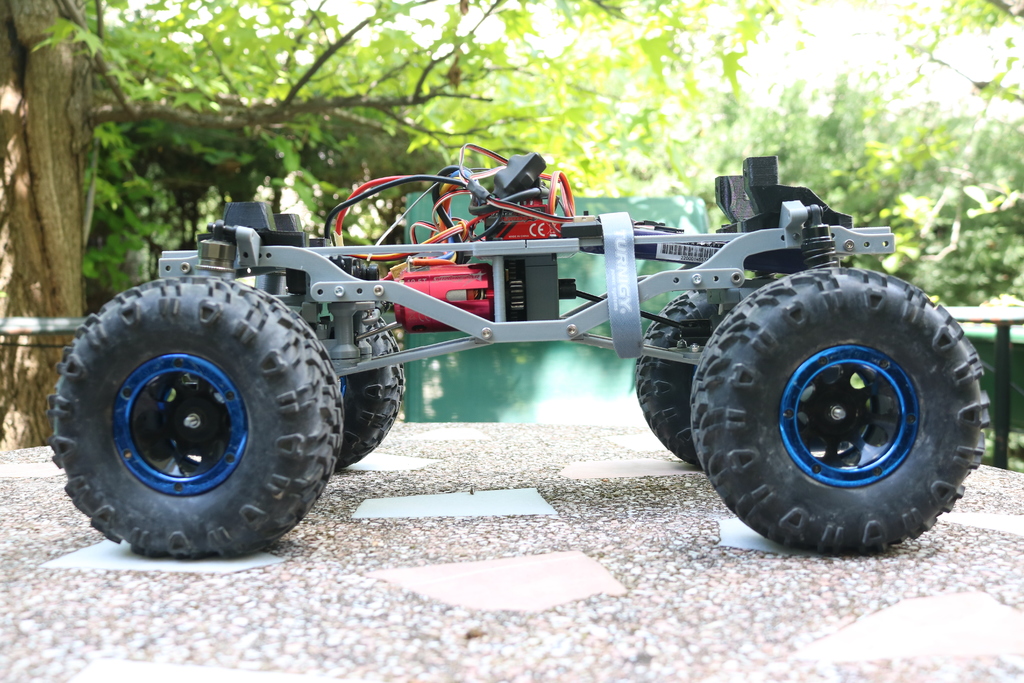

MyRCCar 1/10 Monster /Crawler Chassis with Configurable 270 to 330mm Wheelbase

thingiverse

This is a RC car "hybrid" chassis, maybe not a **monster** at all, maybe not a **crawler** at all, but i think you can "play both roles" quite good with this chassis with its **independent suspension system** in spite of fixed axles and multilink suspension. The shape of **the chassis try to be narrow** to fit where an Axial SCX10 would fit and try to have similar measures. The main goal of this chassis is to have a **great clearance**, so the center of gravity is also higher. This will make the car to roll over if you turn close at high speeds. Also all the **structure is a little over-sized** to be as strong as possible, but maybe this made it a little heavy too. You can see double solid big suspension arms for each wheel. ####ULTRA-NEW: A new video of a [Speed Build Test Drive of the MTC Chassis](https://youtu.be/EprtyTaEj4c) without using gearbox. Calculated top speed 52Km/h... read description of the video for more info. You will also see how the Typical Pickup Body and the chassis resists a rolling... Some scratches in the roof as spected, any other damage. I just used my foot when i reached the car to turn it downside-up! But if you want to see a good video about MTC Chassis then this [Yuran Liu's MTC Chassis Video](https://youtu.be/z6Y_cUs4_Z8) is the one you are looking for :) See also this [video of MTC+TPB highlift](https://youtu.be/tlIHbWKtQcE) ####NEW: Take a look to the [MyRCCar MTC Chassis with the Typical Pickup Body in Action!](https://youtu.be/BoferANebmE) The fun part is that **you can change wheelbase just moving the front or rear platform and bars**. This allows you to displace each axle 10, 20 or 30mm to the front or the back. **The smallest config will have a 270mm wheelbase, from there you can then have 280, 290, 300, 310, 320 and 330** moving one or both axles to the desired position. You will need to displace 10mm or more the front axle if you want to use a motor bigger than 3650. As you can see in the photos, i can't fit perfect my battery in the place for it. If you displace the rear axle you will have more room for your battery. There is just one part wich has different versions, the bottom front/rear cover. This part protects the bottom of the car and also strengths the whole chassis. They are the same for the rear or the front, but you will have four different versions, the first for the "Position 0", would be the one used for the 135+135 (270mm) wheelbase. Position 1, 2 or 3 would be the ones for the 10, 20 and 30 mm displaced axles. If you take a deep look and compare the parts with the ones from the OBTS chassis you will find **the center and front/rear diff housings are the same**. Yes they are, i could find a way to use them in this new model. The F/R housing is upside down this time, and where you should mount the butterfly holder in the OBTS chassis you need to mount the lower arms support in this MTC chassis. There are less options this time about caster or camber. This time i only pre-made the 0º axle inclination for the rear and 6º for the front one, i think this combination is kind of common and works good enough. I spent a lot of work to give a lot of choices in the OBTS chassis and I got very little feedback about them because just Yuran Liu made a working MyRCCar. He needed some parts i did not pre-made also, so **this time i'll make them on demand for those of you who decide to start with this project**. If you want to have **both axles with direction**, you can print the "front platform" twice and find another place for the battery, probably higher wich i think is not a good idea at all. All parts for this new chassis **can be printed in a 200x200 bed**. The longest ones, the central side bars need to be printed in the diagonal of the bed, but it won't be a problem for you if your bed is good leveled. The **sourced parts needed are the same than for a MyRCCar OBTS Chassis**, so you can use them in all models by now. If i can see real interest from people in this chassis i will prepare some new drawings, maybe renders, exploded views, sourced and printed part lists, assembling instructions or more photos or videos. The ESC/Motor im using are not ideal for this kind of truck. I bought some second hand crawling wheels to see how it performs, the chassis mostly, but i realized i can't crawl more than 5min with my trans/ESC/Motor config. This is the only sensored motor/esc i have but 10.5T for the total 3.8KG with the big wheels and the FJCruiser Body i think is too low Turns in the motor and incorrect transmission reduction ratio. On the other hand, with this motor/esc/trans/wheels config i could reach 60km/h or more, but i wont give it full throttle by now. ##NEW 1:4 REDUCTION GEARBOX## As you can see in the previous paragraph the behavour of the car with my Motor/ESC was not good due to the motor getting so hot (90ºC) in aprox 5min. So the only thing i could change without spending more money was the transmission. I had it all in metal, from motor pinion to the wheel, but i have some experience with plastic Mod1 gears and they have worked good for me. ##NEW PARTS IN THIS BUILD## To accomodate this new gearbox you have to replace the center diferential housing. It takes mostly the same space. To be able to choose from normal Center Diff or this new gearbox i had to modify 2 of the parts previously published, they are MRCC_MTC_Platform_Central and MRCC_MTC_Cover_TopCenter. **If you print the new ones you wont need to re-print them if you decide to use the gearbox**. As you can see in the photos and the [VIDEO](https://youtu.be/ElBD_6hXfq4), i have prepared some TPU adaptors to use my FJ Cruiser Body. If you pretend to use this combination prepare your electronics and gearings for the great 3.8kg weight. I hope you like it and someone have the courage to give it a try, it won't be more than 500g in plastic for the chassis and i can help to make some conventional body holders and maybe in the near future i try to make a light truck shell compatible with this chassis. (and i did :) Hope you have seen the new [MyRCCar Typical Pickup Body](https://www.thingiverse.com/thing:2996717)). Also now thanks to lijw interest you can use 188015 or 108015 CVDs. New Lower and Upper arms added with 769mm from pin to pin, as i did with the OBTS chassis ones, i just extended them 5.4mm from the 715 version. I hope lijw can confirm us soon if this new arms in combination with the new rear fixed TypeB C-hub and front C-hub with TypeB front steering block works good enough. See you in [MyRCCar Group](https://www.thingiverse.com/groups/myrccar)!!!

With this file you will be able to print MyRCCar 1/10 Monster /Crawler Chassis with Configurable 270 to 330mm Wheelbase with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on MyRCCar 1/10 Monster /Crawler Chassis with Configurable 270 to 330mm Wheelbase.