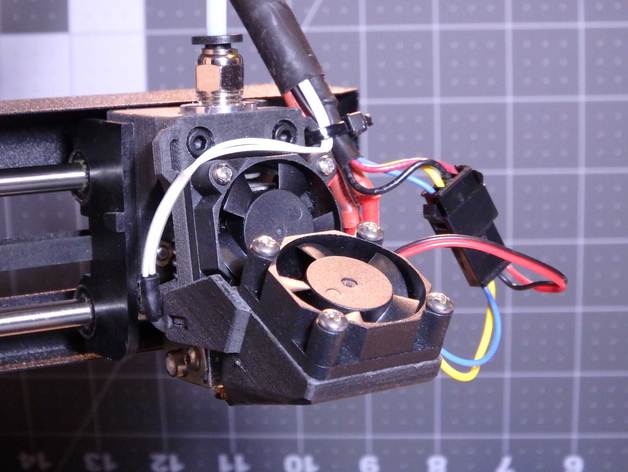

Monoprice Select Mini E3Dv6 Zero Offset Mount

thingiverse

This collection of things combines to form an E3Dv6 Hotend mount for the Monoprice Select Mini (Malyan M200) 3D Printer. These parts were created as part of our ongoing project to maximize the performance of the Monoprice Select Mini Printer. You can read about our other mods on our Hackaday.io page located here: https://hackaday.io/project/14823-monoprice-select-mini-maximum-3d-printer-mods The differences between this mounting adapter and others you may have seen are: 1) The nozzle XY position is almost exactly the same as the stock hot end, making it easier to install. 2) The bracket is designed to be adjustable, allowing for a perfect fit on any printer. 3) The E3Dv6 hotend is designed to work with the Mini's 12V power supply, eliminating the need for a separate power source. To install the E3Dv6 Hotend Mount, follow these steps: 1. Remove the stock hot end from your printer and set it aside. 2. Install the bracket onto the carriage using M3 cap screws. Make sure to secure it tightly to prevent any movement during use. 3. Slide the E3Dv6 hotend through the hole in the base of the clamp and attach it to the bracket on the carriage using M3 cap screws. 4. Connect the hot end cooling fan to the bracket, making sure it's securely attached. 5. Install the part cooling fan onto the bracket, making sure it's aligned properly with the slots on either side. 6. Connect the JST connector to the controller board and configure the firmware to control the speed of the part cooling fan. The optional part cooling fan really needs to be speed controlled for the best prints, so make sure to connect it to a separate power source or use a PWM controller. Here's a short video clip of the Zero Offset E3Dv6 Hot End Mount in action.

With this file you will be able to print Monoprice Select Mini E3Dv6 Zero Offset Mount with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Monoprice Select Mini E3Dv6 Zero Offset Mount.