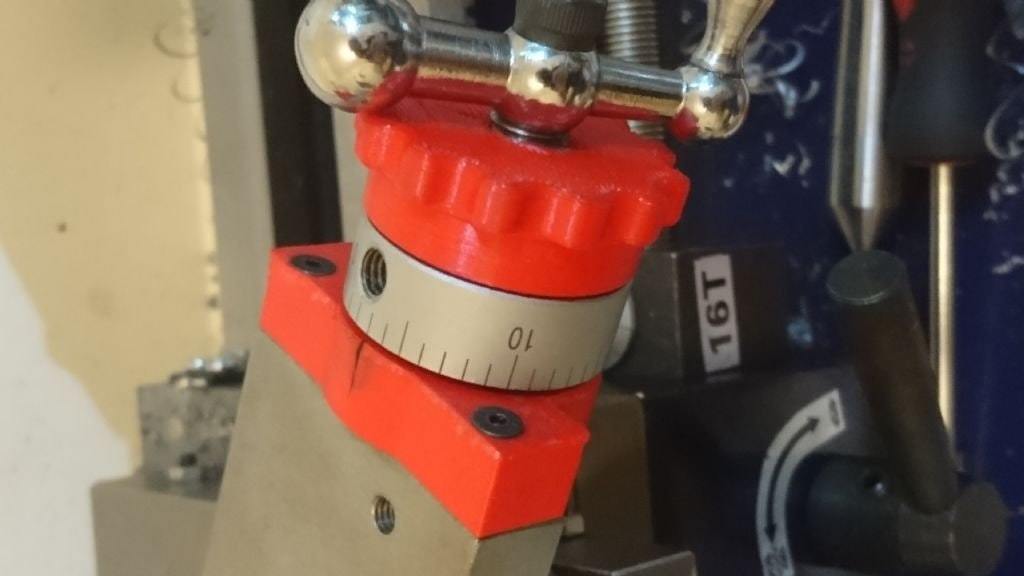

Mini lathe compound bearing upgrade

thingiverse

Made for my CJ18A minilathe, will probably fit most asian 7" swing machines. The dial lock will require a M10 thread being tapper through the bore. Using a countersink to chamfer the ends really helps to keep the tap true. You also need to drill and tap two M3 holes, about 10mm deep. 39mm apart and 3.5mm down from the top of the compound slide upper, hole should be 5mm from the edges of the compound. There is also a drilling jig to help you line your holes up, works best in a drill press (a drill can wobble and will chew up the jig but it can last long enough to give you a lil crater to start free hand drilling into) The thrust bracket takes a 6900 ball bearing and is designed to be a light press fit. I held the bracket against the closed chuck jaws and used the tailstock to push the bearing in. You could use a vice or a hammer (gently). A thrust bearing is put under the Dial lock so it can be tightened without transmitting the rotation to the dial. On ebay it was an AXK thrust bearing 10x24x4. The bush goes between the bearing and the dial. I think you could make this on literally any printer. No part is large or very complicated. I made mine out of PLA for lack of options (no heated bed). Ultimately I will recreate this is steel cos y'know thats what a lathe is for.

With this file you will be able to print Mini lathe compound bearing upgrade with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Mini lathe compound bearing upgrade.