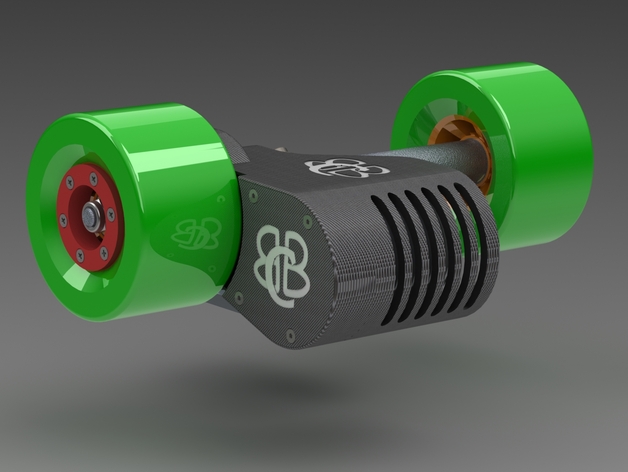

Longboard Motor Mount

thingiverse

After long time of trying around with different designs I reached now the design V.0.7.1 which is already tested for more than 100++ km. During the different tested Versions I ended up often with cracks at different spots. A motor mount brings the FDM printed part especially on long term to its limits. That's why the requirement of 3 reinforcement parts are required. One is a cnc milled motor plate. I used aluminum of 3 mm but also carbon or a fiberglass plate can and should be used. These materials are also easier to work with. So you can also handcraft them. One further disadvantage of aluminum is , that it has a bad bonding with any glues I use. I ended up twice with a delaminated aluminum plate. So it was necessary to drill a couple of holes in the aluminum to get a better bonding. So I recommend here CFK or glass fiber plate. The other one is a braze part that you can see in the pictures. It is necessary to spread the forces around the clamp screws. Because it happened that at these parts the printed layers delaminated in the middle of the holes (I used here carbonfill). These bras parts you can get as bar stock from you local hobby store. (e.g. here: https://www.conrad.de/de/messing-halbrund-profil-l-x-b-x-h-500-x-8-x-4-mm-222309.html for germany) It can easily be cutted in parts and drilled using the also published template. You need one part with two holes 4.5 mm an one part with two holes 3.2 mm to cut a M4 thread in. The Version V 0.8 has now also a covered belt (9 mm) because during the test with V 0.7.1 the main remaining problem were little stones coming under the belt and needed to be removed manually. This version be ready for test soon, but is already available here. It is available in a Version for the gunmetal truck and one for the caliber truck. At the moment I only tested the gunmetal Version. So testers are welcome. The gun metal truck must be filed round in the middle as shown in the picture. That is easily done. I used a NTM Prop Drive 50-60 270 kV from Hobbyking. But this motor is not anymore available. But you can use every Motor up to a diameter of 50 mm and a mounting hole distance of 30 mm. I use a 9 mm belt. Wider will be a problem. I printed different material like PLA and Carbonfill. PLA was not that bad than expected. And now with the new reinforcements it should work easily. Carbonfill is a cool material with a nice look, good print results and stiffness. The only problem I had was that I get often delamination of the printed layers on high forces. That's why you can see the one motor mount on the photos covered with a laminated carbon fiber layer. And: It looks cool as well. I found now a cool new materal called ApolloX from formfutura. It has a high temperature durability and good stability (like ABS) but without any warping on first layer problems. I used this for Version 0.8. But I covered it also with Carbon due to the cool look. Release history up to Version 0.7 Test Versions with hunderts of test kilometers. 0.7.1 Tested and released Version with perfect results. 0.8 Added Belt coverNow also for caliber truck To stay up to date with new Versions follow me also on facebook: https://www.facebook.com/berlincustomboards/

With this file you will be able to print Longboard Motor Mount with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Longboard Motor Mount.