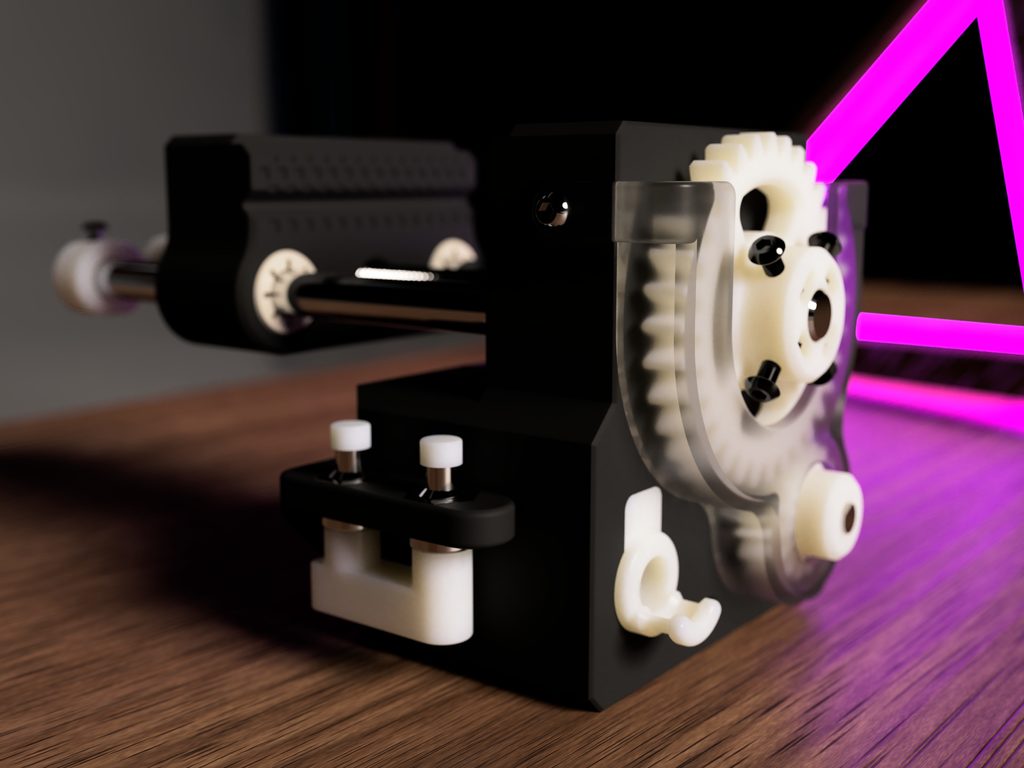

Motorized (PCB) Vise

thingiverse

<h1>Motorized Vise</h1> <h2>Stepper motor assisted vise specifically designed to aid in soldering and light hand work.</h2> <h3>But Why?</h3> I found myself wasting a lot of time messing around with ways of holding wires, PCBs etc. Having a vise that can be easily engaged while both hands are occupied is incredibly valuable to me. <h3>AY, I want one too!</h3> Great! I designed this to use generic 3D printer spare parts so you will probably have everything you need already. If you have a spare Nema 17 stepper motor, an 8mm lead screw (with nut) and an 8mm steel rod you'll have everything you need to create a functioning vise. <h5>3D Workspace & Design Files:</h5> <a href="https://a360.co/3k7U1GS">https://a360.co/3k7U1GS</a> While this vise will work fine with only those components I decided to add some 'nice to haves' to improve the UX. These include a couple of switches and a GX16 Aviation connector to finish off the industrial look. As the electronics are so basic I feel it would be best if I just provide the main vise part. Controlling the vise can be up to you and your needs. Personally I used an ESP-01 module and an A4988 stepper driver running <a href="https://esphome.io/">ESPHome</a>. I decided on this board due to its small size and ability to control the vise via WiFi so I can ask Alexa or the Google assistant to open/close the vise if my hands are full. <em>If there is a demand for my control box designs I can provide the files at a later date.</em> Each part is designed with modularity in mind and as I'm providing all the design files anyone can create parts that attach for their own needs. Such as more buttons, different vise jaws etc. As for the max size the vise can hold, it can be increased or decreased simply by changing the size of the Rods and Lead screw. An important note is all my prototypes were printed on an Ender3, I've spent quite a lot of time dialling the printer in so is accurate to 0.1mm. If your printer is less accurate the designed tolerances may need adjusting. You can try using scaling in your preferred slicer. All parts were printed in 3 different types of PLA and have held up very well, Black, White and Transparent. I've designed the vise jaws to include a 1.8mm lip to hold the average PCB thickness as well as a max 5mm rod chamfer. On the top of the jaws are places to hold 3, 4, 5, 6, 8mm rods. <h4>The cutting info is as stated:</h4> 2x Steel Rod: 130mm 1x Lead Screw: 150mm If I've missed out any information don't hesitate to drop a comment and I hope you find this as useful as I have. :) <em>If anyone who is reading this has experience with designing Helical gears it would be amazing if you posted a remix, I would be very interested to see how they compare.</em>

With this file you will be able to print Motorized (PCB) Vise with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Motorized (PCB) Vise.