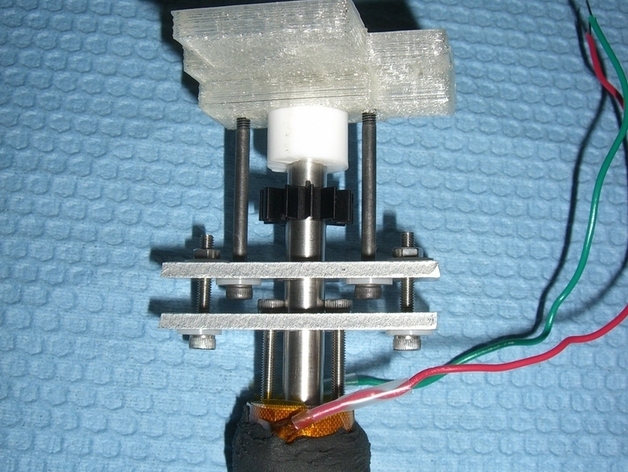

Mendel Custom Hot End (using some makerbot Mk5 hotend parts)

thingiverse

This design features a new hotend, inspired by Makerbot's MK5 extruder (http://www.thingiverse.com/thing:3290). It has a nicrome-wrapped cylindrical solid aluminum core that fits into a PTFE sleeve at the top, allowing it to be used with the original Mendel X carriage and compatible with the MOSFETs on the Mendel extruder controller board without requiring large clicky relays. The hotend utilizes the MK5 nozzle and thermal barrier tube available from Makerbot Industries storefront. The design doesn't include any printed parts, except for an optional extruder bottom piece. It uses various materials like Reprap Mendel extruder parts, nicrome wire on wires to wrap the heater core, a PTFE tube, 2024-T3 bare aluminum sheet/plate, 6262-T6511 extruded aluminum round rod, Makerbot Industries Mk5 nozzle, MBI Mk5 thermal barrier tube and PTFE core tube, a TO-5 heatsink, long and short M3 bolts and nuts, thermal fudge/epoxy or latex furnace/vent appliance sealant, and optional exterior insulation like ceramic. Instructions for assembly include drilling holes in the aluminum plates, drilling out connector holes on both plates, assembling and attaching the nozzle and barrier, affixing the thermistor, and finishing the plate assembly with a heat-sink. The PTFE core tube is inserted and cut to length, and an optional cap is fabricated for the upper end of the PTFE sleeve. Finally, the heater element can be wrapped in insulation for additional protection against radiant heat loss. Enjoy using this improved hotend design!

With this file you will be able to print Mendel Custom Hot End (using some makerbot Mk5 hotend parts) with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Mendel Custom Hot End (using some makerbot Mk5 hotend parts).