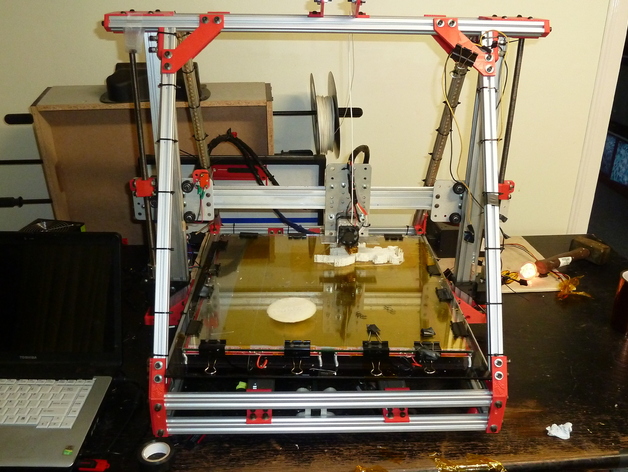

MMaxislider 3d printer Reprap

thingiverse

I initially wanted to buy a 3d printer but was not happy with the size so i decided to create and build my own design based on the best of what was out there. This is a large 3d printer with a print area or build size of approximatly 22" x 16" x 15"or 560mm x 410 x 380mm. It uses Makerslide linear bearing system http://www.makerslide.com/ for the x, y and z axis. It is a derivative of the Mendelmax and the Quantum Ordbot. I am currently building a prototype. The build is scalable and it is easy to expand the model just like its predecessor the Mendelmax. send me an email on jjimmijj@tpg.com.au FEATURES: Large build area 22" x 16" x 15"or 560mm x 410 x 380mm Aluminium extrusion frame Makerslide linear V/ rail x,y & z axes Adjustable belts 12mm threaded rod Easy assembly Scaleable Solid build No extruding parts Self replicating Reprap I have utilised several ideas from thingiverse in this build and would like to thank the following for their ideas and inspiration.... Mendelmax by Kludgineer http://www.thingiverse.com/thing:12645 Ord Bot by bdringhttp://www.thingiverse.com/search?q=ord+bot MendelMax - Adjustable foot - round by NM-Buzzardhttp://www.thingiverse.com/thing:15880 Dual Makerslide y-axis by simonious http://www.thingiverse.com/thing:15884 Spool Holder by kludgineerhttp://www.thingiverse.com/thing:13329 prusa y-axis belt tensioner by chrillehttp://www.thingiverse.com/thing:10274 Instructions UPDATE 4/9/12 Everything is printing fine, been having good results. have uploaded new sideclamp part (stronger) and alternative nema 23 stepper motor mount(too much play in the original.the only thing i have left to figure out is how to run four standard heat beds off one computer power supply, as at the moment i am only able to heat 1/4 of the build surface area . Any tips? Will upload new video soonish maybe today and show some of the things i have printed. One thing i havent been able to work out and i think is an issue with the printrboard is that i have to pull out the Y-axis end stop plug from the printrboard in order to connect to pronterface i saw on a forum that this may have been identified as a fault on some boards.Not a big issue it just means that i have to manually position the y -axis before starting a print, i am now using "cura" as my slicing program as it seems to be able to slice more complicated parts than slic3r and for a big build area you need a slicer that can handle the job.Thinking of a kickstarter project depending on demand.Oh and check out the new model i uploaded which is printing ATM. I am thinking of designing an alternative spool holder.Oh and i didnt end up using the ABS sidebracketforextruder part. UPDATE 7/12/12 All the parts eventually arrived and after a rather steep learning curve with the printrboard, marlin arduino pronterface slic3r i managed to get things printing still have a few teething problems i am going to upgrade the extruder to a makergear plastruder and need more power to power all the heat beds at once, ill update next when i get a perfect print./ http://www.youtube.com/watch?v=J-g_ZVq_EJE&feature=youtu.be UPDATE 25/3 I have reuploaded all of the files theY should now be all to scale. I have included smaller versions of some of the parts to enable them to be easier to print As well as plates of the parts to print which i have designed for a build plate area of 20 x 20 cm. Let me know if there are any problems with any of the files. Some parts have arrived, i am still waiting on the Makerslide and i still need to get the parts printed .......... Here is a list of the components from the Makerslide store http://store.makerslide.com/ with prices ( as at 8/3/2012.) MakerSlide(total3100mm) 600mm x 3, 650mm x 2,$0.011mm = $34.10 Dual Bearing V Wheel Kit (16) $2.85ea = $45.60 Eccentric Spacer (5) $2ea =$10 MXL Belt Open Ended, 0.250 Wide (10 feet) $2.40' = $24 NEMA 17, 0.9°, Dual Shaft (4) $22ea = $88 Pulley, MXL 18 Tooth, 0.250" bore, Dual Flange 1= $5.50 Pulley, MXL 18 Tooth, 5mm bore, Dual Flange 1= $5.50 Smooth Idler Wheel Kit (2) $4.75ea =$9.50 Spacer, Nylon .192 ID, .312 OD, .250 Lg. (6) $0.20ea = $1.20 Spacer, Nylon .192 ID, .375 OD, .125 Lg. (4) $0.30ea = $1.20 Spacer, Nylon .192 ID, .375 OD, .875Lg. (8) $0.35 = $2.80 Standard Wheel Carriage Plate (5) $8ea = $40 Total cost of makerslide components (not including postage)=$267.40 Total cost of other components not including electronics, heat beds, extruder and plates = $465 So i suppose if you throw in postage your looking at somerthing like $740- probably around $1200 for a complete build. These are the rest of the components minus the plate/s, extruder and electronics(includes microswitches). Part codes in this list come from the misumi website http://sg.misumi-ec.com/ just enter the part number in the search box for more details,of parts. The below list is not accurate and supplies more parts than needed. Look to the step file model for guidance. 1 nema 23 motor $36 3 microswitch standard 2.5 $7.5 2 motor coupling 12mm -5mm 9 $18 2 12mm stainless teel threaded rod 1.75 18.26 $36.54 2 Hex Nut 12MM 1.75 stainless steel 1.35 $2.7 16 Hex Nut 3MM 0.66 10.56 BOX-LBNR3 65 Hex Nut 5mm 0.45 29.25 BOX-LBNR5 $20.86-32.08 4 Hex Bolt M5 x 0.8 x 16 1.44 5.76 rcb5-15 6 Hex Bolt M5 x 0.8 x 20 1.44 8.64 RCB5-20 10 Hex Bolt M5 x 0.8 x 30 1.6 16 RCB5-30 10 Hex Jam Nut thin nut 5mm 0.16 1.6 PACK-SNTRCS5 25 Metric Plain Washers m3 0.19 4.75 NLDF3 40 Metric Plain Washers small 5mm id 8- 10mm od 0.19 7.6 NLDF5 200 Metric Plain Washers 5mm id 15mm od 0.11 22 pwf5 37 Forged Socket Head Cap Screw - Metric M5x0.8 x 10 0.14 5.18 CB5-10 154 Forged Socket Head Cap Screw - Metric M5x0.8 x 12 0.14 21.56 CB5-12 4 Forged Socket Head Cap Screw - Metric M5x0.8 x 16 0.14 0.56 CB5-16 4 Forged Socket Head Cap Screw - Metric M5x0.8 x 20 0.14 0.56 CB5-20 32 Forged Socket Head Cap Screw - Metric M5x0.8 x 25 0.06 1.92 CB5-25 10 Forged Socket Head Cap Screw - Metric M5x0.8 x 35 0.18 1.8 CB5-35 4 Forged Socket Head Cap Screw - Metric M5x0.8 x 40 0.19 0.76 CB5-40 20 Forged Hexagon Socket Button Head Cap Screw - M5 x 0.8 x 30 0.72 14.4 BCB5-30 4 bearing 5mm id 16mm od 5mm wide 1.28 5.12 B625ZZ 4 Forged Socket Head Cap Screw - MetricM5 x 60 0.27 1.08 CB5-60 10 Slotted Pan Head Screw Low Head Cap Screws - Standard M5 x 10 1.04 10.4 CBSH5-10 2 Deep groove ball bearings 12mm id 28od 8 mm wide 2.09 4.18 C6001ZZ 12 Hexagon head thread forming screws TATRS5-12 SELF TAPPING M5 x 12 1.47 17.64 TATRS5-12 8 Slotted pan nead screws M3 x 16 0.41 3.28 BCB3-15 6 Cross recessed cheese head screws M3 x 35 0.72 4.32 ?? 200 tslot nut for 2020 extrusion 0.023 44.92 What size? 2.2 aluminium extrusion 6.18 13.596 HFSB5-2020-550 black anodised 2.32 aluminium extrusion 6.18 14.3376 HFSB5-2020-580 2.64 aluminium extrusion 6.18 16.3152 HFSB5-2020-660 1.468 aluminium extrusion 6.18 9.07224 HFSB5-2020-735 extruded components from 8020 Australia http://www.8020.com.au/ will cost $203.69 delivered ). Avg cost of extrusion including postage, GST and cutting is $0.024 per mm(2020 extrusion.) T-nuts %0.20-%0.50.

With this file you will be able to print MMaxislider 3d printer Reprap with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on MMaxislider 3d printer Reprap.