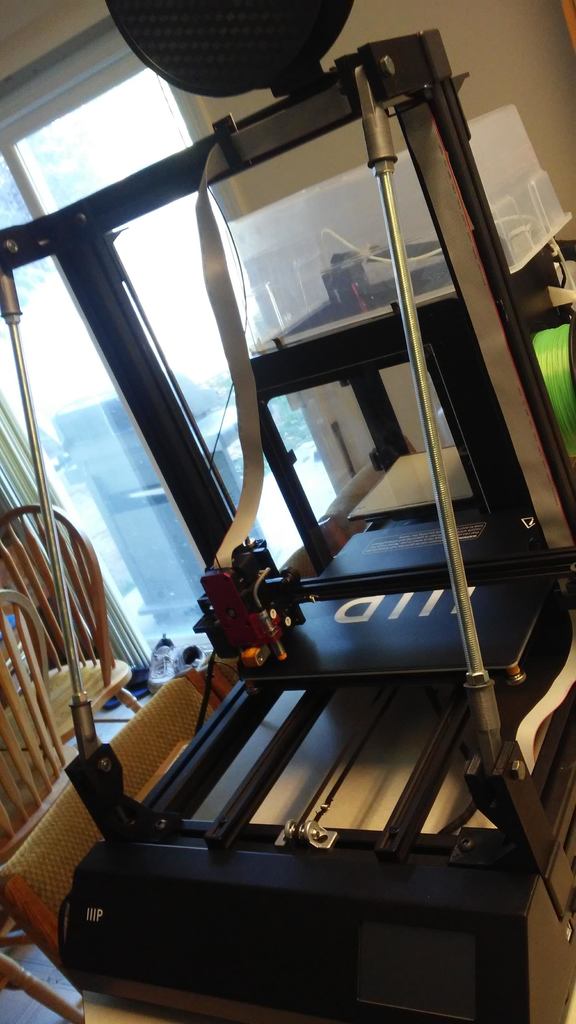

Monoprice Maker Pro Mk. 1 / Wanhao Duplicator 9 Gantry/ Z-axis Support Braces

thingiverse

Monoprice Pro Mk. 1 / Wanhao Duplicator 9 Gantry/Z-axis Support Braces I know that Wanhao once offered their braces for the Duplicator 9 at a price of $30, but this offer has expired and they now want $60 for them. These brackets securely fasten the vertical axis of the printer from vibration and possible deflection. This is a straightforward z-axis brace that should cost less than $20. All in, with filament and hardware, it cost me under $15. I designed the brackets to match the 1.5" 8020 aluminum extrusion, be in-line with the gantry frame and still allow enough clearance for the moving parts of the printer. The first iteration were long brackets but after printing one and mounting it, I redesigned it to shorter versions which work well. I used the short versions on both the frame and gantry so, essentially you print all (4) short brackets and it will work fine. In any case, this is not meant to be a final version and there are many ways that it could be tweaked. Since the Mk. 1 uses standard 80/20 aluminum 15 series (1515) extrusion for the frame and gantry it's easy to add braces as well as other things. I simply made 1.5" brackets that bolt to the gantry and frame using 5/16" t-slot hardware. I had the t-slot hardware already but don't worry about it if you don't have it because there are many ways to connect to the t-slots on the aluminum extrusion. I've included pictures that show how to mount the bracket (as well as other things) using common carriage bolts in the extrusion t-slot. I printed the brackets vertically at .2 resolution with a 1.6mm shell and 50% infill. The bracket connects to 3/8"-16 threaded rod via the pivot connectors. As designed, the pivot connectors will need to be tapped to accept the 3/8" -16 threaded rod. You could probably work the threaded rod into the connectors hole with some patience without the use of a tap. The design has a deep hole which accepts over an inch of the threaded rod which helps to stiffen up the pivot connectors. I printed the pivot connectors vertically at .2 resolution with 1.6mm shell and 100% infill. Hardware list ~$10-$15: * (2) 18" long 3/8" -16 threaded rod (purchased 3' length and cut in half) * (4) 3/8" washers (for threaded rod) * (4) 3/8" -16 hex nuts (for threaded rod) * (8) 5/16" -18 button head socket screws 5/8" length OR 5/16" -18 carriage bolts 1" length (for bracket to frame/gantry) * (8) 5/16" -18 slide-in t-nuts OR 5/16" -18 hex nuts (for bracket to frame/gantry) * (4) 5/16"-18 hex bolts 1.5" length (for bracket to pivot connection) * (4) 5/16 -18 hex nuts (for bracket to pivot connection) Tool list: * 3/8" -16 tap * Hacksaw or some other tool to cut threaded rod into ~18" lengths * 1/2" sockets and wrenches * 9/16" open wrench * Allen wrench if using socket screws and sliding t-nuts

With this file you will be able to print Monoprice Maker Pro Mk. 1 / Wanhao Duplicator 9 Gantry/ Z-axis Support Braces with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Monoprice Maker Pro Mk. 1 / Wanhao Duplicator 9 Gantry/ Z-axis Support Braces.