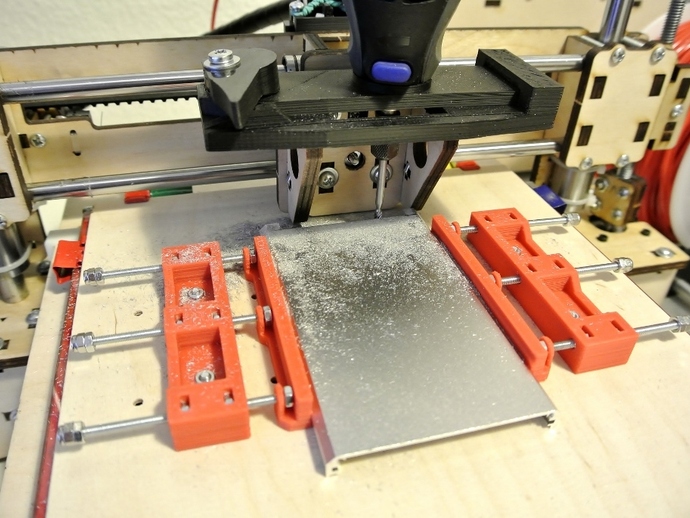

Milling Vise

thingiverse

An usefull helper for the first steps using my printrbot and dremel as a mil. I used the manual control buttons in pronterface. The result is good for the first try, but takes a long time. The dremel mount has some troubles with the forces during milling. I did the first round with a clearance of 0.5mm (the result was between ~0.2 and 1mm clearance). After that I removed 0.1mm per round only in order to keep the forces deep. Used tool: 3.2mm high speed cutter Instructions Assembly Print the needed parts Drill and countersink some holes in the base plate (the two holes in the block have a distance of 40mm) Push 12 nuts into the 2 blocks Prepare 6 nuts for the jaws (destroy the thread on one side of the nuts, so that the screw get stuck) Mount the vices as shown in the pictures BOM 2x printed blocks 2x printed jaws 1x base plate (plywood) 4x M3x10mm flat (countersink) head screws 22x M3 nuts 6x M3x60mm screws (or threaded bars with 6 nuts and 6 lock nuts as heads)

With this file you will be able to print Milling Vise with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Milling Vise.