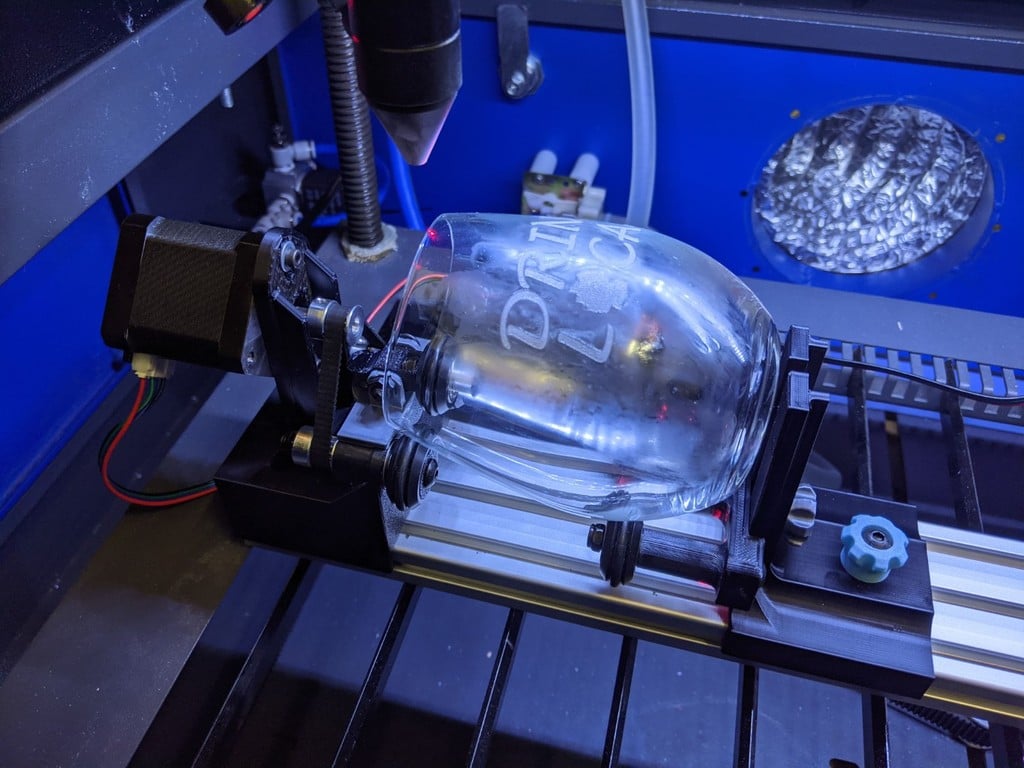

Laser Rotary Axis - Taller, Wider - For Stemless Wine Glass

thingiverse

I ran an issue trying to laser engrave stemless wine glasses. To get the glass level I needed a much wider Idler Bracket. Once I did that I figured out that it didn't have enough "umpfh" to spin the glass consistently. Thus I added an idler arm to hold it down and then had to raise the entire motor mount. Raising the motor mount meant I needed to increase the height of the Rail Slider as well; so I did. I made the hold down part removeable so that you can still reach the screws holding the motor and certain long objects need there to be nothing in the way on the moto mount. Running with the arm mount included even without the arm has prevented the round objects from moving; I just bump them against the Hold Down and it works great. Hardware required: * M5 lock nut (x1) used in the arm * M5 nut (x1) used to hold the arm to the attachment * M5 25mm screw (x2) - used to hold the v wheel to the arm and the arm to the hold down * M3 cap screw * M3 heat insert * Delrin V Wheel Kit (or a smaller hard wheel should work too) * Rubber O-Ring (x1) * 6mm Spacers - only if you are using the small arm (note: I needed the small arm for enough force for my stemless wine glass) * Spring - I used a random spring from a large pen that was laying around. This makes the arm push down on the glass 3d Printed Parts Since I screwed up and ordered the wrong aluminum extrusion you get the benefit of I (i) slot and V slot capability * Remix: Rail Slider Taller (pick i slot or v slot) * Remix: Moto_Mount_Taller_Raised (pick i slot or v slot) * Remix: Arm-Small (or go Arm-Long depending on the type of item) * Remix: Hold Down * OPTIONAL Remix: Idler_Bracket_Wider (or use the regular one OR go super wide with the 70mm version, note: I have not needed the 70mm wide one for any items thus far) * The remaining parts come from the original: https://www.thingiverse.com/thing:3906379 Use supports touching build plate only. For the arm I used a support blocker on the hold for the nut since those supports aren't really necessary. Assembly: This only covers parts that are different from the standard build: * For the arm insert one M5 nylon lock nut and then use a M5x25 to hold the arm to the hold down mount * Heat insert the M3 insert into the Moto_Mount piece * Use an M3 screw to hold the hold down to the moto mount * Use another M5x25 and the spacer and the V wheel with O ring to connect to the arm. If you use the long arm you don't need the spacer. To setup: 1. Install the hold down using an M3 screw 2. Connect the arm the arm to the hold down with the M5x25 and regular nut 3. As required use the wider idler bracket The .3mf files come in correctly oriented. P.S. I included the fusion 360 files I used to remix this. The flow is very poor but I provided it anyway.

With this file you will be able to print Laser Rotary Axis - Taller, Wider - For Stemless Wine Glass with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Laser Rotary Axis - Taller, Wider - For Stemless Wine Glass.