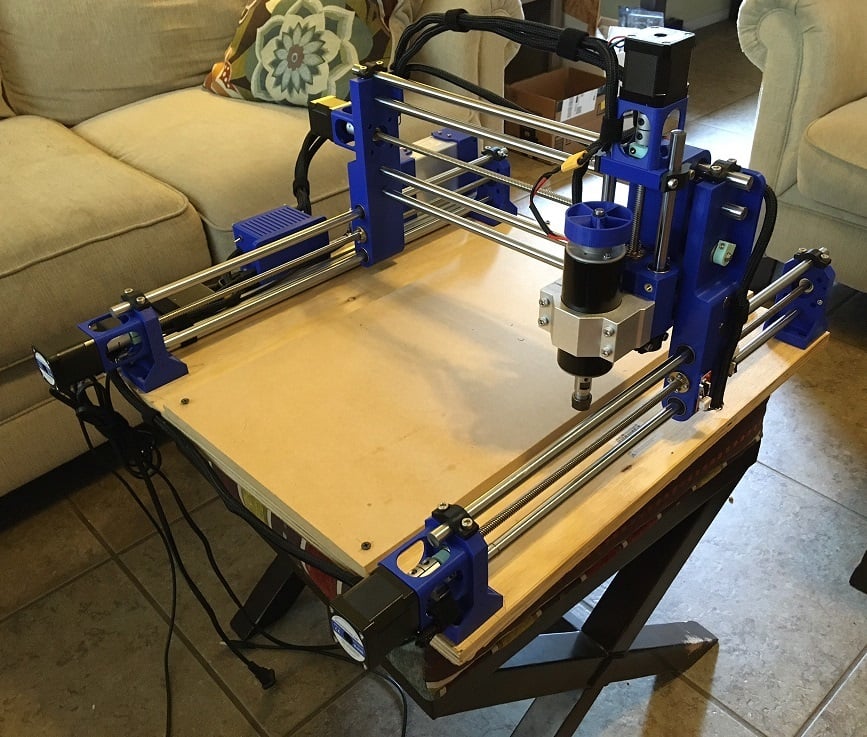

MultiBot CNC v2

thingiverse

This take two on my mostly 3D printed CNC Router. This was heavily inspired by Nikodem Bartnik's DIY Dremel CNC, however all parts are original designs by me. https://www.instructables.com/id/DIY-3D-Printed-Dremel-CNC/ My original project can be found here. https://www.thingiverse.com/thing:4577945 You can read more on this project on my Hack-a-day project page https://hackaday.io/project/176110-multibot-cnc-v2 The goal was to make a low cost CNC machine that used only easily obtainable parts. I tried to make it modular as well so there is plenty of flexibility in the design. This should cost around $350 depending on where you source the parts from. This has a working area of around 365 mm x 465 mm x 75 mm. This new design include the following improvements over the original. - The base is a pre-cut 2 foot by 2 foot 3/4" piece of plywood. This is cheaper, simpler and more ridged then the original aluminum profile base. - Dual 12mm Y axis rods have been added to strengthen the machine. These could be substituted with 16mm rods for even more strength, for a small increase in cost. - Quad 12mm X axis rods have been added to strengthen the machine. These could be substituted with 16mm rods for even more strength, for a small increase in cost. - Clamps have been added to the 8mm lead screws to remove load from the stepper motor bearings. - The Z carriage has been significantly strengthened, and they X rails spaced farther apart to reduce sag on the X axis. - End stops have been added to all axis, this allows for auto squaring of the y axis. - Most 3D printed threads have been replaced with heat set threaded inserts. This adds strength, and makes it easier to disassemble the router. - A second Delrin lead screw nut has been added to each axis, this can be tensioned against the brass nut to remove backlash. The size can easily be adjusted up or down by increasing or shrinking the length of the rods and lead screws. A larger build volume is always nice but there is a linear relationship between build volume and flex (smaller build volume is more solid). You can use any controller and stepper drivers however I am using a low cost CNC shield on an Arduino UNO with GRBL v1.1j and TMC2208 drivers to reduce the noise. Going with DRV8825 or A4988 would probably better if your focus is on machining wood. I highly recommend fitting a cooling fan to the drivers, they can handle a lot more current with active cooling than without. A full parts list can be found at the link below https://docs.google.com/spreadsheets/d/1FOi1EBMshdcwCmGy8l-v2qZ-CG_Ml7QPPqZBUHoxN5E/edit?usp=sharing Here is a part print count: 10 - rail_clamp 8 - clamp_8mm_insert 4 - y_clamp_dual_axis_insert 4 - servo_standoff_insert 4 - coupler_5mm_to_8m (unless you bough couplers) 2 - y_carriage_dual-quad_axis_insert 1 - one of everything else If you print the knife or pen holder then you need to print two holder_standoff's for each. I did a small writeup on how to get endstops working with the CNC shield. https://docs.google.com/document/d/1KOMStGTb-w_KqlAyxvKoIVSi_9OebBm97TLjsE9GJBE/edit Software - GRBL 1.1 for the controller (firmware to control motion of stepper motors) https://github.com/gnea/grbl - Universal GCode Sender to control the machine (send gcode to machine) https://winder.github.io/ugs_website/ - Fusion 360 for CAD/CAM (design and tool path generation) https://www.autodesk.com/products/fusion-360/personal - (alternate) Carbide Create for CAD/CAM, much simpler than Fusion360 but less powerful as well. https://carbide3d.com/carbidecreate/ Guide to CAD/CAM in Fusion360 https://docs.google.com/document/d/1j7bN3EDspqFdop7lzfCD5yb5QjX1i-MaceniBL3TV7U/edit?usp=sharing Printer settings Print with PLA at 30% infill 0.4 mm line width, 0.2 mm layer height, 1.2 mm wall thickness and 1.0 mm top/bottom thickness. All parts are oriented for optimal printing already. And all are designed to print without a brim, raft, or support. Sam put up a great series of videos showing how to build the MultiBot. He has also been a great beta tester and helped sort out several issues. https://www.youtube.com/watch?v=PnldD1Q69RE 2020/11/28 - Updated part list, managed to get most of the 3D models to show up in thingiverse, refreshed all the f3d files to match the latest changes. 2020/12/09 - Added new versions of the models that don't require heat set inserts. See the 'no insert.zip' file. These are setup so you directly screw the bolts into the plastic. It is not as strong and the plastic may crack eventually but it is simpler to assemble. 2020/12/12 - Someone pointed out that the inserts I linked to on AliExpress are thinner then the ones I used in my original design. I went ahead and changed my models to match the thinner inserts, and moved the models with the larger hole in it to a new inserst_larg.zip file. Sorry for the inconvenience but if you find the holes are too large then you will need to reprint a few of the parts. 2020/12/22 - Added support files.zip that contains the following - ugs grbl firmware_2020-12-22.settings, a backup of my grbl settings from universal gcode sender. Could use it as a base for configuring grbl on your machine. - grbl.cps, Fusion 360 GCode post processor - multibot.machine, Fusion 360 MultiBot machine definition - multibot.tools, Fusion 360 tool library, contains my own tools, use as a starting point for your own library. 2021/06/15 - Updated size of insert holes to better match inserts listed in BOM. - Added laser holder and driver board models for a NEJE 30w N40630 laser module. These should work with other NEJE modules that use similar mounting methods.

With this file you will be able to print MultiBot CNC v2 with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on MultiBot CNC v2.