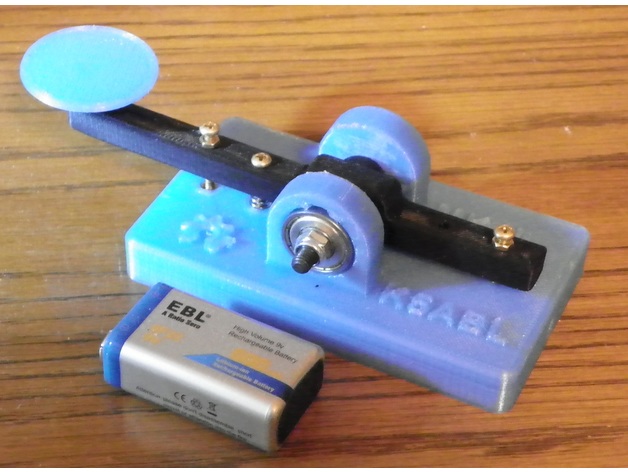

Morse Code Straight Key

thingiverse

Update 4/17/17 - I've added a center beam made of non-conductive plastic, eliminating the countersinks for threaded inserts. The conductive plastic design has been tweaked to slightly reduce the threaded insert countersink. This was necessary because some inserts were loose after cleanup. This design is inspired by NA8E's morse code key found on Thingiverse under ID 630117. I created this project from scratch in Solidworks, going through four to five versions before settling on this one. Similar to the NA8E key, this one uses bearings and a precision-fit shoulder bolt to support the main beam for smooth operation. All brass hardware is used, including 4-40 components and brass inserts for the plastic parts to prevent stripping or pulling out. The center beam can be printed from conductive plastic to make connections to the top contact at the rear of the beam. It also features gap adjust and spring tension adjust. The necessary hardware includes: * 2 x 686-ZZ bearings, 13mm OD, 6mm ID, 5mm thick * 1 x 6mm dia x 45mm shoulder bolt * 1 x M5 x 0.8 nylon insert nut (McMaster 90576A104) * 4 x 4-40 narrow brass hex nuts (McMaster 95130A110) * 3 x screw to expand brass inserts for 4-40 (McMaster 92395A315) * 1 x 4-40 round head brass 5/16" screw (McMaster 94070A107) * 1 x 4-40 round head brass 5/8" screw (McMaster 94070A112) * 2 x 4-40 round head brass 1" screws (McMaster 94070A115) Please check my personal site, K5ABL.com, for availability of printed keys, customized keys with call sign, and hardware kits. Print Settings: * Printer Brand: Rostock * Printer: Rostock MAX V2 * Rafts: No * Supports: Yes * Resolution: .4mm nozzle, 0.2 or 0.25mm layer * Infill: 70% * Notes: + Base - 1.75mm PETG @ 260C + Beam - 1.75mm PETG @ 260C or ProtoPasta Conductive PLA @ 220C + Print speed: 35mm/sec + Supports only on base, touching build plate only Post-Printing: * Support will need to be removed under the base. * Cross holes on base and beam for shoulder bolt will need to be cleaned up. * Recesses for bearings will need to be cleaned up. Bearings should be a firm press fit and run the shoulder bolt through bearings before assembling to align bearings. * Inside of bearing supports and center beam where it contacts support will need to be filed/sanded just to smooth, without removing material that would cause unwanted side play. * A Pilot G-2 Pen or similar spring will need to be sacrificed for its spring. * Beam recesses for brass inserts need to be cleaned up only; do not enlarge them, as the inserts will not grip. How I Designed This: This project was designed in Solidworks 2012. Files are provided in parasolid format for better portability.

With this file you will be able to print Morse Code Straight Key with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Morse Code Straight Key.