modular casing for small things you have made

thingiverse

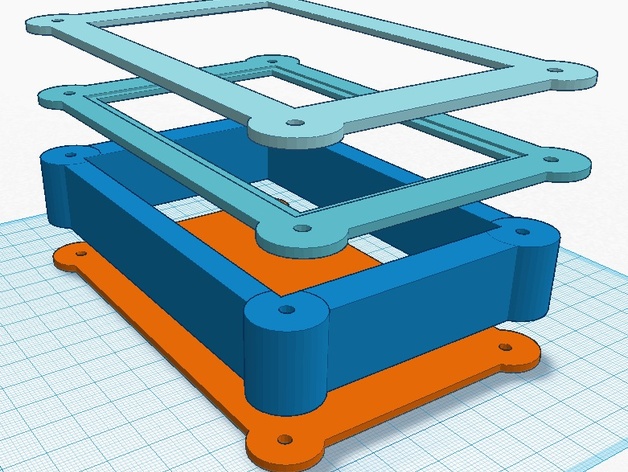

Reusable Modular Parts for Enclosures Create custom cases without buying a new one for each project Exchange board, print new case - Too much waste of time, effort and material Reuse modularized system components: cylinders, plates, frames (with/without top/bottom planes) Make gadget using parts from this project or remixed projectbox Combine things as you like, make it mobile with the additional extenderbox Files Update: added ballhook- and latch- pictures Latched mounted on printed lids without latch; frame with counterpart required Added some ballhooks, smal hook with mountplate, hinged lid V3R3 (See gift box remix) Components: - Bottom part (carrier for pcb exposer or carrier for a thin-flat battery and a pcb) - Top frame windowed (carrier for plate made from glass or other materials with 2mm thickness) - Solid top/bottom plate 2mm thick - Intermediate frame 2mm thick, cutout 66x105mm - Intermediate frame 5mm thick, cutout 66x105mm - Intermediate frame 10mm thick, cutout 66x105mm - Intermediate frame 20mm thick, cutout 66x105mm - Nutcaps (same shape as the roundings) - Frames 4mm with slot for slides 60x100x2mm (top/side entry) - Frame 3mm with slot for slides 110x74x1mm - Basemodul 20mm (was extenderbox) - Open frame 20mm with support for plates/pcb (was for pcb 60x100mm) - Supportwall 70x100x5x5mm - Supportwall 70x106x5x5mm - Supportwall 70x106x5mm - Supportwall 60x100x5x5mm - New openframe 20mm (cave 70x106mm) - Basemodul with increased cave (70x106mm) with supportwall - Thumbwheels 14mm OD M3, thumbwheels 16mm OD M3 Todo: Frames/top covers with flange/collar resembling small orange bricks Try to make them stackable without screws where possible: if it doesn't sacrifice too much room and fit is tight enough to hold the things together

With this file you will be able to print modular casing for small things you have made with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on modular casing for small things you have made.