Mini Lathe

thingiverse

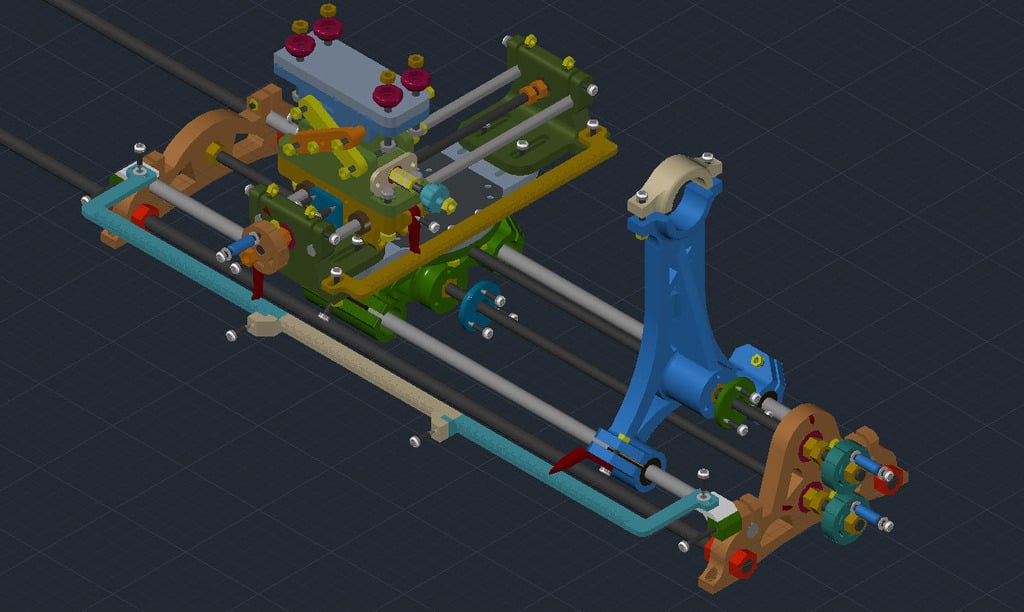

This is my Ver. 2.0. Four axis X0 and X1 for table and drill tool, Y and Z for tool holder. Rotatable table(every 15 degrees). 0.1 mm precision for X0, X1 and Y. With linear bearings for X0, X1 and Y. I will make updates regularly. Motor part will be for some el. drill at first or may be for permanent, will see (it is not ready yet). Probably I will change things on Z. All parts are printed with my homemade 3D printer. PLA 0.2 layer, 0.3 mm nozzle 25-30% infill. 12.08.2015. Printed the 2 ABS parts and made M4 nut holder(032 number part - for tool holder)/see last Autocad picture/. Reuploaded 023_TableBaseP3Left.stl - there was missing bed for X0 arrow. Needed things for assembly of Base, Drill tool and Table here: http://www.trendi3dprojects.net/lathe2_2.html 16.08.2015. After assembly of all Tool Holder parts, I saw a lot of instability and weakness. So parts 25, 26, 29 and 30 were reworked and reuploaded. Also added part 33. Needed things for assembly of reworked Tool Holder here: http://www.trendi3dprojects.net/lathe2_3.html Now it looks a lot better, but there is some backlash from LM6UU bearings... and none from LM8UUs. 17.08.2015. So, the backlash (axial along on the 6 mm smooth rods) with the tool holder is serious and part 27 will be reworked for 4 pieces of LM6UU bearings(instead of two). If this does not improve the situation, I'll remake it for LM8UU bearings. 19.08.2015. Part 27 for tool holder remaked and reuploaded. It is now for 4 LM6UU bearings for better stability. Extra 2 x M3 nuts and 2 x M3x12 mm bolts are needed for assembly of this part of the lathe. Reuploaded Autocad pictures with current updates. Added Autocad (Ver. 2010 or higher) file for laser cutting of heatshield of table - if the thing can manage, when ready, with soft metals - Aluminium, Copper, Brass. Added part #36 - 25 mm spacer for the wheel on X0 axis - it is still not very comfortable for rotation, but it is better than without it. Needed things for assembly of movement rods and wheels: http://www.trendi3dprojects.net/lathe2_4.html 24.08.2015. Updated with this thing: http://www.thingiverse.com/thing:624625 25.08.2015. Video with tests of wood, plastic, aluminium, steel, stainless steel - https://www.youtube.com/watch?v=4tGpBWL564o Results are a little bit disappointing. Have in mind, that I am with 3 LM6UU bearings(not 4), so there is still a lot of wobble and instability in Y/Z. I have ordered some, but they won't arrive soon. No such bearings here (just 8 mm or above). Also got a 1 mm mistakes in arms #2 (here they are fine), so now I am printing them again. One other thing - el. drill is not very suitable as motor, because of its hammer mode, relatively to that - axial movement of its drill holder. So after fixing these issues I will give it second chance. If results are similar it will be left for wood and plastic and will use it as base for next one in the future. Uploaded drafts for Autocad 2010 or higher version.

With this file you will be able to print Mini Lathe with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Mini Lathe .