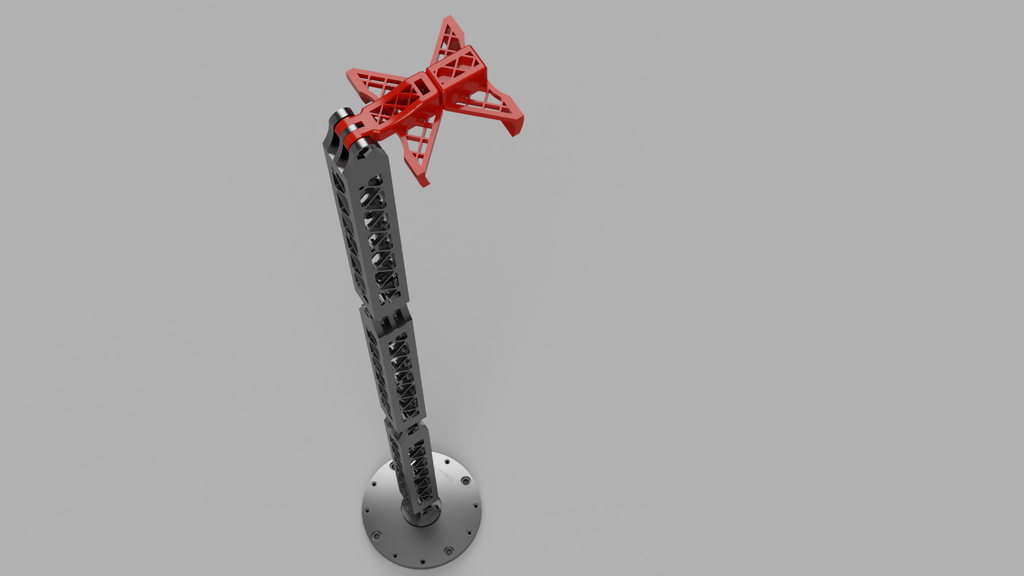

Modular Phone Holder and Arm

thingiverse

This is a modular girder system to put an extendable, adjustable phone holder arm onto your table. You can build 1-3 (haven't tested more, but three is already flexing much) sections of girders to assemble a joints system. Highly suggested to use *PETG* for everything except base table plate - PETG is more resistant to bending and isn't slippery (especially important for joints), and ABS is slippery and helps making the rotating table plate part easier to turn. Instructions for 3 sections long arm: * using **ABS**, print all three `rotating table plate - *.stl` parts * 60% infill (can do less, but this is what holds everything in place when arm is fully extended and you put a big phone in it!) * using **PETG**, print the swing joints @ 100% infill (these receive lots of load, especially when you want to torque them down to stop slippage - you want them full of material) * 4 x `swing joint - female side.stl` * 3 x `adapter.stl` - this is what you put the hex nuts in, bolt to the girder, and then you can bolt the male joint on it * 3 x `swing joint - male side.stl` * 1 x `phone holder - bottom.stl` - PETG is important here because the parts that press against phone will bend, you don't want them crack * 1 x `phone holder - top.stl` - PETG is important here because the parts that press against phone will bend, you don't want them crack * using **ABS, PLA or PETG** (I used PETG - less brittle, but ABS worked for one of the sections, too) print: * 12 x `girder plate.stl` - 100%-20% infill all will work - since the parts are very small, it doesn't make much difference in plastic consumption nor printing time Other hardware: * a pile of M3 bolts in lengths of 8, 10 and 12 mm + M3 nuts. * 4 x M6x30 bolts + nuts for joints * M6x40 bolt + nut for phone holder * based on where you want to attach this contraption to, you can use screws or bolts up to M6 to attach table plate on. Ideas - wall, table, one of the enclosure sides. Other notes: * printing temperatures - according to your preferences for specific materials. I use: * ABS - 240ºC nozzle, 110ºC bed, enclosed * PETG - 235ºC nozzle, 80ºC bed, preferably enclosed * layer sizes - 0.2 is what I chose, others could be possible but I prefer smaller ones as there are relatively many small details in those designs. * materials - ABS could also be glued together for additional strength using acetone * post processing - haven't tried but I think this thing should benefit from annealing (optional) * I believe these things, as they do serve structurally and do not require much dimensional accuracy * after that they can be drilled to size if necessary * different parts should deform evenly if treated together, so they'll still match

With this file you will be able to print Modular Phone Holder and Arm with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Modular Phone Holder and Arm.