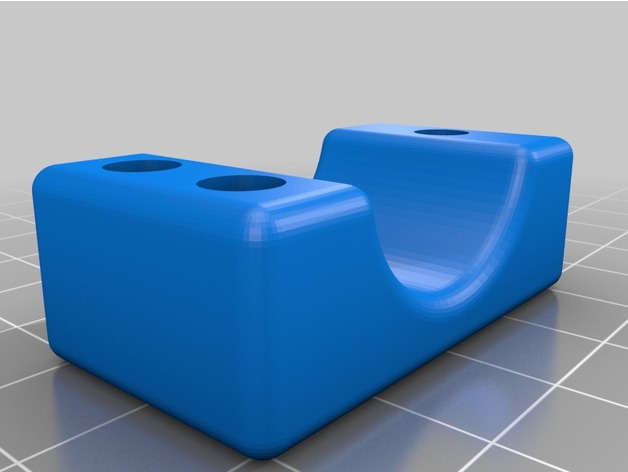

Midblade fork adapter (small)

thingiverse

Human: Emulates the functionality of:\nhttp://surlybikes.com/parts/all/front_mid_blade_mount_kit\nP-clamps\nU-bolts\nhttp://thetouringstore.com/thetouringstore/tubus-bicycle-racks-for-touring-and-commuting/tubus-fit-solutions/ "Tubus Aluminum Alloy Fork Mounting Kit"\nfor mounting front racks on forks that do not have eyelets in the middle of the fork length. These racks could be used for panniers, potentially.\nThe pieces are sensitive to compressive forces introduced by screws. Be careful. Remember that the lower eyelet on the forks (for fenders, etc.) should always be present & should take most of the load. This piece only prevents rotation about the wheel axis. It might bear some up/down load, but only as a bonus.\nThis is the small version for small-diameter forks. Think road forks. I have another version for much larger diameter mountain forks that has more features.\nUnless I get enough interest, I'm not going to apply these features to this smaller version. I'll explain the features in the post of the larger version.\nBonus: these might also work for rear racks if your seatstays are small enough. I might make a version of these explicitly for that purpose if I get enough interest.\nHow I Designed This\nWhy I think this design is better than the alternatives listed above (although I haven't tested all of them):\nThe Surly version is quick & easier to install, but lacks the security of nylon locknuts. This is a must for touring, unless you like retightening the bolts every so often & potentially losing hardware due to vibration.\nP-clamps: they're okay. Still would add inner tube shims to prevent paint rub-off.\nU-bolts: very secure, but very ugly & out of place. The ones that come with the Nashbar front rack are rubber-coated, but still rubbed off a lot of paint on my fork over 6300 miles or so. Add inner tube shims.\nThe Tubus version is slimmer & nicer in this regard (metal, so can use less material). But the through or blind hole in the center makes it impossible to use nylon locknuts (see Surly). If it's a through hole & the bolt is too long, you might unknowingly barrel the bolt straight into your fork. If it's a blind hole & the bolt is too long, you might bottom out & not know you don't have enough torque. I guess you could use red/blue Loctite threadlocker, but I'm a fan of permanent-until-you-don't-want-it-to-be solutions, like locknuts.\nAssembly & Materials\n1 piece has through-holes, the other has nut insets. The nutted piece goes on the inboard (wheel side) of the fork. Use nylon locknuts.\nUse fairly long 4 mm screws to attach. \nYou can add spacers on the outboard sides so that the pannier hooks don't gouge your fork's paint.\nUse inner tube shims to increase friction & provide a better custom fit.

With this file you will be able to print Midblade fork adapter (small) with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Midblade fork adapter (small).