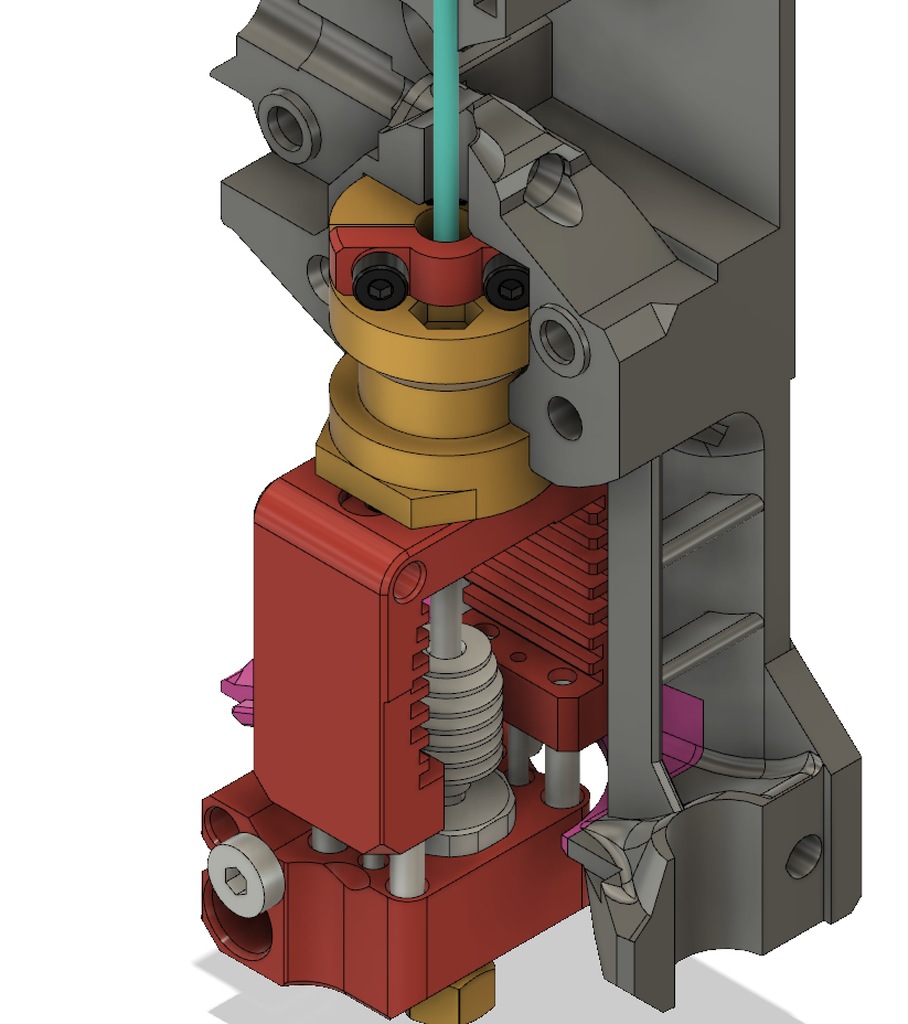

Mosquito Compatibility Kit for BNB MK3S & MK3 Extruders

thingiverse

To obtain most current files, please individually download the ones you need. - This kit is primarily for the Bunny and Bear "Short Ears" extruders... BNBSX Short Ears MK3S Extruder for main instructions and https://www.thingiverse.com/thing:3626993 or Bunny and Bear Short Ears MK3 Extruder https://www.thingiverse.com/thing:3606189 This kit has E3D style groove mount adapter and hot fins to use Mosquito hot end with either Short Ears extruder. Extruder must be version B02M3 or later to accept the adapter this kit. Older version extruders will not accept this kit. Because Mosquito heat sink is wider than the E3DV6. Bunnies enlarged air plenums of the Short Ears extruders to accommodate the Mosquito, but keep E3DV6 airflow optimized via removable panes. Bunny Science Short Ears extruders have a special shaped hot end cover that engages with the adapters and spacer of this kit to give the mount anti-rotation feature. You perform Mosquito style, one-hand nozzle change with this kit and a Bunny Science extruder. Square shouldered groove adapter in kit can also be used with other extruders, provided they have wide enough air plenum. However, non-Bunny Science extruders will lack the anti-rotation feature of this kit. Omit the E3DV6 panes and hot fins from your Short Ears extruder. Install mosquito specific hot fins from this kit. E3DV6 Plenum panes are not used with Mosquito. They are removed to make space for the Mosquito. Orient the anti-rotation flat of groove adapter or spacer faces forward to engage hot end cover! Mosquito attaches to adapter in this kit via two M2.5 x 16 mm screws and nuts. PTFE clamp uses 2 M2 x 6 mm screws Air flow plenum wall is quite thin when E3D plenum is removed. Please verify middle M3 x 8mm screw attaching extruder to x-carriage does not impinge Mosquito heat sink. --- PTFE tube from Mosquito should be 27.5 mm on BNBSX MK3S PTFE tube from Mosquito should be 33.5 mm on BNB Short Ears MK3 Cut slightly longer than spec and trim after checking against your actual extruder build. PTFE ends are to be cut square on both ends. You can use one of the groove adapter as convenient square cut tome. Slide PTFE tubing to cut position then briskly slide blade along flat surface of PTFE. A quick cut produces a more square result than a slow pass. Bondtech end of PTFE should be interior chamfered by hand rotating a medium sized drill bit. Clear away all cuttings! Be certain no PTFE debris gets into extruder. Two versions of the groove mount adapter are provided. The one with chamfering at top of its waist prints cleanly without supports. However, it will ONLY fit Short Ears extruders. The version with 90 degree overhang at top of its waist must be printed with supports. Its advantage is it can be used with non-Short Ears extruders (provided air plenums are wide enough for a Mosquito) Both versions are plated in the 3mf. --- Alternatively, use the nicely machined, aluminum groove mount coupling from Printed Solid. https://www.printedsolid.com/products/groove-mount-coupling-with-tapped-holes-for-slice-engineering-mosquito-hotend The aluminum PS coupling includes usual E3D clamping mechanism. Add kit's 3 mm spacer and use longer M2.5 screws when using the Printed Solid groove adapter. The 3mm spacer is needed to position Mosquito nozzle to pass Prusa XYZ calibration. The spacer has a top and bottom. Orient 3mm spacer so its anti-rotation flat is at bottom of the spacer. The top of the spacer should have about 0.5 mm without the flats. - Mosquito Hot End Notes The Mosquito, with its exposed heater cartridge position and short melt zone, is exquisitely sensitive to both noctua and print cooling fan airflow. It massively loses heat if cooling air strikes it or print nozzle. With the BNRHD's ample, two sided cooling airflow, bunnies got horrible, crumbly, under-heated extrusions even with nozzle temperature increased by 15C and print fan cooling so far down that overhangs failed. Black PETG would extrude as milky, dark gray instead of its usual black, glassy appearance. *USE A SILICONE HEAT SOCK WITH THE MOSQUITO and the Short Ears extruders. The extra insulation can be the difference between good function at usual temperature and fan settings vs unusable results. As a plus, the sock also prevents filament sticking to the mosquito body. See https://www.thingiverse.com/thing:3562134/remixes http://www.thingiverse.com/thing:3562134 Mosquito Hotend Sock Form by sadkins1981 Bunnies rank the silicone sock as essential to success particularly if using a 40 watt cartridge. A 50 watt cartridge may be helpful, but a silicone sock works wonders combined with brass nozzles. If you use the Slice vanadium nozzle, be aware its thermal conductivity is far less than that of a brass nozzle. Expect to raise nozzle temperature 20-30C to achieve barely equivalent filament behavior as with brass nozzle. Bunnies have great success getting Mosquito to print at near normal temperatures by using Spool3D's tungsten carbide nozzle instead of hardened steel (Slice Vanadium, E3D NozzleX, etc). Tungsten carbide (not to be confused with tungsten alloy!) has best of both worlds brass-like thermal conductivity and super hardness. - General Notes As of B03M1, fan shrouds and hotend hot fin now interlock via an "Evan" hook. Install shrouds by engaging hook first and then inserting mounting screw. Fan shroud installation is easier with print fan screws loosened. Elephant footing or excessively low Live-Z may reduce bore diameters at bottom of prints. Use drill bit to clear out bores to correct size. Due to unavoidable tight spacing, there are open slots in the groove adapter. The slots do not affect functionality. Don't go crazy tightening the PTFE clamp. Just get it snug. Users were had difficulty finding a fan shroud that will fit asymmetrically wide Mosquito hot end. A wider shroud was remixed from RHD air nozzle for kit. Use Nylock nut to mount fan shroud rather than regular M3 hex nut. Wider fan shroud may gradually tilt downward if screws loosens. Nylock better secures fan shroud. However, new Evan hook largely avoids that problem. Use PETG nozzle as bootstrap to print next one in ABS or Polycarbonate. PETG should last long enough to get through one print. Alternatively, print high temp version BEFORE installing Mosquito. Polymax polycarbonate is highly recommended for hot fins and fan shroud. Bunnies recommend making several sets of polycarb hot fins and fan shrouds for your spares stock. -- f you have not printed previously with Polymax, coat smooth PEI print bed with glue stick, dissolve and spread glue with wet paper towel, dry at 100C to form reliable bonding surface for Polymax. -- Change Log B02M7 Added wider fan shroud based on RHD Bear air nozzle http://www.thingiverse.com/thing:3390107 Added 5025 fan shroud B03 - Version sync with BNBSX. Minor shroud air path cleanup, probably not worth reprinting shrouds if already printed. B03M1 - Fan shrouds and hotend cover hot fins have new "Evan" interlock hook on right side to prevent tilting of extra wide fan shrouds. Hot fin and fan shrouds adjusted for easier fitment and strengthen Evan hook. B03M3 - tightened M2 screw holes in groove adapters for better thread grip. B03M4 - hot fins more tightly conform to mosquito. Added "mosquito helper" planes to further protect melt zone from hot end fan (noctua) airflow. Planes must be printed in high temp material. B04m1 - hot fins further optimized to protect mosquito melt zone from airflow. Clearance between air plenum and mosquito heat block increased. Thicker Sunon 2510 fan will now fit. (Sunon 2510 fan also requires extruder body B04 and wider E3D plane). B04m2 - Changed fan shroud to BS4RHD for better compatibility with vanadium steel nozzle. Low thermal conductivity vanadium steel nozzle requires 20 to 30C increased hot end temperature to fully melt PETG filament. BS4RHD fan shroud adds diffuse, front air flow to better cool print but not overly chill print nozzle. Typical PETG setting with vanadium nozzle and BS4HD shroud is nozzle (1st/latter) 275/285C, bed 85/90C, fan min 50%, min 80%, bridge 80% That is really quite a bit of nozzle temperature boost required to compensate for vandium steel's poor thermal conductivity. Polycarb settings changed to improve layer fusion. Now prints with fan only during bridges and small area layers. B05 - Modified hot fins for greater clearance from Mosquito heat block and tubes so they can better survive prolonged printing of polycarbonate without print fan. Changes also give more space for silicone heat socks and Magnum heat break's insulator. Hot fins intentionally do NOT quite touch each other in this revision. Full contact fins could fuse to each other under high print temperatures. Fan shroud tip are now 2 mm farther from heater block BS6 set screw and square M3 nut added to fan shrouds for more secure mounting screw. Fan shrouds now print more easily with intrinsic supports.

With this file you will be able to print Mosquito Compatibility Kit for BNB MK3S & MK3 Extruders with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Mosquito Compatibility Kit for BNB MK3S & MK3 Extruders.