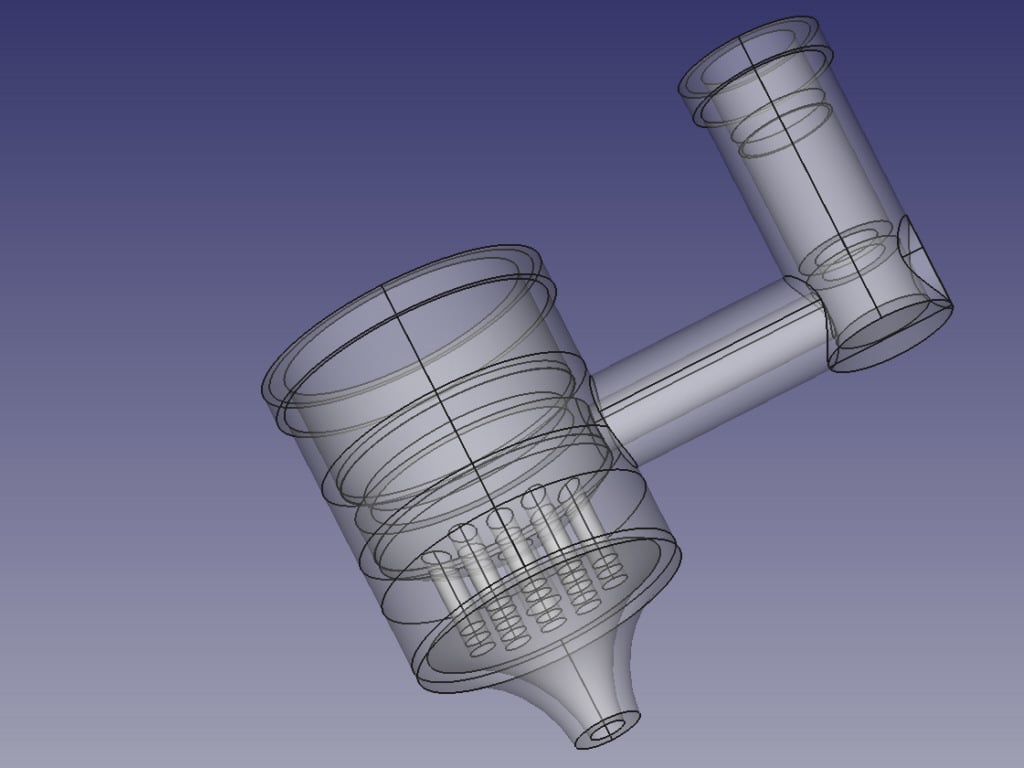

Laminar air assist for laser with 15mm focus ring (VigoTec VG-L7, KKmoon BX20)

thingiverse

AIR ASSIST FOR 15MM LASER HEAD OF VIGOTEC VG-L7 / KKMOON BX20, WITH LAMINAR FLOW DESIGN ======================================================================================= PURPOSE ------- An air assist is a device that directs a steady flow of air to the focus point, to blow smoke and cutting residue away from the material and from the optics of the laser. Without it, smoke can obscure the beam, contaminate the lens and degrade cut quality. COMPATIBILITY ------------- This air assist fits the 20W "Vigotec VG-L7" laser, also sold as "KKmoon BX20" (2021 model). That's a diode laser with Ø15mm focus ring. The focus ring is 10mm high. ADJUSTABLE Z AXIS REQUIRED -------------------------- The air assist is designed to be pushed over the laser's focus ring (friction fit). It will turn the laser into a fixed-focus device. You will no longer be able to turn the focus ring. That means you must install an adjustable z axis behind the laser head. You can then focus by moving the entire laser head up or down. Such mechanisms are available on aliexpress. I chose a “laser head adjustable module mounting frame" from seller TWO TREES Official Store. That’s a z-axis with linear bearing rail. It was modded slightly (https://www.thingiverse.com/thing:5206001) but that's not necessary. Note that the added weight of this z-axis topples the one-armed VG-L7 if the laser head is driven to the end of its axis. If you must drive the head to such positions, elongate the feet of the device or choose a lighter z-axis. DIMENSIONS ---------- The height of this air assist is 29mm. 9mm of it are designed to slide over the laser’s focus ring. The air assist thus occupies 20mm of the focus distance. 3D PRINTING ----------- The stl file is intended to be be printed at 0.05mm resolution with a *resin printer*. FDM printers will not achieve the required print quality. In "nozzle.stl", the hole for the Ø15mm focus ring has a diameter of 15.15mm to account for shrinking. The alternative stl files with +0,05, +0,1 etc. in the name have slightly smaller or wider holes for the focus ring. Choose the one that is the best fit if printed with your 3D printer and your resin. Print in an upright position, i.e. top of nozzle pointing straight upwards. This will create a razor-sharp nozzle, which is important. In that orientation, the object is designed to be printable without supports except on the underside, where you should place lots of them. Do not put supports into the inner cavities. I’ve printed it with a LD-002H and Weistek’s ABS-like white resin, mixed with 10% Monocure Flex 100. You may have to unclog a hole or two in the laminar flow section after UV curing. If that happens, push in a 1.2mm drill from your Dremel and rotate it with your fingers. TUBING ------ You will need 2m–3m silicone tubing of type 6×3mm (that means outer diameter 6mm / inner diameter 3mm) to connect the air assist to your compressor. Such tubing can be pushed over the quick-disconnect couplers of most air compressors. 6×4mm is probably a bit too soft. AIR COMPRESSOR -------------- I currently use an oil-free 23l/min airbrush compressor with tank, “AS186”. However, that’s not the best choice, at least for longer jobs: This air assist has a 2.0mm exit nozzle. Airbrush compressors are designed for 0.2mm – 0.5mm nozzles. They are unable to build up pressure in their tanks with a 2.0mm nozzle, it lets out too much air. That means they'll run constantly and ultimately overheat. There are compressors with higher flow rates designed for continuous operation, such as the Hailea ACO-318 32W air compressor (60l/min). However, I have found that the actual throughput is lower than that of my airbrush compressor if a 2.0mm nozzle is used: The Hailea compressor doesn't deal well with counter pressure from a nozzle and it doesn't deal well with 6x3mm tubing. Also, the vibrations coming from the Hailea compressor are intolerable. They affect the 2.0mm air assist like a hammer. For a Hailea compressor, I have found that the nozzle should better be 3.5mm and that 8x5 tubing should be used. Even then, it will have 30% lower throughput than the airbrush compressor. INSTALLATION --------------------- 1. Begin by installing an adjustable z axis on your laser. Do not yet install the air assist. 2. Operate the adjustable Z axis and move the laser head to the desired focus distance, for example 25mm above material / focus sheet. This choice will leave a 5mm air gap between material and air assist, once installed. You can not go below 20mm since you will need at least that much space for the air assist. Your laser must be able to focus at the distance you choose. That depends on the installed lens. 3. Turn the focus light on (0.1% laser power) and focus the laser to the smallest dot possible on black material. 4. Turn the laser off. Push the air tube into the air assist's tube connector. Approximately 10mm of tubing should slide in. There is a built-in stop. 5. Push the air assist over the focus ring of your laser, without changing its position. Orient the tube connector of the air assist towards the beginning of the arm on which the laser moves. Approximately 9mm of the laser's focus ring should slide into the air assist. There is a built-in stop. You must achieve a tight fit. There must be no chance of the air assist coming loose. If that is not the case, print a different stl file – slightly larger or smaller. 6. Use cable ties to loosely attach the silicon tubing to the cable leading to the laser head. 7. Turn the focus light on (0.1% laser power) and check that the beam passes through the centre hole of the nozzle and doesn't hit and burn the 3D printed material. AIR FLOW -------- Air flow improves cutting quality but if your flow is too aggressive, the cuts could degrade because too much O2 creates a mini blast oven inside the cut area. Laser a grid of test lines of increasing laser power (depth) to find the optimal valve setting for your compressor and material. LICENSE ------- Licensed by dtmr-thingieverse@tutanota.com under Attribution-NonCommercial-NoDerivatives 4.0 International, in short CC BY-NC-ND 4.02 (https://creativecommons.org/licenses/by-nc-nd/4.0/deed.en). You are free to: * Share — copy and redistribute the material in any medium or format * The licensor can not revoke these freedoms as long as you follow the license terms. Under the following terms: * Attribution — You must give appropriate credit, provide a link to the license, and indicate if changes were made. You may do so in any reasonable manner, but not in any way that suggests the licensor endorses you or your use. * NonCommercial — You may not use the material for commercial purposes. * NoDerivatives — If you remix, transform, or build upon the material, you may not distribute the modified material. * No additional restrictions — You may not apply legal terms or technological measures that legally restrict others from doing anything the license permits. EXCLUSION OF LIABILITY ---------------------- This design is provided as is, free of charge, without any warranties. Use at your own discretion. In no event shall the author be liable for any direct or indirect or consequential damages or any damages whatsoever, even if author knew or should have known that such damages were possible.

With this file you will be able to print Laminar air assist for laser with 15mm focus ring (VigoTec VG-L7, KKmoon BX20) with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Laminar air assist for laser with 15mm focus ring (VigoTec VG-L7, KKmoon BX20).