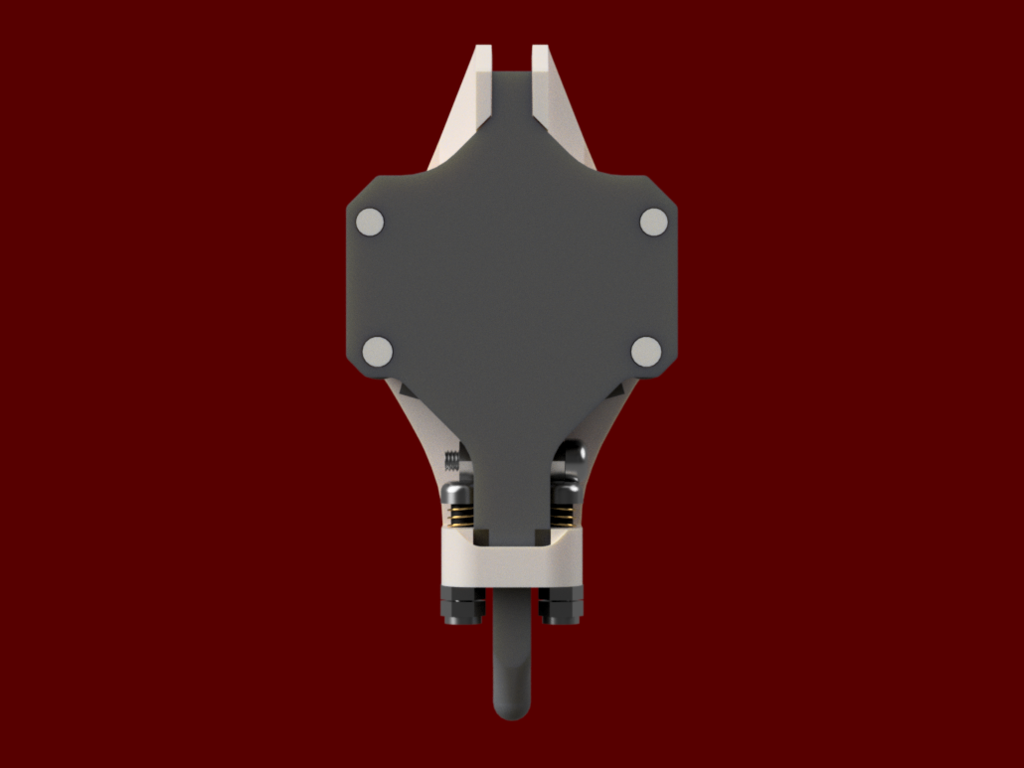

MechABL - An Affordable Auto Bed Levelling Sensor With an Automatic Retracting Probe

thingiverse

Part Counts: 1x Base 1x Plate 1x Probe 1x Mount 2x Probe Pin 2x Probe Arm 2x Base Arm 2x 4mm diameter 12mm long spring 2x 4mm diameter 2mm long spring 2x M3 Nyloc Nut 3x 16mm M3 Bolt 5x M3 Nut 8x 6mm diameter 3mm thick neodymium magnet (optional) MechABL is an affordable DIY auto bed levelling sensor with a mechanical retractable probe. I designed MechABL mainly because I needed an auto bed levelling sensor that could retract its probe automatically before every print because I had used other diy auto bed levelling sensors which most of them have to be manually retracted before the print starts and I have to admit it, I often forgot to rectract the probe and that caused many issues. MechABL avoids the problem of forgetting to retract the probe without any compromises to sensor accuracy. There are other automatically retracting sensors out there and most of them use a servo to retract and extend the probe. Using a servo for toggling the probe does sound great but there are many compromises made along the way such as: ⦁ Accuracy: Servos are not very accurate especially the cheaper and smaller ones. ⦁ Ease of installing: Hooking up a servo to a stock 3D printer board can be challenging and might require some irreversable modifications like cutting some wires. MechABL offers great accuracy while avoiding the problems mentioned above. The standart deviation of a MechABL sensor ranges in between 0.02 and 0.002 milimeters and installing a MechABL sensor is just as simple as replacing an endstop switch. MechABL is compatible with most BLTouch mounts. (I'm using an edited version of this thing: https://www.thingiverse.com/thing:3584158) There are 4 magnet pockets in the base and 4 magnet pockets in the mount. You need to pause the print before the printer prints over these pockets or if you don't want to use magnets you can glue the mount to the base. MechABL extends and retracts the probe by using a "snap motion mechanism". Basically the probe is always pushed in some direction because of two opposing springs. When the probe is primed and ready for triggering, two opposing springs constantly push it towards the buildplate. That helps the probe to be stable against some vibrations that otherwise could move the probe unpredictably. When it's time to retract the probe, nozzle starts coming closer to the build plate and the probe starts lifting up with respect to the nozzle. When the probe passes a point which the opposing springs push against eachother, the probe starts moving upwards because the opposing springs are now pushing it upwards and that causes the probe to retract before the nozzle hits the buildplate. Current MechABL design does not use a microswitch nor an optical sensor nor a hall sensor to sense when it hits the buildplate. It has an electrical pathway which gets disconnected when it hits the buildplate. That's what makes installing the sensor very easy. It only has two cables that are attached to the Z axis endstop switch pins and the polarization does not matter. Electronic noise can effect the standart deviation. Users are adviced to probe the buildplate while the heaters are not working.

With this file you will be able to print MechABL - An Affordable Auto Bed Levelling Sensor With an Automatic Retracting Probe with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on MechABL - An Affordable Auto Bed Levelling Sensor With an Automatic Retracting Probe.