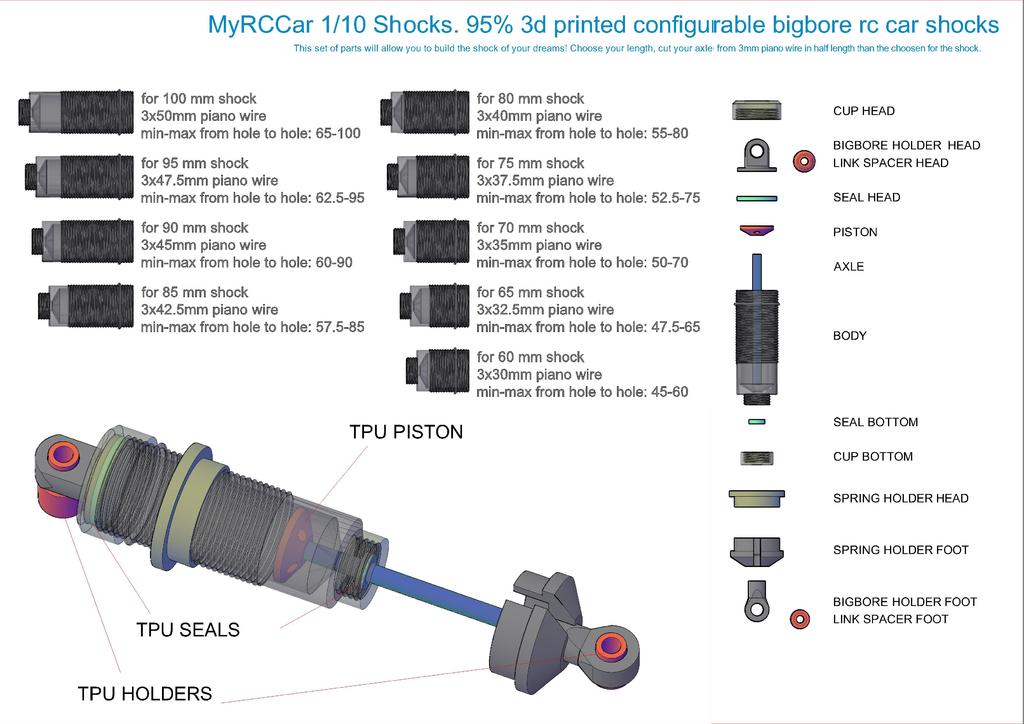

MyRCCar 1/10 Shocks: 95% 3D Printed Configurable Bigbore RC Car Shocks

thingiverse

I'm in Shock!!! I had shocks in the chapter of "could be printed but much better if sourced"... Until now :) Can you imagine why?¿? I have seen a few but not bad ideas about shocks around here in thingiverse, and i thought it was time for me to make my own version. As a little challenge, i have tryed to reproduce the measures and functionality of a real rc shock. That means to contain oil or silicone and be strong and have a spring, strong enough to manage my MTC and OBTS chassis. I'm really really happy with results :) First of all, i did not thought i could print well enough for something printed in PLA to contain a fluid. Ok maybe silicone is not just a fluid, but... Also i was not sure at all if some thorical joints made of TPU could do the work... Of course we need some soft elements here. If you take a look to the dis-assembled picture, there are two blue parts. This are printed in TPU and are MANDATORY. Thanks to those parts the silicone is well contained inside the shock body, very well contained by now :) There will be more than 10 parts for a shock, but just 3 of them need to change for different shock lengths. Those are: The body, the axle (3mm piano wire) and the spring. The body includes a screw and you can adjust spring pre-charge with the provided upper spring holder. I want to apologyze for re-naming some of the parts. I did not have time to research for their real name in spanish or english, so im using my own naming. A MyRCCar Shock is composed of the next parts: - Body (9 different lengths) - Cup Head - Cup Bottom - Seal Head - Seal Bottom - Piston - BigboreHolder Head - BigboreHolder Foot - SpringHolder Head - SpringHolder Foot - LinkSpacerHead - LinkSpacerFoot - Spring (Can use big bore 20mm diammeter ones or 3d printed) - Axle (the only not 3d printed element) Ok to be just a shock, those are 12 3d printed parts plus the spring and the axle... but they work when you assemble them together :) With the provided shock bodies you can make shocks from 60 to 100 mm from eye to eye, bore to bore, hole to hole. For the selected length, for example 100, you will need a half-size 3mm piano wire, so for a 100 mm shock you will need a 3x50 mm axle cutted from 3mm piano wire. And for a 85 mm shock you will need then a 3x42.5mm one. The same happens with springs, for each shock length there is a standard (model1) spring, wich is quite hard... So if you are building a 100mm shock you can use a 80mm spring, the same way for a 85mm shock you must use a 65mm spring. I have tested the shocks also with bigbore standard springs (20mm diameter) and also the screw in the body seems to be compatible with my vandal pre-charge adjusting ring (SpringHolder Head). LinkSpacerHead and Foot are the ones you need to position your shock correctly when using M3 screws to put them in the chassis. I have tested them with sourced springs and they work and fit perfect, the same than sourced ones. I'm now printing a second 100 mm shock to have a pair and put them in the rear of my new pickup! I want to use my 3d printed springs, as they are few mm wider, i will have to do Links longer to have the necessary space for the springs to move freely. So there will be probably soon a new version of Links for 3d printed springs. I can't already believe it... but you have the parts also... will you give it a try?¿? Choose your length, cut your axle and some PLA and TPU later... you have "the shock of your dreams" AHaHhahAHhA :) There are various versions for the piston, with 2, 3, 4, 5 or 6 holes, i recommend you to use the 2 hole version, as im using the 4 holes one and feel little ressistance. About shock compression... I did my best with design to make they able to compress as much distance as possible. Finally you can compress a 100mm shock to 65mm, so those are 35mm travel. For a 70mm shock the travel is 20mm, so we could call that shock a 70/50, and the 100 one a 100/65.

With this file you will be able to print MyRCCar 1/10 Shocks: 95% 3D Printed Configurable Bigbore RC Car Shocks with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on MyRCCar 1/10 Shocks: 95% 3D Printed Configurable Bigbore RC Car Shocks.