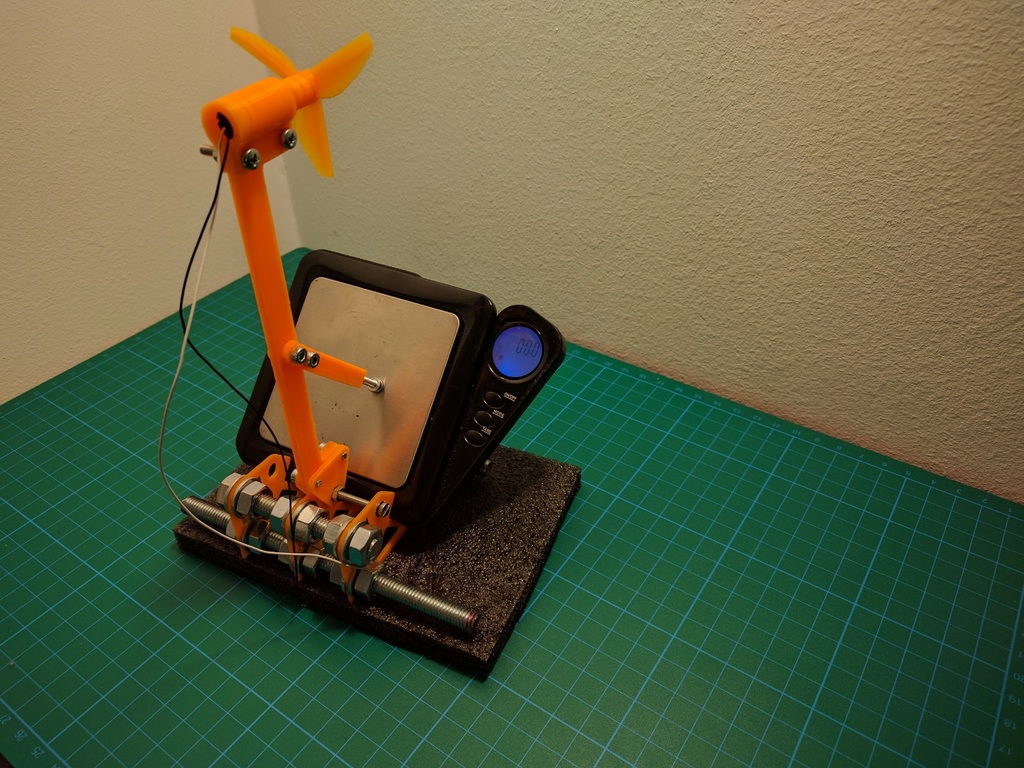

Micro Drone Propeller Thrust Testing Jig (8520 Coreless Motor)

thingiverse

This is a small test jig I made in order to measure the level of thrust generated by 3d-printed propellers. Check the pictures for a general idea of how the thing comes assembled. I used a few M8 bolts, washers and nuts to hold the main assembly. The smaller screws are all M3. The motor holder houses the [8520 coreless motor](http://amzn.to/2qPUhi4). At the base of the arm I used two [SMR63ZZ](http://amzn.to/2pTD8qC) bearings that allow the arm to pivot easily. The scale I use is from Kenex. It's an older model, but you can find the equivalent at this [link](http://amzn.to/2p6TnS2). When the thing is fully assembled, rest the arm with the long M3 screw (assembled on the "needle" part) on the scale and if the scale is on, simply hit "tare" before running any tests. Included you will find a few pictures of the final assembly, along with the STL files and SLDPRT files (in case you wish to modify the jig to suit your needs). The hub is where you can mount the propeller prototype. All you need to remember is to add a 3mm hole at the center of your propeller in order to secure it to the testing jig (I used an M3x10 screw for this purpose). You will need one of each part printed, aside from the main holder and the bearing holder. The bearing holder (triangle-like thing) should be printed in 2 copies. The large hole houses the small bearing and the other two holes secure it to the arm using M3 screws. The main holder should be printed in 3 copies. You can go for more for extra stability, but 3 should be the minimum copies for this assembly. I remember running into a few issues with the hub, so you should scale it up and down if you cannot install it on the motor shaft. This depends quite a bit on your printer and its cooling capabilities. The motor shaft is 1mm in diameter, so you'll need to play around with your settings to get the hub nice and snug. Once fully assembled, I recommend setting the whole thing on some vibration dampening surface. I used a piece of dark packaging foam which seems to hold well. Make sure the screws are tight in your assembly, since at higher RPMs the M8 nuts can come loose due to vibration. You can also use split washers or lock nuts.

With this file you will be able to print Micro Drone Propeller Thrust Testing Jig (8520 Coreless Motor) with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Micro Drone Propeller Thrust Testing Jig (8520 Coreless Motor).