MakerWare Profiles for Polycarbonate on an R2x

thingiverse

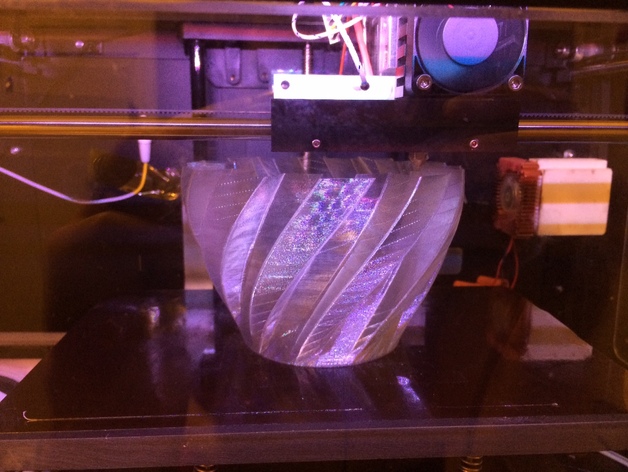

Here are some MakerWare profiles that I have been using with Polycarbonate on a Replicator 2x. PC is: Crystal-clear like T-glase About twice as strong and tough as ABS, but stiffer than Nylon Suitable for mechanical use up to ~150C Prone to warping like ABS THIS IS EXPERIMENTAL. YOU CAN BREAK YOUR PRINTER. USE AT YOUR OWN RISK. READ THE INSTRUCTIONS TO SEE MY HARDWARE SETUP BEFORE ATTEMPTING. Details and pics here:https://groups.google.com/forum/#!topic/makerbot/sDLkvrXNFK8 I have attached the vase STL for the pictured print because Thingiverse requires a model to be attached to Things, apparently. The original is here: http://www.thingiverse.com/thing:31722 Instructions PC requires printing temps that are WAY too hot for the stock R2x parts. PC should only printed with a high-temp setup, preferably all-metal. You can probably use the stock R2x hot end as long as the injection-molded carriage is replaced. IT WILL WARP from sustained high-temp printing. The stock Superstruder is a "maybe." If you keep your build chamber cool and do prints without a lot of retraction, you can probably stick with it. I used: Carl's T-shaped heater block, threaded thermal barrier, cooling bar, and aluminum dual carriage http://shop.raffle.ch/ DHeadrick's aluminum 3in1 extruder http://www.thingiverse.com/thing:136423 0.5mm nozzle from QU-BD (to get the nozzle viscosity down) Stock R2x heated build plate Basic print settings: 0.5mm layer width, 0.3mm layer height (bigger extruded threads provide better visual clarity and require less force to extrude) 265C nozzle temp 130C HBP temp, on UHU gluestick for good results. Poor results on 5 mil Kapton with ABS slurry. Bare Kapton or phenolic-type plates such as Garolite / G10 WILL NOT stick 30-60 mm/s print speed due to high PC viscosity and large nozzle (= higher plastic flow rate) PC warps worse than ABS because of the high glass point and high coefficient of thermal expansion. Parts should be designed with warping prevention in mind, just like large ABS prints. Tram close to the bed for good adhesion. Use skirts and helper discs on sharp corners, and reduce infill if you need to decrease warping stresses. Note that molten PC is very sticky and likes to gob up on the nozzle if you're over-extruding. Pull excess PC off the outside of the nozzle with tweezers immediately before printing. You should dial in your print settings using a 100% infill calibration cube. Get the filament diameter, feedstockMultiplier (packing density), and build plate adhesion sorted on the calibration cube before attempting any real prints. Otherwise you'll probably end up with a giant ball of indestructible plastic stuck to your nozzle. This stuff is STRONG and can't be conveniently dissolved by solvents like ABS can.

With this file you will be able to print MakerWare Profiles for Polycarbonate on an R2x with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on MakerWare Profiles for Polycarbonate on an R2x.