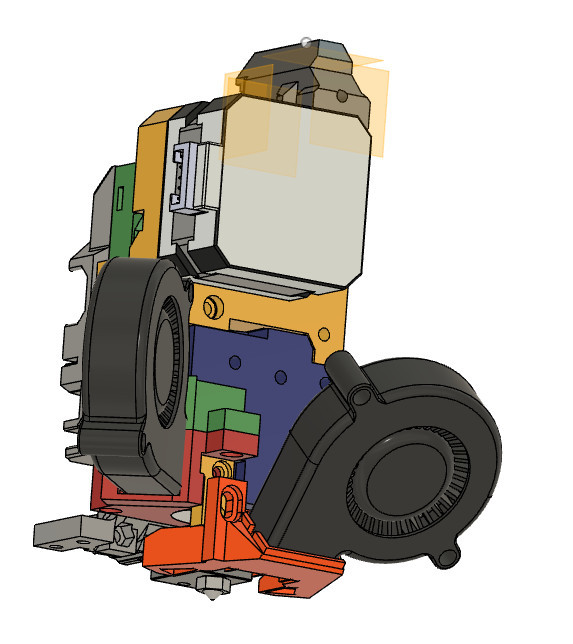

MK2.5S MK3S Extruder

thingiverse

First, I did use some other parts found here on Thingiverse. They are mentioned in the attached PDF. Why a new extruder? There were a couple of reasons. First, I wanted to have a project to improve my skills with Fusion 360. I didn’t want it to be too easy, so I chose for an extruder for my Prusa MK2.5s and MK3s. Both where equipped with a Bondtech BMG. Second, just for fun to see if I could do it and third, why not. When you start designing you set some goals. • Make it compatible with the stock Prusa firmware. So, no change in Z height. Not depending on community firmware. • Everything accessible from the front. Only body attached to X-carriage. Everything can be removed from the frontside. • Using the 3:1 gearing from Bondtech. I already have them so why not use them. • Make it compatible with the MMU2s. Filament sensor triggered by the extruder gear door. • Extruder gear door removable with one screw. Not disassembling anything else. • Removing hot end without disassembling most of the extruder. Only turn away the nozzle fan and remove the hot end clamp with two screws. Hot end wiring through separate sleeve. Optional connector on electronics cabinet to remove complete hot end with sleeve. Sleeve is connected to master sleeve with Velcro. • Separate bottom part that can be removed when damaged. Only this part needs to be heat resistant. • Nozzle fan a little bit height adjustable when its cooling the heat block too much. • Cooling the heatsink with a radial fan. • Use with the Revised X-axis by Vekoj. I adapted the X-carriage so it can be used on the MK2.5 and the MK3. • Fixation screw for the heatsink. No Rotation. • Possibility to remove square nuts (punching hole from the other side). • No screws directly in plastic. Always use a nut. • Motor axis gear visible to see its rotation. • Mounting place for optional Led Lights. Well, I succeeded, learned a lot while doing it. Not only Fusion 360, but also making design decisions about printability and ease off assembly. The first prototype is running on my MK2.5s Without problems. I installed the most recent original Prusa firmware, 3.8.1 and ran the XYZ calibration. Passed the first time. More in the attached PDF

With this file you will be able to print MK2.5S MK3S Extruder with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on MK2.5S MK3S Extruder .