Laser Cut 1,594,323:1 Gear Reduction

thingiverse

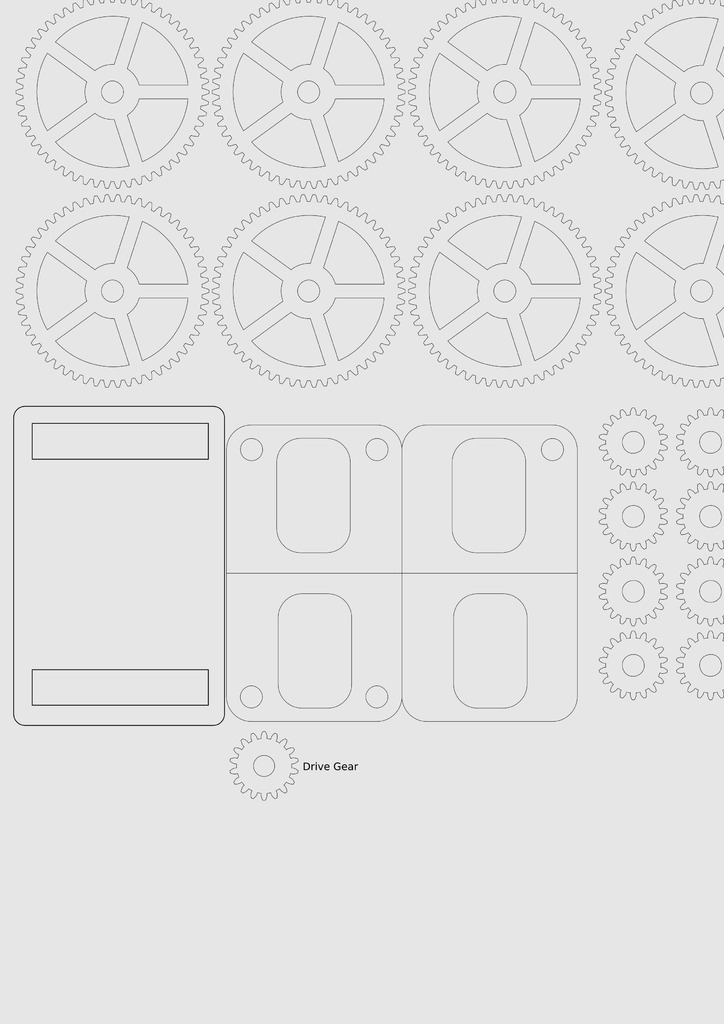

This is a take on some of the museum installations that illustrate gear reduction. Spinning the drive gear at 50 RPM should make the end gear turn around once every 22 days. Add more gears to reduce further. It was designed for 5mm thick plywood. I sized the gear holes for some 6.4mm aluminum bar stock that I had on-hand. When assembling it, each of the large gears should have a smaller gear glued to it, except for the last one. The 'drive gear' (marked in the SVG) should fit the drive shaft as snugly as possible. All of the others are free-spinning. See the video for how it should all fit together.

With this file you will be able to print Laser Cut 1,594,323:1 Gear Reduction with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Laser Cut 1,594,323:1 Gear Reduction.